8011 3105 H14/H16 painted aluminum closure sheet is suitable for cosmetic bottle caps

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

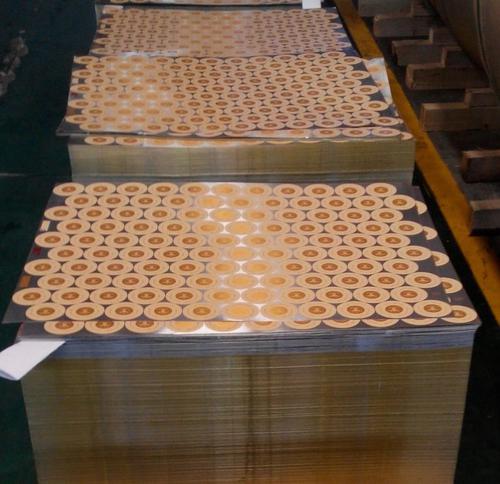

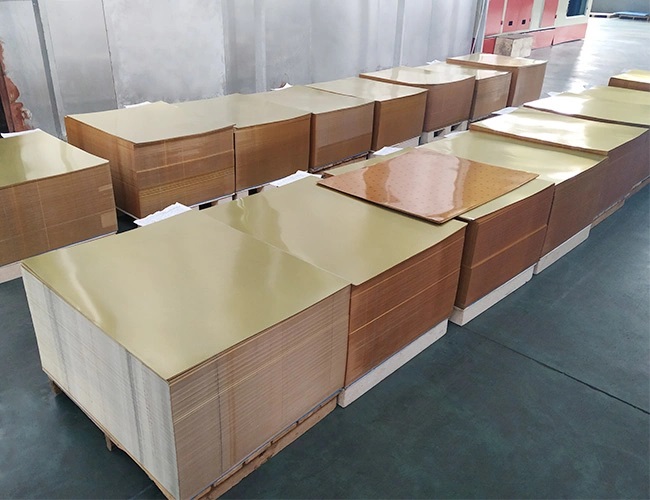

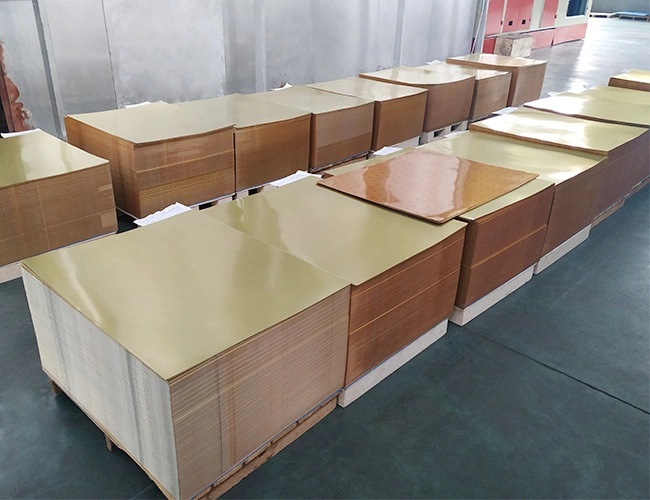

The material selection of cosmetic bottle caps is important, considering processability and environmental protection. Common materials are plastic, metal and glass. Painted aluminum closure sheets can improve corrosion resistance and protect the safety of cosmetics. Aluminum bottle caps have good sealing and beautiful appearance, and are often used in products such as lotions, creams, and perfumes.

8011 3105 Dos treated aluminum sheets are commonly used in cosmetic bottle caps. They are light in weight, easy and economical to recycle, have good barrier properties, good formability, and a bright surface, making them suitable for decoration.

Color coated and DOS treated aluminum sheet for cosmetic bottle caps Specifications:

| Alloy | 8011 3105 |

| Temper | H14, H16 |

| Thickness and tolerance | 0.19-0.24mm (+/-0.005mm) |

| Width and tolerance | 400~2100mm (+0.5mm, -0mm) |

| Length and tolerance | 400-16000mm (+0.5mm, -0mm) |

| Type | sheets |

| Surface | treatment Aluminum surface is treated with phosphochromate and DOS. |

| Application | Bottle caps, closures and vials for pharmaceutical industry. Anti-theft closures for pharmaceutical industry. Lids and containers for cosmetic industry. |

| MOQ | 1-3 tons per model |

| Packaging | Export wooden sturdy packaging box |

8011 3105 painted aluminum closure sheet Chemical composition:

| Alloy | Fe | Si | Cu | Mg | Mn | Cr | Zn | Ni | Ti | Other | Al |

| 8011 | 0.6-1.0 | 0.5-0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | - | 0.08 | 0.15 | Remain |

| 3105 | 0.7 | 0.6 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | - | 0.1 | 0.15 | Remain |

Features of painted aluminum closure sheet for bottle caps:

1. Corrosion resistance

2. Good sealing to avoid external pollution

3. Exquisite appearance, can be painted in different colors according to different customer needs

4. Lightweight and easy to carry

5. Easy to open and anti-theft

6. Green and environmentally friendly

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- Death Cab For Cutie's What Sarah Said: And It Came To Me Then That Every Plan Is A Tiny Prayer To Father Time As I Stared At My Shoes In The Icu That Reeked Of Piss And 409 And I Rationed My Breathes As I Said To Myself That I'd Already Taken Too Much Today As Each Descending Peak Of The Lcd Took You A Little Farther Away From Me Away From Me Amongst The Vending Machines And Year-old Magazines In A Place Where We Only Say Goodbye It Stung Like A Violent Wind That Our Memories Depend On A Faulty Camera In Our Minds But I Knew That You Were A Truth I Would Rather Lose Than To Have Never Lain Beside At All And I Looked Around At All The Eyes On The Ground As The Tv Entertained Itself 'cause There's No Comfort In The Waiting Room Just Nervous Pacers Bracing For Bad News And Then The Nurse Comes Round And Everyone Will Lift Their Heads But I'm Thinking Of What Sarah Said That love Is Watching Someone Die

- Q: This question asks for the steps to take in order to accurately measure the dimensions of an aluminum sheet before purchasing one.

- <p>To measure the dimensions of an aluminum sheet for purchase, first, ensure you have a measuring tape or a ruler. Measure the length and width of the sheet from one corner to the opposite corner, making sure to measure along the longest and widest sides. Record these measurements in the same unit of measurement used by the supplier (commonly inches or centimeters). If the sheet is not a perfect rectangle, measure the diagonal to confirm the dimensions. Note any irregularities or variations in thickness that might affect the intended use. Once you have these measurements, compare them with the available options from the supplier to select the appropriate size.</p>

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Aluminum sheets are indeed suitable for food preparation surfaces. They are a lightweight and durable option extensively utilized in the food industry. Being non-toxic and non-reactive, aluminum does not pose any risk of releasing harmful chemicals upon contact with food. Moreover, aluminum sheets are highly convenient to clean and maintain, making them a preferred choice for both commercial and home kitchens. Furthermore, aluminum boasts excellent heat conductivity, ensuring even cooking and baking. Nevertheless, it is worth mentioning that aluminum may react with acidic or salty foods, resulting in a metallic taste. To prevent this, it is advisable to place a layer of parchment paper or a silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- In the novel, developed from the original screenplay (which featured information that did not end up being mentioned in the film), Scotty was already aware that the chap he gave the transaprent aluminium formula to was recorded as its inventor. Therefore, the plot as intended suggested looped or self-generating causality. This is the outcome referred to in other predestination paradoxes, like the one about going back in time 100 years and becoming your own great-grandfather. The character in the film who Scotty gives the formula to is called Marcus Nichols. he was played by an American actor called Alex Henteloff. For reasons of brevity or simplicity of plot, the film leaves the viewer thinking that Scotty et al didn't know who the inventor was, but Scotty does have the line How d'you know he wasn't the man who invented it?, delivered to Dr McCoy, which could be taken as an indication that Scotty DID know and was just being a smart-**** to McCoy. As a thought experiment, this wouldn't prove the existence of multiple universes, just that the outcome was possible without changing their own future. Proof would require more information that is also missing from the screenplay and film. In reality, there is no such thing as transparent aluminium, but there are aluminium-based ceramics which are transparent.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- Aluminum rims are a whole lot better on the mechanical stand point, they are lighter, usually stronger (depending on the alloy) and they allow for better heat disapation. Lighter rims will save gas money (nothing you will notice, maybe an extra mile/tank, if that). Depending on the alloy used in the aluminum rims, they are usually stronger and can take more froce abuse, just as long as they don't get scuffed up, ect. With the better heat disapation. When the brakes heat up, the heat is sent out ever direction, mostly through metal. Aluminum (alloy) is a great conductor of heat. So when the brakes heat up, the aluminum rims will absord much of this heat, and the outside air will be able to cool the rim faster then the brakes themselves, but the brakes will stay cooler this way. Brakes that are running cooler, will last longer then brakes running hot. You will have less of a chance of brake fade a condition where the brakes get to a point of being to hot, they don't function at all, or its hard to stop the vehicle. It will also extend the brakes over all life, in some cases up to 40-50%. I had stock steel rims in my truck, small rims for a small truck, and whenever I was doing highway driving, i would get brake fade under high speed braking. When I switched to aluminum rims, I have not had brake fade since, I don't know about the life on the pads, as I switched the rims, before I wore a set down. I picked up a set of 4 5spoke rims from an Explorer and put them on my ranger, I paid $80 for the 4 and they look in pretty good shape, little corrosion. A down side to aluminum rims is corrosion, they corrode easier, and can cuase discolouration of the rim itself, or can cause leaky tires if it corrodes around the bead seat, which it usually does. Its a fair trade off however.

- Q: What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

- Q: What are the different surface patterns or textures available for aluminum sheets?

- Some of the different surface patterns or textures available for aluminum sheets include smooth, brushed, hammered, embossed, and diamond plate.

- Q: Is there any reason to believe flushing aluminum foil down the toilet is a bad idea?

- sure ,the problems not the material thats not going to rot or move after it hits a bend in the sewer pipe or the plastic pipe in the wall ,its the stuff that will refuse to go down the pipe thats got a drag spot with the foil in the bend stopping the crap,, if you did this buy some plumbers acid at the home depot store and wear gloves and pour it down that drain and leave for a while then flush once wait then see if it comes back into the bowl, if not wait a little more then reflush

- Q: This question asks for methods to preserve an aluminum window and prevent rust or corrosion.

- <p>To maintain an aluminum window and prevent rusting or corrosion, follow these steps: Regularly clean the window with a mild detergent and water to remove dirt and grime. Avoid using abrasive cleaners or tools that could scratch the surface. Apply a protective coating or sealant designed for aluminum to shield it from moisture and environmental factors. Ensure proper drainage around the window to prevent water accumulation. Regularly inspect the window for signs of damage or corrosion and address any issues promptly. By following these maintenance practices, you can prolong the life of your aluminum window and keep it in good condition.</p>

Send your message to us

8011 3105 H14/H16 painted aluminum closure sheet is suitable for cosmetic bottle caps

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords