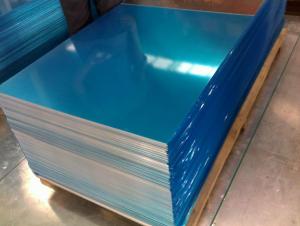

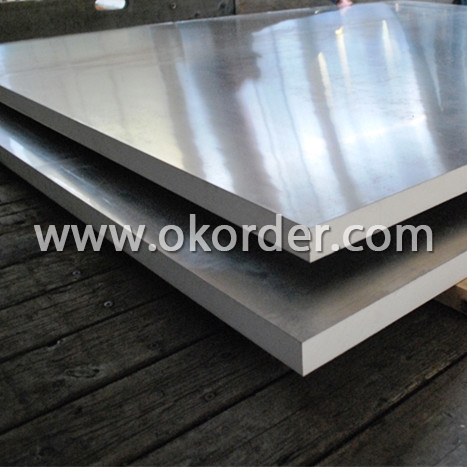

Hot Sale 4 X 8 Colored Aluminum Sheets 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Hot Sale Aluminum Plates 8XXX

|

Alloy Number |

AA8011 , AA8006 etc. |

|

Temper |

H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

|

Thickness |

0.1mm – 500mm |

|

Width |

10mm- 2200mm |

|

Standard |

GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications ofHot Sale Aluminum Plates 8XXX

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Hot Sale Aluminum Plates 8XXX

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Hot Sale Aluminum Plates 8XXX

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: Can aluminum sheets be soldered?

- No, aluminum sheets cannot be soldered using traditional soldering methods. However, alternative techniques such as specialized soldering alloys, fluxes, or adhesives can be used to join aluminum sheets together.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- put pans in sink boil some water with cream of tartar and pour on pans allow to soak as water cools scrub pans should take care of issues

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- You are not eating the aluminum foil when wrap food in it to cook. There is little transference of aluminum to the food you eat. When using it for baked potatoes, the skins just slide off so the potato meat itself had not contact with the foil. Though I have also read something on the use of aluminum cooking vessels and aluminum foil having some properties that can be dangerous to our health, I could find no articles from the FDA or other such qualified organizations regarding the use of aluminum foil.

- Q: What are the different methods of surface printing aluminum sheets?

- There are several different methods of surface printing aluminum sheets, each with its own advantages and applications. Some of the common methods include: 1. Screen Printing: This is a popular technique where a mesh screen with a stencil of the desired design is used. Ink is then forced through the open areas of the stencil onto the aluminum sheet. Screen printing allows for high precision and vibrant colors, making it suitable for various applications such as signage, labels, and decorative purposes. 2. Digital Printing: With advancements in technology, digital printing has become a popular method for printing on aluminum sheets. This method uses inkjet technology to directly print the design onto the surface of the sheet. Digital printing offers high detail and a wide range of colors, making it suitable for customized and complex designs. 3. Offset Printing: Offset printing is a versatile method often used for high-volume production. It involves transferring the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. This technique provides consistent and accurate printing results and is commonly used for packaging, labels, and large-scale printing. 4. Flexographic Printing: Flexographic printing is a cost-effective method commonly used for printing on flexible materials, including aluminum sheets. It involves using flexible relief plates with the desired design, which are then pressed onto the sheet. Flexographic printing is suitable for large-scale production and is often used for packaging materials and labels. 5. Gravure Printing: Gravure printing, also known as rotogravure printing, is a method that uses engraved cylinders to transfer ink onto the aluminum sheet. This technique is known for its high quality and ability to reproduce fine details. Gravure printing is commonly used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: While not technically a printing method, embossing is a popular technique used to create raised designs or patterns on aluminum sheets. This can be done through mechanical or heat processes, creating a three-dimensional effect. Embossed aluminum sheets are often used for decorative purposes, architectural applications, or to enhance the grip on surfaces. These are just some of the methods used for surface printing aluminum sheets. The choice of method depends on factors such as the desired design, level of detail, quantity, budget, and intended application.

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can indeed be an alternative to plastic in certain applications. Aluminum is a highly versatile and sustainable material that offers several advantages over plastic, such as being more durable, resistant to UV rays, and having a longer lifespan. Additionally, aluminum is recyclable and can be reused indefinitely, making it a more environmentally friendly choice. However, the suitability of aluminum sheets as an alternative to plastic would depend on the specific application and requirements.

- Q: What type of aluminium sheet is a food grade?

- You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is widely used in heat sink applications due to its excellent thermal conductivity and lightweight properties. It effectively dissipates heat generated by the LED, helping to maintain optimal operating temperatures and prolong the lifespan of the lighting system.

- Q: Are aluminum sheets suitable for boat building?

- Yes, aluminum sheets are suitable for boat building. Aluminum is a popular material choice for boat construction due to its numerous advantageous properties. Firstly, aluminum is lightweight, which makes it easier to handle and transport during the boat building process. This lightweight characteristic also contributes to better fuel efficiency and improved overall performance of the boat. Additionally, aluminum is highly resistant to corrosion, especially in saltwater environments, making it an ideal choice for boat building. This resistance to corrosion ensures that the boat remains durable and maintains its structural integrity for a longer period of time, even when exposed to harsh weather conditions. Furthermore, aluminum sheets offer excellent strength-to-weight ratio, providing a sturdy and reliable structure for the boat. This strength allows the boat to withstand the forces encountered while sailing, ensuring a safe and enjoyable experience for the occupants. Moreover, aluminum is a versatile material that can be easily molded and shaped into various boat designs. This flexibility allows for customization and the creation of unique boat designs that meet specific requirements and preferences. Lastly, aluminum is a sustainable and environmentally friendly material. It is fully recyclable, reducing the environmental impact of boat building and promoting a greener approach to marine construction. In conclusion, aluminum sheets are indeed suitable for boat building due to their lightweight nature, corrosion resistance, strength, versatility, and eco-friendliness.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sale 4 X 8 Colored Aluminum Sheets 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords