Brushed Aluminum Sheets 4x8 - AA1050 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

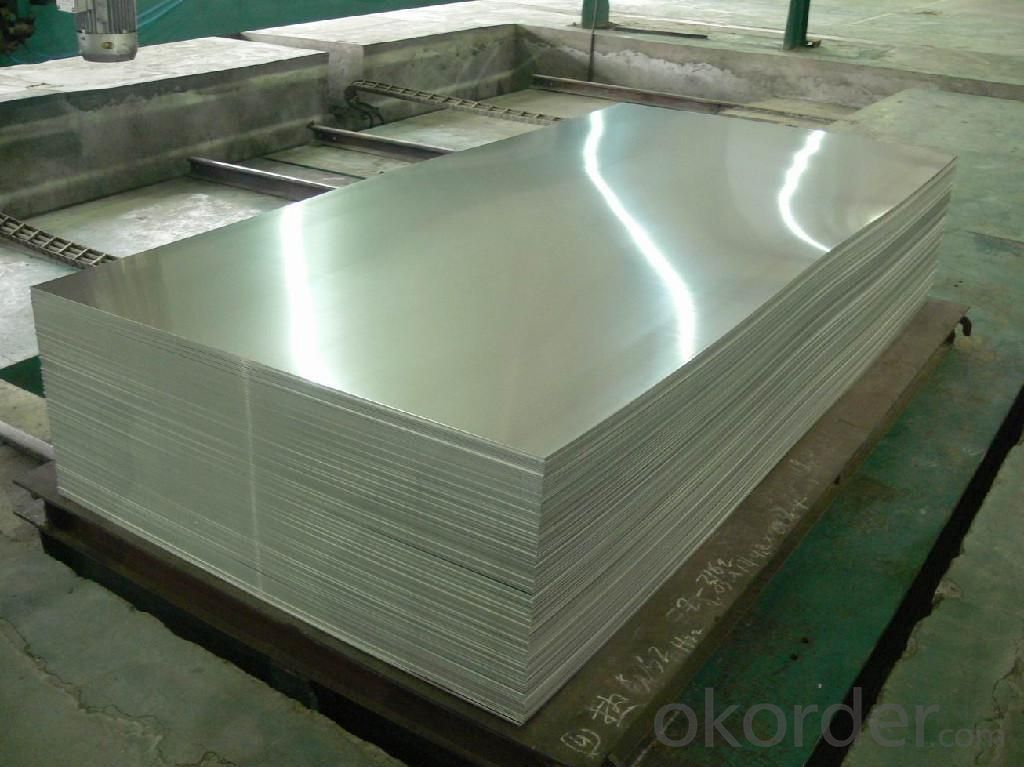

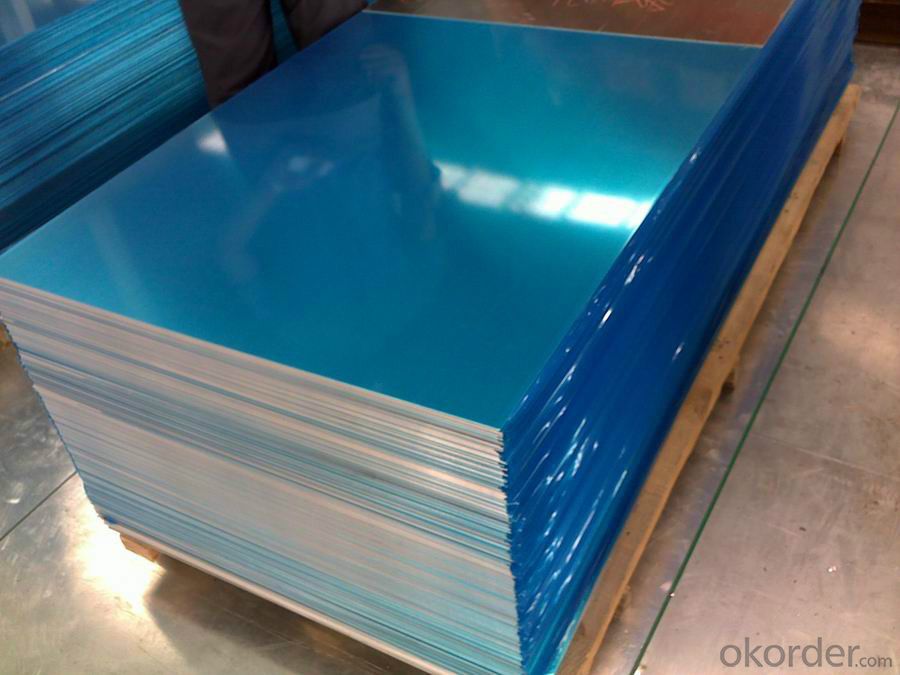

1.Structure of Aluminum Sheets AA1050 Used for Construction Description

Aluminum Sheets AA1050 Used for Construction is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets AA1050 Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA1050 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1050 Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

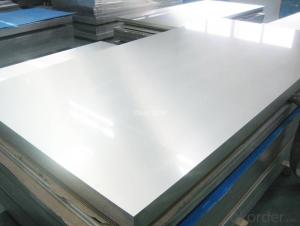

3.Aluminum Sheets AA1050 Used for Construction Images

4.Aluminum Sheets AA1050 Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1050 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1050 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1050 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

C.What is the MOQ?

The MOQ for each size is 4-5 tons.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: What is the maximum temperature resistance of aluminum sheets?

- Aluminum sheets can generally withstand temperatures up to approximately 600 degrees Fahrenheit (315 degrees Celsius), but this may differ due to factors like alloy composition, thickness, and treatment. When contemplating the use of aluminum sheets for high-temperature purposes, it is crucial to refer to the manufacturer's specifications or seek professional guidance.

- Q: Are aluminum sheets suitable for soundproofing applications?

- Aluminum sheets are not typically suitable for soundproofing applications as they have low mass and do not effectively block or absorb sound waves.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Indeed, aluminum sheets prove to be a fitting option for electrical conductivity applications. Possessing a high level of conductivity, aluminum demonstrates an electrical conductivity that is approximately 61% of copper's. Consequently, it has become widely favored for a multitude of electrical and electronic applications that prioritize conductivity. Notably, aluminum sheets find purpose in the fabrication of power transmission lines, electrical cables, bus bars, and heat sinks, among other uses. Furthermore, aluminum boasts attributes such as lightweightness, resistance to corrosion, and commendable thermal conductivity, all of which contribute to its suitability for electrical conductivity applications.

- Q: Are aluminum sheets resistant to impact and vibration?

- Aluminum sheets, in general, show resistance to impact and vibration. The notable feature of aluminum lies in its remarkable strength-to-weight ratio, rendering it a robust and lightweight substance. With commendable mechanical properties, including outstanding resistance to impact and vibration, aluminum sheets frequently find application in various sectors necessitating protection against such forces. Take, for instance, automotive parts, aircraft structures, and building facades. Furthermore, the addition of other elements to aluminum alloys can amplify its impact resistance and diminish vibrations. To sum up, aluminum sheets prove to be a dependable option in enduring the forces of impact and vibration.

- Q: This question asks for a list of the various types of profiles that can be made from aluminum sheets.

- <p>Aluminum sheet profiles come in a variety of types, suitable for different applications. Some common types include: 1. Flat Sheets: These are simple, flat aluminum sheets with no bends or curves. 2. Corrugated Sheets: These have a wavy or ridged pattern, providing strength while allowing flexibility. 3. Perforated Sheets: These have holes punched in a regular pattern, useful for ventilation or decorative purposes. 4. Embossed Sheets: These have a raised pattern on the surface, often used for aesthetic or functional reasons. 5. Extruded Profiles: These are complex shapes created by pushing aluminum through a die, suitable for structural applications. 6. Expanded Metal Sheets: These have a diamond-shaped pattern, providing strength and rigidity. 7. Checkered Plates: These have a raised, non-slip pattern, often used for flooring. Each type has its own specific uses and properties, and the choice depends on the requirements of the project.</p>

- Q: What are the different methods of surface cleaning for aluminum sheet?

- Some different methods of surface cleaning for aluminum sheet include mechanical cleaning, such as scrubbing with a brush or abrasive pads, chemical cleaning using solvents or acids, and electrochemical cleaning using an electric current to remove contaminants.

- Q: What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets depends on the thickness and dimensions of each sheet. In general, the density of aluminum is about 2.7 grams per cubic centimeter (g/cm³). To calculate the density of 101 aluminum sheets, you would need to know the mass and volume of each sheet. By dividing the total mass of the sheets by their total volume, you can determine the density.

Send your message to us

Brushed Aluminum Sheets 4x8 - AA1050 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords