4x8 Sheet Diamond Plate Aluminum

4x8 Sheet Diamond Plate Aluminum Related Searches

4x8 Sheet Aluminum Diamond Plate Aluminum Diamond Plate 4x8 Sheet Diamond Plate Aluminum Sheets 4X8 4x8 Aluminum Diamond Plate 4x8 Diamond Plate Aluminum Aluminum Diamond Plate 4x8 Diamond Plate Aluminum 4x8 4 X 8 Diamond Plate Aluminum 4 X 8 Aluminum Diamond Plate 4x8 1/8 Diamond Plate Aluminum 1 8 Aluminum Diamond Plate 4 X8 4x8 1 8 Aluminum Diamond Plate 4x8 1/4 Diamond Plate Aluminum 4x8 1/8 Aluminum Diamond Plate 4x8 1 4 Aluminum Diamond Plate 4X8 Sheet Aluminum 4 8 Aluminum Diamond Plate Black Aluminum Diamond Plate 4x8 4x8 1/4 Aluminum Diamond Plate 4x8 Aluminum Plate 4x8 Aluminum Diamond Plate 1/8 4x8 Aluminum Diamond Plate 1 8 1/4 Aluminum Diamond Plate 4x8 4x8 Aluminum Diamond Plate Price 4x8 3 16 Aluminum Diamond Plate 4x8 Diamond Plate Aluminum Price 1 8 Diamond Plate Aluminum Sheet Aluminum Plate 4x8 4 By 8 Aluminum Diamond Plate 1/8 Aluminum Diamond Plate 4'X8'4x8 Sheet Diamond Plate Aluminum Supplier & Manufacturer from China

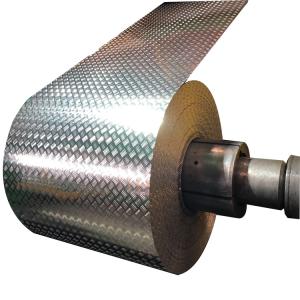

4x8 Sheet Diamond Plate Aluminum is a type of aluminum sheet with a diamond-shaped pattern on its surface, designed to provide slip resistance and durability. This product is made from high-quality aluminum, ensuring its strength and longevity in various applications. The diamond plate's unique design not only offers a non-slip surface but also adds an aesthetic appeal to the areas where it is installed.The 4x8 Sheet Diamond Plate Aluminum is widely used in a range of industries and applications, including construction, transportation, and manufacturing. It is commonly found in stair treads, flooring, ramps, and walkways, where slip resistance is crucial for safety. Additionally, its corrosion-resistant properties make it an ideal choice for marine and outdoor applications. The product's versatility also extends to decorative purposes, as it can be used to enhance the appearance of vehicles, walls, and other surfaces.

Okorder.com is a leading wholesale supplier of 4x8 Sheet Diamond Plate Aluminum, offering a vast inventory to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 4x8 Sheet Diamond Plate Aluminum they provide meets the highest standards. Their extensive stock allows customers to find the right size, thickness, and finish for their specific requirements, making Okorder.com a reliable source for this essential product.

Hot Products