1/2 Aluminum Plate 4x8

1/2 Aluminum Plate 4x8 Related Searches

1/4 Aluminum Plate 4x8 1/4 Inch Aluminum Plate 4x8 Aluminum Plate 4x8 1 4 Aluminum Plate 4x8 3/8 Aluminum Plate 4x8 4x8 Aluminum Plate 1/4 Aluminum Diamond Plate 4x8 3/16 Aluminum Plate 4x8 4x8 1/8 Diamond Plate Aluminum 4x8 1/8 Aluminum Diamond Plate 4x8 Aluminum Diamond Plate 1/8 1/8 Aluminum Plate 1/8 Aluminum Diamond Plate 4'X8' 4x8 1/4 Diamond Plate Aluminum 1/2 Aluminum Plate 5/8 Aluminum Plate 4' X 8' X 1/4 Aluminum Plate 4x8 1/4 Aluminum Diamond Plate Aluminum 1/2 Plate Aluminum 1/8 Plate Aluminum Plate 1/8 12 X 12 X 1/8 Aluminum Plate 1/8 Inch Aluminum Plate 1/8 In Aluminum Plate 4x8 1 8 Aluminum Diamond Plate 1/2 Inch Aluminum Plate 4x8 Aluminum Diamond Plate 1 8 Aluminum Diamond Plate 4x8 1/4 Aluminum Plate 3 16 Aluminum Plate 4x81/2 Aluminum Plate 4x8 Supplier & Manufacturer from China

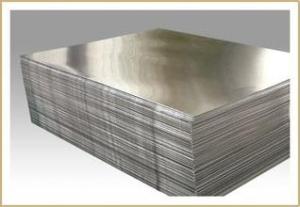

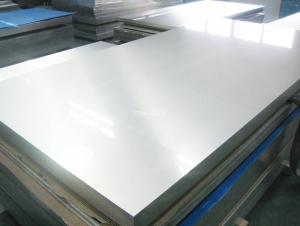

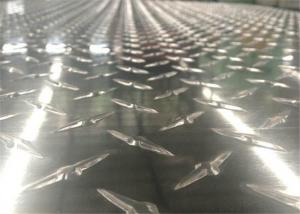

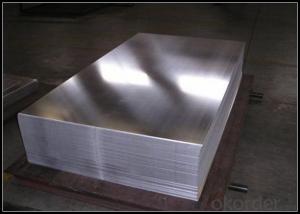

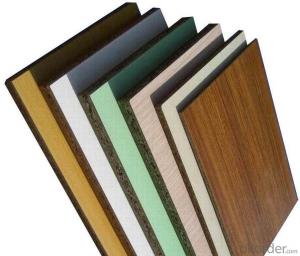

1/2 Aluminum Plate 4x8 is a popular choice among construction and manufacturing industries due to its durability and lightweight properties. This type of aluminum plate is known for its strength and resistance to corrosion, making it an ideal material for various applications.The 1/2 Aluminum Plate 4x8 is widely used in a range of industries, including aerospace, automotive, and architectural projects. Its versatility allows it to be employed in the creation of structural components, decorative elements, and even in the production of various machinery parts. This product's ability to withstand harsh environmental conditions and its ease of fabrication make it a go-to option for professionals seeking a reliable and efficient material.

Okorder.com is a leading wholesale supplier of 1/2 Aluminum Plate 4x8, offering a vast inventory to cater to the diverse needs of clients. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 1/2 Aluminum Plate 4x8 they provide meets the highest industry standards.

Hot Products