HOT SALES CORRUGATED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | SGCC, DX51D, DX53D, DX54D, etc |

Thickness | 0.12-1.2mm |

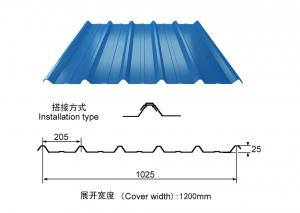

Width | After Briquetting: 790-1025mm |

Waves | 8-15 |

Length | 1000-6000mm |

Zinc Coat | 60g/m2-180g/m2 |

Basic info | roofing sheet is made up of galvanized steel coil or ppgi and other metal steel sheet after rolling cold bending into a variety of wave type pressure sheet. |

Advantage | a.) Attractive and innovative appearance, rich colors, decorative, flexible combination b.) Light weight, high mechanical properties; c.) Anti-earthquake, fire, rain, long life, no maintenance; d.)Installation is simple,shorten the construction period; e.) Environmental protection, etc. |

Application | a.) Industrial and civil buildings, warehouse; b.) Steel structure houses and roof, walls, and decoration, etc. |

- Q: Are steel sheets suitable for high-vibration environments?

- Due to their inherent strength and durability, steel sheets are commonly used in high-vibration environments. Steel possesses excellent mechanical properties, such as high tensile strength and resistance to fatigue, making it capable of withstanding vibrations without significant deformation or failure. Additionally, steel sheets possess the ability to absorb and dissipate vibrations due to their mass and stiffness. This feature enables them to effectively reduce the transmission of vibrations to other components or structures. By absorbing and dissipating the energy generated by vibrations, steel sheets minimize the potential for damage or disruption. Moreover, steel sheets can be customized and produced to meet specific requirements for high-vibration environments. They can undergo reinforcement or be treated with coatings to enhance their resistance to corrosion, wear, and fatigue, thus further enhancing their suitability for such conditions. However, it is crucial to carefully consider the specific characteristics and intensity of the vibration environment when determining the compatibility of steel sheets. Factors such as frequency, amplitude, and duration of vibrations need to be taken into account. In extreme cases, alternative materials or specialized designs may be necessary to ensure optimal performance and longevity. In conclusion, steel sheets are generally well-suited for high-vibration environments due to their strength, durability, and vibration-dampening capabilities. Nonetheless, a comprehensive evaluation of the specific conditions is essential to determine the most appropriate solution for each application.

- Q: What is the difference between a galvanized and aluminized steel sheet?

- The durability and corrosion-resistant properties of galvanized steel and aluminized steel sheets make them widely used in various industries. However, there are notable distinctions between the two. Galvanized steel sheets have a layer of zinc coating that safeguards the underlying steel from rust and corrosion. This process, called galvanization, can be accomplished by immersing the steel sheet in a bath of molten zinc or by electroplating a zinc-rich coating. The zinc layer acts as a sacrificial barrier, meaning it will corrode before the steel, providing excellent rust protection. Galvanized steel finds common usage in outdoor applications like roofing, fences, and automobile parts. In contrast, aluminized steel sheets are coated with an aluminum-silicon alloy layer. This process, known as aluminization, involves immersing the steel sheet in a bath of molten aluminum or applying a thin layer of aluminum-silicon alloy through a continuous hot-dip process. The aluminum-silicon coating offers remarkable heat resistance and corrosion resistance. Aluminized steel is commonly employed in applications where high temperatures are present, such as automotive exhaust systems, heat exchangers, and ovens. To summarize, the primary distinction between galvanized and aluminized steel sheets lies in the type of coating applied to the steel. Galvanized steel is coated with zinc, providing outstanding rust protection, while aluminized steel is coated with an aluminum-silicon alloy, offering superior heat and corrosion resistance. The choice between the two depends on the specific requirements of the application, such as the presence of high temperatures or the need for long-lasting rust protection.

- Q: Can steel sheets be used in outdoor applications?

- Yes, steel sheets can be used in outdoor applications. Steel is a highly durable and weather-resistant material, making it suitable for various outdoor purposes such as roofing, siding, fencing, and construction projects. Its strength and resistance to corrosion make it an ideal choice for enduring harsh weather conditions and providing long-lasting performance.

- Q: Can steel sheets be used for decorative purposes?

- Yes, steel sheets can be used for decorative purposes. They can be shaped, cut, and finished in various ways to create visually appealing designs. Steel sheets are often used in architecture, interior design, and art installations to add a modern and industrial aesthetic to spaces.

- Q: Are the steel sheets suitable for outdoor sculptures?

- Yes, steel sheets are suitable for outdoor sculptures. Steel has high durability, strength, and resistance to weathering, making it an ideal material for withstanding outdoor conditions. Additionally, steel can be easily manipulated and shaped, allowing for intricate and creative sculptures to be crafted.

- Q: Are steel sheets suitable for architectural projects?

- Architectural projects can indeed utilize steel sheets as they offer numerous advantages. Steel, being a versatile and durable material, is highly suitable for such applications. First and foremost, steel sheets possess immense strength, enabling them to bear heavy loads. This makes them perfect for structural elements in buildings. The high strength-to-weight ratio of steel sheets allows for the creation of large and open spaces without the need for excessive supporting columns or walls. Consequently, steel sheets are ideal for constructing expansive interior spaces like atriums, stadiums, and other architectural projects. Furthermore, steel sheets can be easily shaped and formed into various architectural designs. They can be curved, rolled, or bent to fashion unique and intricate structures. Steel's malleability empowers architects and designers to challenge conventional building designs and create visually stunning and innovative structures. Moreover, steel sheets exhibit resistance to corrosion, weathering, and fire, making them suitable for outdoor applications and ensuring the longevity of architectural projects. The durability of steel also translates into minimal maintenance requirements throughout its lifespan, resulting in long-term cost savings. In addition, steel sheets offer a wide range of finishes, textures, and colors, facilitating customization and aesthetic versatility in architectural projects. Whether aiming for a sleek and modern design or a rustic and industrial look, steel sheets can be tailored to meet the desired aesthetic requirements of the project. To sum up, steel sheets are an excellent choice for architectural projects owing to their strength, versatility, durability, and aesthetic appeal. Their ability to withstand heavy loads, be shaped into various designs, resist corrosion and fire, and offer customization options make them a favored material for architects and designers to turn their visions into reality.

- Q: The difference between steel edge sealing strip and steel plate putty water stop belt

- The steel sealing strip is made of pure steel plate and can be divided into galvanized steel sheet, ordinary steel plate and stainless steel water stop belt.The steel plate putty water stop belt is covered with butyl rubber. The main material is a kind of rubber and plastic material with good aging resistance. It has a strong self adhesion, and it does not run in summer. Low temperature in winter, no brittle, and has excellent water, acid and alkali resistance and aging resistance, long service life, the product itself non-toxic, good environment. In order to withstand certain bending and pressure. There are 0.4 or 0.6mm steel plates in the center. The steel plate putty water stopping belt can provide reliable waterproof and anti-seepage function to the building joint. Steel plate putty water stop series products include various specifications and types of products, and can produce various types of steel sheet, putty, water stop belt according to user requirements, to meet the actual needs of the project.

- Q: Can the steel sheets be easily engraved or etched?

- Yes, steel sheets can be easily engraved or etched using various techniques such as laser engraving or chemical etching.

- Q: What are the applications of steel sheets in construction?

- Steel sheets have a wide range of applications in construction due to their exceptional strength, durability, and versatility. Some of the key applications of steel sheets in construction include: 1. Roofing and cladding: Steel sheets are commonly used for roofing and cladding in both residential and commercial buildings. They provide a weather-resistant and long-lasting solution, protecting the structure from the elements. 2. Structural components: Steel sheets are utilized in the construction of structural components like beams, columns, and trusses. The high strength-to-weight ratio of steel allows for the creation of lightweight yet robust structures that can withstand heavy loads and seismic forces. 3. Flooring: Steel sheets are often used as flooring material in industrial buildings, warehouses, and factories. Their smooth surface makes it easy to clean and maintain, while their strength and fire-resistant properties provide a safe working environment. 4. Wall partitions: Steel sheets are commonly employed in the construction of wall partitions due to their stability and sound insulation properties. They can easily be cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets are widely used in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces allow for efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are often integrated into concrete structures as reinforcement. This helps to enhance the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In summary, steel sheets are extensively used in construction for roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an essential component in various construction applications, contributing to the overall safety, longevity, and functionality of buildings.

- Q: What is the average weight of a steel sheet per square meter?

- The average weight of a steel sheet per square meter depends on the thickness and type of steel, but it typically ranges from 7.85 to 8.05 kilograms per square meter.

Send your message to us

HOT SALES CORRUGATED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords