1050 1060 1070 3003 CC/DC Aluminum circles are used to make cookware/lighting/traffic signs

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum circles, as the name suggests, are aluminum materials with a circular shape. It is mainly made of aluminum alloy. They are usually made by stamping or cutting aluminum plates and have good conductivity, corrosion resistance and machinability. Common alloy series include 1 series, 3 series, 5 series, 6 series and 8 series, among which 1 series (such as 1060, 1070), 3 series (such as 3003), 5 series (such as 5052, 5083) and 6 series (such as 6061, 6063) are the most common.

CC/DC aluminum circle specifications:

| Alloy | 1060, 1050, 1070, 1100, 3003, 5052, etc. |

| Temper | O/Ho, H12, H14, H18, H24, hard, soft, stretching |

| Process | cold rolling or hot rolling |

| Thickness | 0.2-160 mm |

| Diameter | 100-1250 mm (diameter tolerance: +/-2 mm) |

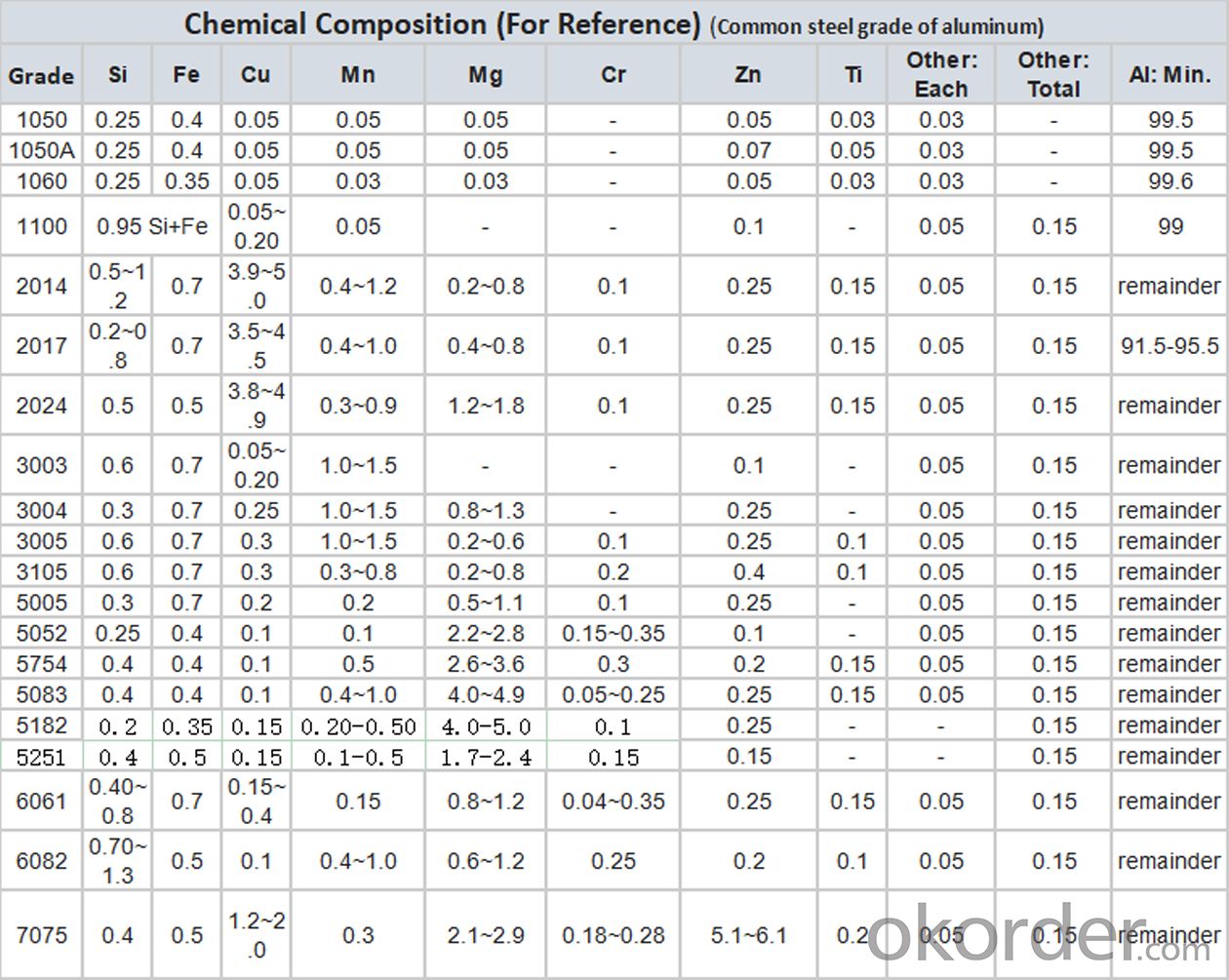

Chemical composition:

Application areas of aluminum disc:

Aluminum circles have a wide range of applications, mainly including electronics, daily chemicals, medicine, culture and education, and auto parts. Aluminum disc also play an important role in electrical appliances, insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other fields. For example, in kitchenware, aluminum circles are used in the manufacturing process of products such as non-stick pans and pressure cookers; in hardware products, aluminum discs are also used in the production of products such as lampshades, water heater shells, and stretch tanks.

Aluminum Plates and Rounds Depending on the usage, aluminum rounds with different thickness, diameter and alloy composition can be selected to meet specific needs.

FAQ:

Q1: Where is your factory located?

A1: Our factory is in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Equipped with various machines, such as aluminum plate machine, aluminum round machine, embossed aluminum coil machine, aluminum roof sheet machine, kraft paper/polysurlyn/pvc film coated aluminum coil machine, aluminum foil machine, etc.

Q2: What are the main products of your company?

A2: Our main products are aluminum plates/sheets, aluminum foil, aluminum coil, aluminum round/circle, aluminum roof sheet, aluminum coil with blue pvc film, embossed aluminum plates/sheets, color coated aluminum coil/sheets, aluminum tubes, aluminum wires, aluminum rods, PS/CTP sheets, etc.

Q3: How do you control quality?

A3: Factory test certification is provided with the goods, and third-party inspection can be provided.

Q4: How can I get your quotation?

A4: Please mention alloy and state, application, thickness, tensile strength, elongation, etc., we will quote as soon as possible.

Q5: How about the delivery time?

A5: Usually about 7-35 days, depending on different order requirements.

Q6. Can you provide samples?

A6: Yes, small samples are free, freight collect.

Customized samples take about 5-7 days.

- Q: Can aluminum sheets be used for furniture manufacturing?

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications such as tables, chairs, cabinets, and shelves. Its versatility allows for different designs and finishes, making it a popular choice in modern and contemporary furniture styles. Additionally, aluminum's recyclability makes it an environmentally friendly option in the furniture industry.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: I have an aluminum block engine in my wakeboard boat which is built for the lakes, now i live on salt water and was wondering the effect saltwater would have on the engine block as water goes through to cool it.

- Salt okorder /

- Q: What are the different forming methods for aluminum sheets?

- Aluminum sheets can be shaped using various forming methods. These methods encompass: 1. Roll Forming: By passing the aluminum sheets through a series of rollers, they gradually take on the desired form. Roll forming is commonly employed to produce elongated shapes like channels or rails. 2. Press Forming: This technique involves utilizing hydraulic or mechanical presses to exert force on the aluminum sheet, resulting in the desired shape. Press forming is often favored for creating intricate shapes with precise tolerances. 3. Stretch Forming: The aluminum sheet is clamped at its edges and then stretched over a die, causing it to conform to the die's shape. Stretch forming is frequently utilized to manufacture curved or contoured parts. 4. Deep Drawing: This method entails inserting an aluminum sheet blank into a die and using a punch to force the material into the die cavity, creating a hollow shape. Deep drawing is commonly employed for producing cylindrical or box-shaped parts. 5. Hydroforming: Hydraulic pressure is employed to shape the aluminum sheet against a die. Hydroforming is particularly advantageous for crafting complex shapes with smooth surfaces. 6. Incremental Sheet Forming: This technique involves a CNC machine moving a small tool over the aluminum sheet's surface, gradually shaping it by applying localized pressure. Incremental sheet forming is often employed for prototyping or small-scale production. These forming methods offer distinct advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and production volume.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- contain more water and activated

- Q: What does exterior wall imitate aluminium paint have? Imitate aluminium plate paint is fluorocarbon paint?

- The exterior walls are painted with aluminium and plastic panels, and only fluorocarbon metal paint is used. The fluorine content determines the service life;The construction technology of fluorocarbon metal paint is relatively complex, and the price is more expensive, generally including the construction is roughly equivalent to more than half the price point to use aluminum plate;

- Q: Can aluminum sheets be bent?

- Indeed, the bending of aluminum sheets is possible. Aluminum, being a remarkably pliable metal, can be effortlessly manipulated and molded through methods like bending, rolling, or folding. To achieve a particular angle or curve, the procedure for bending aluminum sheets entails the application of force onto the metal. This can be accomplished using specialized equipment like a brake press or through manual techniques. The adaptability of aluminum renders it a favored option for a variety of applications in the construction, automotive, and aerospace sectors, where bending or shaping is necessary.

- Q: What are the different types of aluminum sheets?

- There exists a variety of aluminum sheets, each possessing distinct characteristics and applications. Here are some commonly encountered types: 1. The plain aluminum sheet, with its smooth surface and uniform thickness, serves as the fundamental option. It holds widespread usage across various industries for general purposes. 2. The embossed aluminum sheet, achieved by rolling the metal through a patterned roller, presents a textured or patterned surface. It finds common application in fields like interior design or automotive trim, where decorative purposes are desired. 3. The perforated aluminum sheet, as its name implies, contains small holes or perforations throughout its surface. It frequently finds application in architectural scenarios, such as building facades or sunscreens, as well as in filtration systems. 4. The treadplate aluminum sheet, also known as checker plate or diamond plate, exhibits a raised pattern of lines or diamonds on its surface. This pattern enhances traction, making it suitable for industrial flooring or stair treads, where slip resistance is vital. 5. The anodized aluminum sheet undergoes an electrochemical process, forming a protective oxide layer on the surface. This process enhances durability, corrosion resistance, and allows for color customization through dye acceptance. Architectural applications, signage, and consumer products commonly employ anodized aluminum sheets. 6. The painted aluminum sheet, coated with a layer of paint, not only enhances appearance but also provides added corrosion protection. It is often utilized in applications where aesthetics are paramount, such as building facades, signage, or automotive parts. These examples represent a small selection of the aluminum sheet types available in the market. The selection of an appropriate type depends on specific project requirements, encompassing factors like durability, appearance, corrosion resistance, or slip resistance.

- Q: does aluminum sheet need to conduct ROHS detection?it's metel material, how much detections should it conduct for ROHS detection?

- it needs 4 CTI detections for ROHS.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

1050 1060 1070 3003 CC/DC Aluminum circles are used to make cookware/lighting/traffic signs

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords