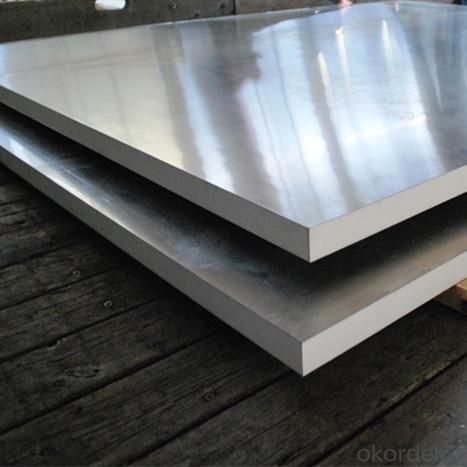

4 Foot By 8 Foot Sheets of Aluminum Hot Sale Aluminum Plates 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Hot Sale Aluminum Plates 6XXX

|

Alloy Number |

AA6061 |

|

Temper |

H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

|

Thickness |

0.1mm – 500mm |

|

Width |

10mm- 2200mm |

|

Standard |

GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications ofHot Sale Aluminum Plates 6XXX

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Hot Sale Aluminum Plates 6XXX

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Hot Sale Aluminum Plates 6XXX

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: Explain the impact of aluminum sheets on the thermal insulation of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can significantly reduce the thermal insulation of a building. They allow heat to transfer easily through them, which can lead to increased heat loss in winter and heat gain in summer. This can result in higher energy consumption for heating and cooling, making the building less energy-efficient. However, when used in combination with proper insulation materials and techniques, aluminum sheets can still be part of an effective building envelope, provided their thermal bridging effects are mitigated.</p>

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags.

- Q: How does the thickness of aluminum sheet affect its strength?

- The strength of an aluminum sheet is directly influenced by its thickness. Generally, a thicker aluminum sheet will possess greater strength compared to a thinner one. This correlation arises from the fact that the thickness of the sheet determines the quantity of material present, ultimately impacting its ability to endure external forces or loads. Typically, the strength of a material is measured based on its capacity to withstand stress without deforming or failing. Thicker aluminum sheets have a larger volume of material, resulting in an increased number of atoms and bonds to counteract forces. Consequently, these sheets exhibit a heightened resistance to deformation or failure, thus rendering them stronger. Furthermore, thicker aluminum sheets boast a higher load-bearing capacity. Consequently, they can endure heavier loads or higher pressures without distorting or failing. The augmented thickness allows for a greater distribution of the load, thereby reducing the stress placed on individual atoms and bonds within the sheet. Nevertheless, it is crucial to acknowledge that there exists a limit to the thickness at which the strength of an aluminum sheet reaches a plateau. Once this threshold is surpassed, further increasing the thickness may not yield significant improvements in strength. This limitation arises from the influence of other material properties of aluminum, such as its crystal structure and grain boundaries, which also contribute to determining its strength. To conclude, the strength of an aluminum sheet is directly linked to its thickness. Thicker sheets possess more material, enabling them to effectively resist deformation or failure under stress. Furthermore, their increased thickness allows them to support heavier loads or endure higher pressures. However, it is important to recognize that there is a limit to the thickness at which the strength plateaus, as other material properties also come into play.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Your 30-35 lb draw bow is slightly underpowered for hunting. Some states regulate the draw weight to around 50 lbs. So that your arrow does damage when it hits. I would recommend a compound bow as they are easier to draw and the power is there. tTe power will affect the arrow as they bend pretty good when released. But all arrows do that.even the glass and wooden arrows. If there is a flaw in the arrow throw it away!!

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Brake cleaner will stain. You need to go to a local auto parts store, like Pep Boys, or Autozone and get a container of Mother's aluminum wheel cleaner and polish. Then go into the aisle with the rags and get a bundle of terry towels and a bundle of baby diaper towels. You will need to use the cleaner/polish on the terry towels first and work in a circular motion, and don't be afraid to apply pressure. You will start to see the cleaner working when it starts turning black, DONT QUIT YET, continue working in a circular motion, and keep at it. After you are happy with the look of the aluminum use the baby diaper towels and wipe them clean in a circular motion also. You may have to repeat to get the desired effect, but in no time your wheels will look like new (or even better)! I have personally hand polished out many small parts, and even the radiator in my 63 impala (which was raw aluminum) with this stuff and it really works.

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

4 Foot By 8 Foot Sheets of Aluminum Hot Sale Aluminum Plates 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords