Aluminum Sheets 4x8 Canada - EN AW-5754 Aluminium Treadplate for Making Caravans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

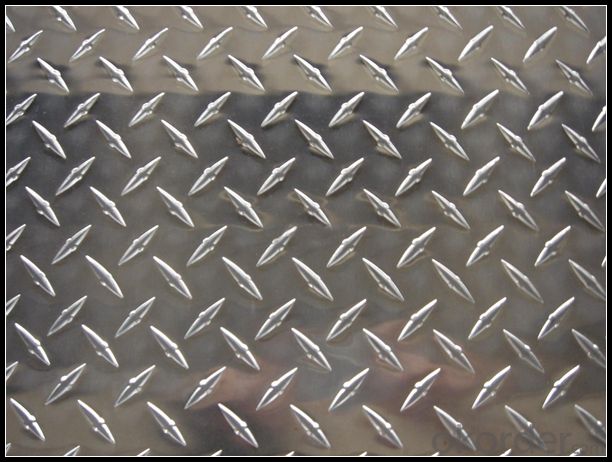

1. Structure of EN AW-5754 Aluminium Treadplate for Making Caravans Description

EN AW-5754 Aluminium Treadplate for Making Caravans is one semi-finished aluminium material. The alloy AA5754 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW-5754 Aluminium Treadplate for Making Caravans

EN AW-5754 Aluminium Treadplate for Making Caravans | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW-5754 Aluminium Treadplate for Making Caravans

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW-5754 Aluminium Treadplate for Making Caravans

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW-5754 Aluminium Treadplate for Making Caravans

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

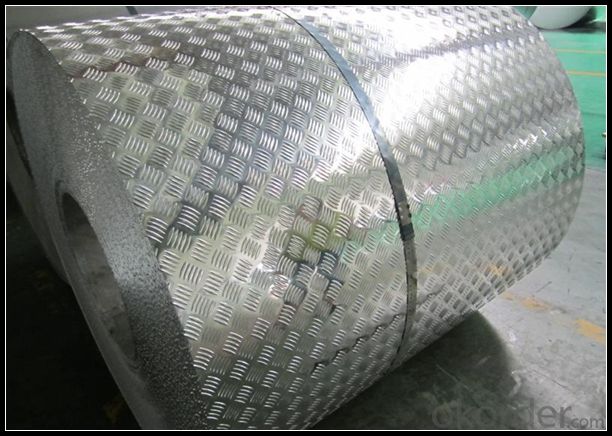

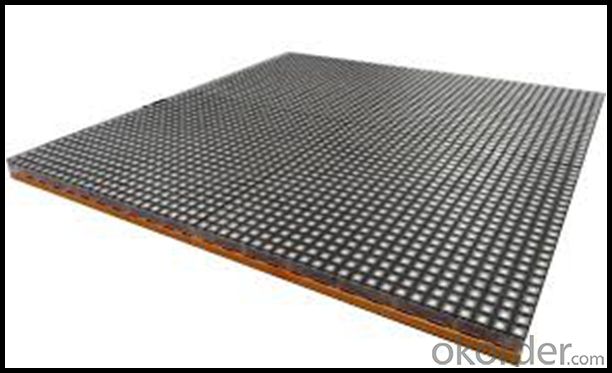

6. Image of EN AW-5754 Aluminium Treadplate for Making Caravans

7. Package and shipping of EN AW-5754 Aluminium Treadplate for Making Caravans

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- The problem is that in an oxygen rich environment, like the air, then aluminum will instantly form a protective coating of aluminum oxide on any freshly prepared surface. So, mechanical sanding or abrasion will be of little help. You could abrade the surface inside of a container where there is no oxygen. That would require the construction of an airtight glovebox, then fill it with N2 or an inert gas. The aluminum oxide coating will dissolve in very basic solutions. Aluminum metal is also very reactive with water. 2Al + 6H2O -- 2Al(OH)3(s) + 3H2(g) In Drano, the basic solution dissolves the Al2O3 coating, which allows the Al metal to react with water producing H2 gas and the agitation needed to help dissolve the clog.

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: What are the different methods of forming aluminum sheet?

- There are several methods of forming aluminum sheet, including rolling, extrusion, stamping, and spinning.

- Q: does anyone know how much aluminium is recycled per year worldwide compared to how much is produced? Even if you know the stats just for Australia or America it would helpthanksxx

- 45% The fact that they can be recycled to produce more cans means there is no excuse for many people to unaware of aluminum recycling. People should also be aware of the benefits that can occur from it. This has created a strong awareness of the recycling nature of cans and this has been a key factor in the growth of this area. In many canteens, dinner halls and corridors across schools and places of work there is a recycling bin. Wherever people can be found drinking from a soft drink can, a specific aluminum recycling bin can be found for cans to be placed in. Compared to the recycling of many other products, it is easier to find a recycle bin. The provisions for recycling soft drink cans have been more progressively tackled and many people are aware of the need to recycle soft drink cans. This has created awareness and knowledge about recycling and this has moved from school to the outside world. One of the major tactics of marketing departments is to target children and get them to pass the message through to all the family. This is usually done in a bad manner but it can also be done promote recycling. You may see people who go around picking up cans that are thrown away without thought and send them to a recycling center. There are some recycling centers that will make payment for numbers of soft drinks that are recycled. This is a way for people to make some money. It would take a phenomenal amount of aluminum recycling to make a fortune. However, it can help the environment and make a small amount of money back so many people can find the motivation to recycle. There are many places that could be a great source of finding soft drink cans that are thrown away: - School playgrounds - The beach - The car park - Parking lots - Busy streets The amount of products that are available to be recycled continues to grow but it is unlikely that they will grow to be more popular than aluminium recycling.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- Mig Welding Aluminum Without Gas

- Q: Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several different methods of surface passivation for aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include anodizing, chromate conversion coating, and organic coating. 1. Anodizing: Anodizing is a widely used method that involves creating a thick protective oxide layer on the surface of the aluminum sheet. This is achieved by immersing the sheet in an electrolyte solution and passing a current through it. Anodizing provides excellent corrosion resistance, improves the surface hardness, and allows for various color options through dyeing. It is commonly used in architectural and decorative applications. 2. Chromate conversion coating: Chromate conversion coating, also known as chemical conversion coating or chromating, involves treating the aluminum surface with a solution containing chromate compounds. This method provides a thin, protective layer that improves corrosion resistance and enhances paint adhesion. It is widely used in aerospace, automotive, and electronics industries. 3. Organic coating: Organic coating refers to the application of a protective layer of organic material, such as paint or powder coating, onto the aluminum surface. This method provides exceptional corrosion resistance and can also offer aesthetic options. Organic coating is commonly used in industries where the aluminum sheets are exposed to harsh environments or require specific colors or finishes. 4. Plasma electrolytic oxidation (PEO): PEO is a relatively newer method that involves immersing the aluminum sheet in an electrolyte solution and passing high-voltage current through it. This process leads to the formation of a ceramic-like oxide layer on the surface, which enhances corrosion resistance, hardness, and wear resistance. PEO is commonly used in applications requiring high-performance coatings, such as aerospace and automotive industries. 5. Passivation with acids or chemicals: Passivation using acids or chemicals involves treating the aluminum surface with a solution that removes impurities and forms a protective layer. This method helps in reducing the reactivity of the surface and enhances corrosion resistance. It is commonly used in industrial applications where aluminum sheets are exposed to harsh chemicals or environments. Overall, the choice of surface passivation method for aluminum sheets depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hardness, and environmental factors. It is important to consider factors such as cost, durability, and the desired performance characteristics when selecting the appropriate method.

Send your message to us

Aluminum Sheets 4x8 Canada - EN AW-5754 Aluminium Treadplate for Making Caravans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords