4x8 Aluminum Sheets - Python Embossed Sheet for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Python Embossed Sheet for Auto Tool Case

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Python Embossed Sheet for Auto Tool Case

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Python Embossed Sheet for Auto Tool Case

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

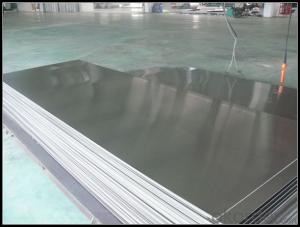

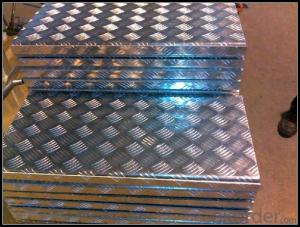

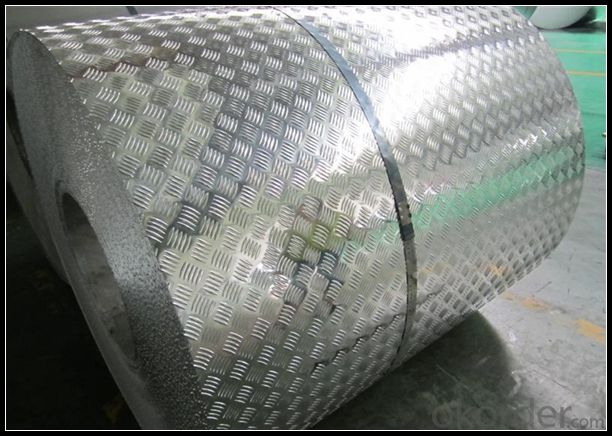

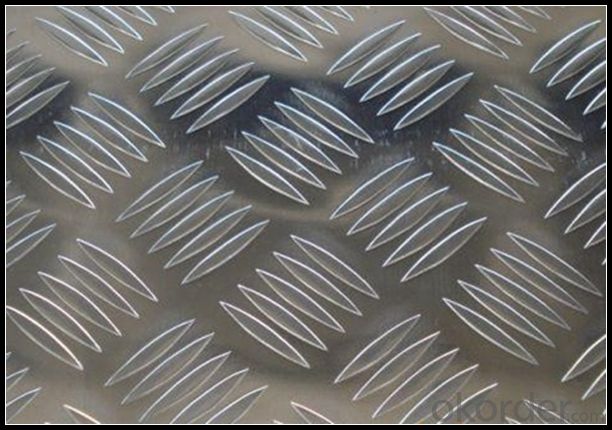

5. Image of Python Embossed Sheet for Auto Tool Case

6. Package and shipping of Python Embossed Sheet for Auto Tool Case

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on the alloy and temper of the material. However, in general, aluminum sheets have a relatively low impact strength compared to other metals. This is because aluminum is a lightweight material that is not as strong or durable as steel or other alloys. The impact strength of aluminum sheets is typically measured in terms of the energy required to cause the material to fracture or deform. This can be expressed in units such as joules or foot-pounds. While specific values may vary, aluminum sheets generally have an impact strength ranging from 10 to 40 joules or 7 to 30 foot-pounds. It is important to note that the impact strength can be influenced by factors such as thickness, surface condition, and the presence of any surface treatments or coatings. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific tests to determine the impact strength of a particular aluminum sheet.

- Q: Do 101 aluminum sheets have any specific insulation properties?

- 101 aluminum sheets do not possess any distinct insulation properties, as aluminum is an efficient conductor of both heat and electricity, failing to offer protection against temperature extremes. Nevertheless, these sheets can serve as reflective surfaces, effectively bouncing back heat or light. To achieve insulation, it is necessary to incorporate supplementary materials like foam or fiberglass in conjunction with the aluminum sheets.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Can aluminum sheets be used for battery casings?

- Yes, aluminum sheets can be used for battery casings. Aluminum is a commonly used material in the manufacturing of battery casings due to its lightweight, corrosion-resistant, and durable properties. It also allows for efficient heat dissipation, making it suitable for various types of batteries.

- Q: Can 101 aluminum sheets be bonded to other materials?

- Indeed, it is possible to bond 101 aluminum sheets with other materials. Aluminum demonstrates remarkable versatility in its capability to be bonded with a vast array of substrates through diverse bonding techniques. Several commonly employed methods for bonding aluminum sheets to other materials comprise adhesive bonding, mechanical fastening, welding, and brazing. The selection of a specific bonding technique hinges upon factors such as the composition of the material to be bonded with aluminum, the desired strength of the bond, and the intended application. Nonetheless, it is crucial to ensure compatibility between the aluminum sheets and the other materials to guarantee the establishment of a robust and long-lasting bond.

- Q: Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Indeed, 101 aluminum sheets prove to be fitting for the production of radiators. This particular aluminum alloy, known as 101 aluminum, boasts a pure composition that lends itself to exceptional thermal conductivity, making it a prime choice for radiator utilization. Moreover, its remarkable resistance to corrosion proves pivotal in radiator applications that frequently entail contact with water and other fluids. Furthermore, the lightweight nature and ease of manipulation of 101 aluminum sheets facilitate efficient processes for radiator manufacturing. In summary, the desired properties and characteristics essential for the creation of radiators are duly satisfied by 101 aluminum sheets.

- Q: Can aluminum sheets be used for architectural applications?

- Yes, aluminum sheets can be used for architectural applications. Aluminum is a versatile and lightweight material that offers excellent strength, durability, and corrosion resistance. It can be easily formed, shaped, and fabricated into various architectural elements such as façades, roofs, windows, doors, and cladding. Its aesthetic appeal, along with its ability to withstand harsh weather conditions, makes it a popular choice in contemporary architectural designs.

Send your message to us

4x8 Aluminum Sheets - Python Embossed Sheet for Auto Tool Case

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords