Wholesale 5052 3003 6061 pointer/lentil/orange peel patterned aluminum sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

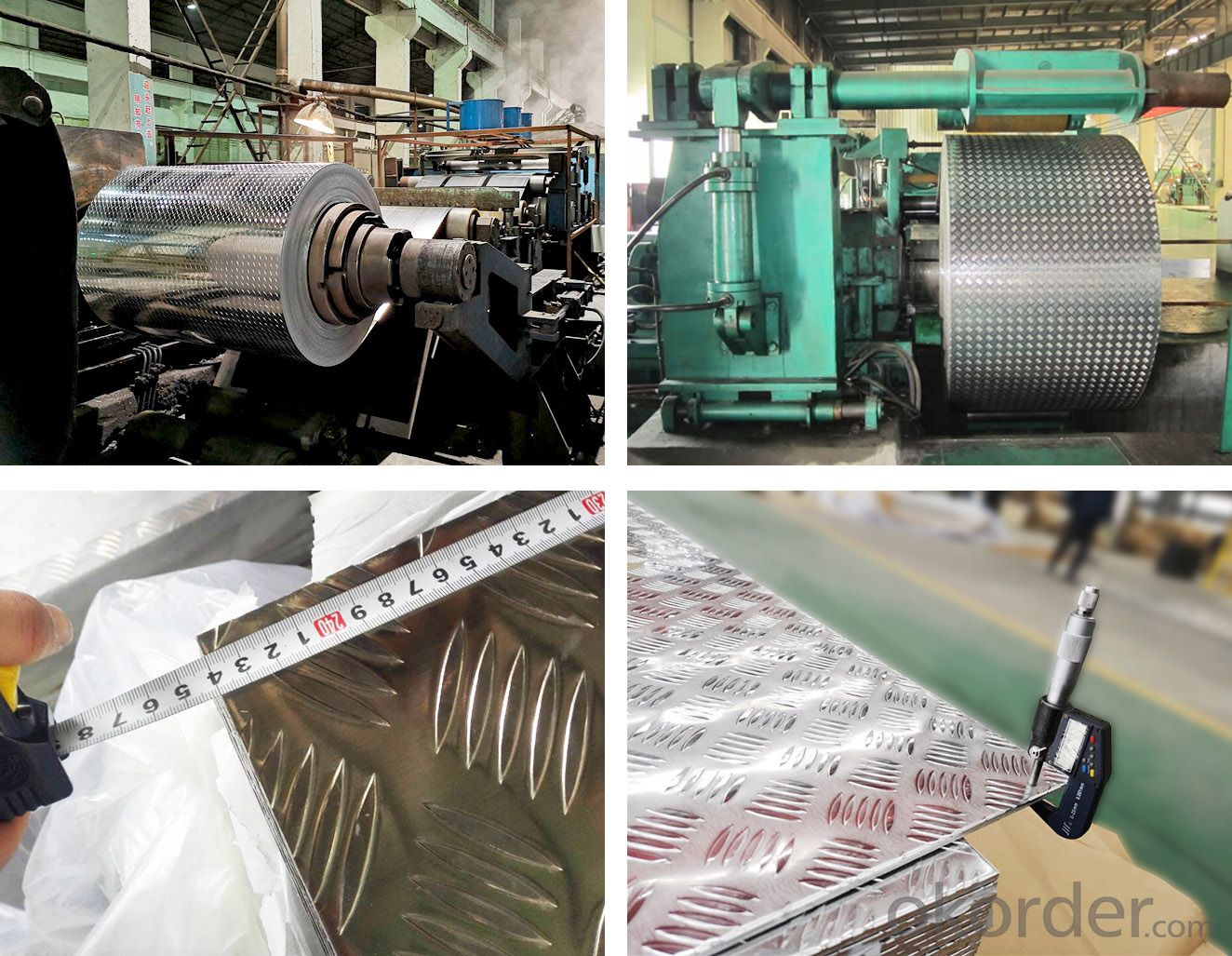

Patterned aluminum sheet is made of aluminum sheet through external mechanical processing. It is rolled on the basis of aluminum flat sheet with a roller press to form a convex pattern on the surface of the aluminum flat sheet. Common patterns of patterned aluminum sheet include one rib, two ribs, three ribs, five ribs, lentils, pointers, orange peel embossed aluminum sheet, etc.

Common alloys for patterned aluminum sheet: 1060, 3003, 5052, 5083, 6061 and other aluminum alloys

The use of patterned aluminum sheets is very extensive: ships, elevators, stairs, bloodless warehouses, floors, packaging, refrigerators, air conditioners, carriages, platforms, packaging pipes, display racks, a series of hanging beams, table legs, decorative strips, handles, wiring pipes and covers, chair tubes, etc.

Embossed aluminum sheet specifications:

| Alloy | 1060, 1060, 3003, 5052, 5083, 6061, etc |

| Thickness | 0.5-6mm, customizable |

| Width | 20-2650mm, customizable |

| Length | 100-16000mm, customizable |

| Technology | cold drawing, cold rolling, hot rolling, forging |

| Embossed pattern | lentil pattern, diamond pattern, five stripes, small five stripes, large five stripes, three stripes, one stripe, teardrop pattern, pointer pattern, orange peel pattern, etc., or customizable |

| Color | gold, red, black, silver, blue, rose gold, incense Colors such as benzene or customized |

| Coatings | PVDF, PE, etc |

| Packing | Internal: packed with plastic protective film to protect each piece |

| External | wrapped in waterproof kraft paper into bundles |

Advantages of aluminum patterned sheet:

1. Accurate size, good anti-slip effect, wide range of applications;

2. Strong plasticity, easy to form, excellent processing performance;

3. Embossed aluminum sheet can form a dense and solid oxide film on the aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance;

4. Good elongation and tensile strength, fully able to meet normal processing requirements (stamping, stretching), high formability;

5. The surface quality of the patterned aluminum sheet is good, without oil spots, waves, scratches, roller marks, neat cutting edges, and no burrs.

What services can we provide?

Accepted delivery terms: FOB, CIF, CFR, CNF, EXW;

Accepted payment currencies: US dollars and RMB;

Accepted payment methods: T/T, L/C, MoneyGram, credit card, PayPal, Western Union;

- Q: What are the limitations of using aluminum sheet?

- There are several limitations to using aluminum sheet. Firstly, it has a lower strength-to-weight ratio compared to other materials like steel. This means that aluminum sheets may not be as strong and durable in certain applications. Additionally, aluminum is prone to corrosion, especially in harsh environments, so proper protective coatings or treatments are necessary. Aluminum sheets also have limited formability compared to materials like steel, which can impact their use in certain complex shapes or designs. Lastly, aluminum sheets can be more expensive than other materials, which may affect their affordability in certain projects.

- Q: What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: Aluminum shallow pattern boardThe shallow pattern board of aluminum alloy is one of the excellent building decoration materials. It is exquisite pattern, color appearance, has the common advantages of ordinary aluminum plate, the stiffness is increased by 20%, anti fouling, anti scratch, anti abrasion ability has been improved, especially the increase of three-dimensional pattern and beautiful color, make the building more brightly.Aluminium alloy decorative panels: aluminium and aluminium alloy corrugated platesAluminum and Aluminum Alloy corrugated plate is widely used in the world of decorative materials, it is mainly used for wall decoration, can also be used for roofing, surface chemical treatment can have a variety of colors, good decorative effect, but also has a strong reflection of the light, very durable, the service life of up to 20 years. And it has a variety of colors, both decorative effect, but also has a strong ability to reflect sunlight. It can resist fire, moisture and corrosion.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: how to avoid oxidation of aluminum sheet after wire drawing?

- leave it alone after wire drawing!aluminum sheet will formulate a layer of dense oxide film. So you don't need to worry about it! Don't often polish the aluminum wire, or they will be more and more slimsy, the oxide film is used for avoiding reoxidation.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used as reflective surfaces due to their high reflectivity and low emissivity properties.

- Q: Are aluminum sheets suitable for marine hulls?

- Yes, aluminum sheets are suitable for marine hulls. Aluminum is a popular choice for boat construction due to its many advantageous properties. Aluminum is lightweight, which allows for better fuel efficiency and increased speed. It is also highly resistant to corrosion, making it ideal for prolonged exposure to saltwater. Additionally, aluminum offers excellent strength and durability, ensuring the structural integrity of the hull. Moreover, aluminum can be easily formed into intricate shapes, allowing for innovative hull designs. Overall, aluminum sheets are a reliable and efficient choice for marine hulls, providing a strong and corrosion-resistant structure that enhances the performance and lifespan of the boat.

- Q: Are aluminum sheets magnetic?

- No, aluminum sheets are not magnetic. Aluminum is a non-magnetic metal, which means it does not have any magnetic properties. This is because aluminum does not contain any magnetic elements, such as iron or nickel. Therefore, aluminum sheets do not attract or interact with magnets.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- it does it is just too thin to hold the heat once the heat source has been removed

- Q: How do aluminum sheets perform in terms of machinability?

- Known for their excellent machinability, aluminum sheets can easily be cut, drilled, and shaped using various machining processes such as milling, turning, and drilling. Compared to materials like steel, aluminum has a low melting point and is relatively soft, making it more manageable to work with. Additionally, aluminum sheets offer good chip control, resulting in smaller and more manageable chips during machining. This not only reduces the risk of tool breakage but also improves the overall efficiency of the machining process. Furthermore, aluminum sheets possess exceptional thermal conductivity, effectively dissipating heat generated during machining. As a result, tool wear is minimized, and the life of the tool is prolonged. With their ease of machining and versatility, aluminum sheets find wide applications across various industries.

Send your message to us

Wholesale 5052 3003 6061 pointer/lentil/orange peel patterned aluminum sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords