Aluminum Tread Plate Sheet 4x8

Aluminum Tread Plate Sheet 4x8 Related Searches

Aluminum Tread Plate 4x8 4x8 Aluminum Tread Plate Aluminum Diamond Plate 4x8 Sheet Aluminum Plate 4x8 Aluminum Tread Plate Sheet 4X8 Sheet Aluminum Diamond Plate Aluminum Sheets 4X8 4x8 Aluminum Plate 4x8 Sheet Diamond Plate Aluminum 4x8 Sheet Aluminum Diamond Plate Aluminum Tread Plate Sheets Tread Plate Aluminum Sheets 1 4 Aluminum Plate 4x8 4x8 Aluminum Checker Plate 3/8 Aluminum Plate 4x8 4x8 Stainless Steel Sheet Stainless Steel 4x8 Sheet 1/4 Inch Aluminum Plate 4x8 1/4 Aluminum Plate 4x8 Aluminum Diamond Plate 4x8 Aluminum Tread Plate Sheet Metal 3 16 Aluminum Plate 4x8 4x8 Aluminum Diamond Plate Stainless Steel 4x8 Sheets 4 X 8 X 1 4 Aluminum Plate Diamond Plate Aluminum 4x8 3/16 Aluminum Plate 4x8 4 X 8 Checker Plate Aluminum Stainless Steel Sheets 4x8 1/2 Aluminum Plate 4x8Aluminum Tread Plate Sheet 4x8 Supplier & Manufacturer from China

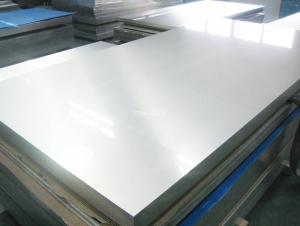

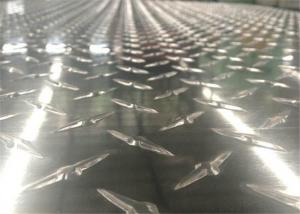

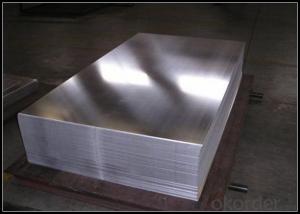

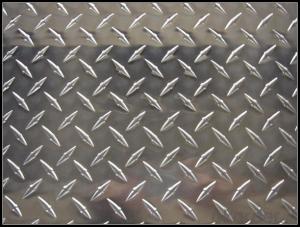

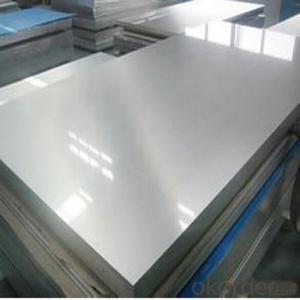

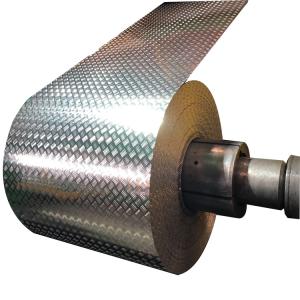

Aluminum Tread Plate Sheet 4x8 is a type of aluminum sheet material that features a raised diamond pattern on one side, providing excellent slip resistance and durability. This product is made from high-quality aluminum, ensuring strength and longevity in various applications. The 4x8 dimensions make it versatile for a wide range of uses, from flooring to wall coverings.The aluminum tread plate sheet 4x8 is widely used in various industries due to its slip-resistant properties and corrosion resistance. It is commonly employed in commercial and industrial settings, such as walkways, ramps, stair treads, and platforms, where safety and durability are paramount. Additionally, it can be used in marine applications, food processing facilities, and anywhere that requires a non-slip surface with a modern aesthetic.

Okorder.com is a leading wholesale supplier of aluminum tread plate sheet 4x8, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum tread plate sheet 4x8 is available in large quantities, allowing businesses to complete their projects efficiently and cost-effectively.

Hot Products