High quality 5083/5754/5052/5182/aluminum sheet for car wheels/doors/hoods

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automotive aluminum sheets refer to aluminum alloy sheets used in automobile manufacturing. Aluminum is widely used in modern automobile manufacturing due to its lightweight, high strength, corrosion resistance and other advantages. Automotive aluminum sheets usually use 1xxx, 3xxx, 5xxx and 6xxx alloys, such as: 1060, 1100, 3003, 3105, 5052, 5083, 5182, 5454, 6061, 6063, 6005 and other aluminum alloys.

Aluminum sheet for automobile specifications:

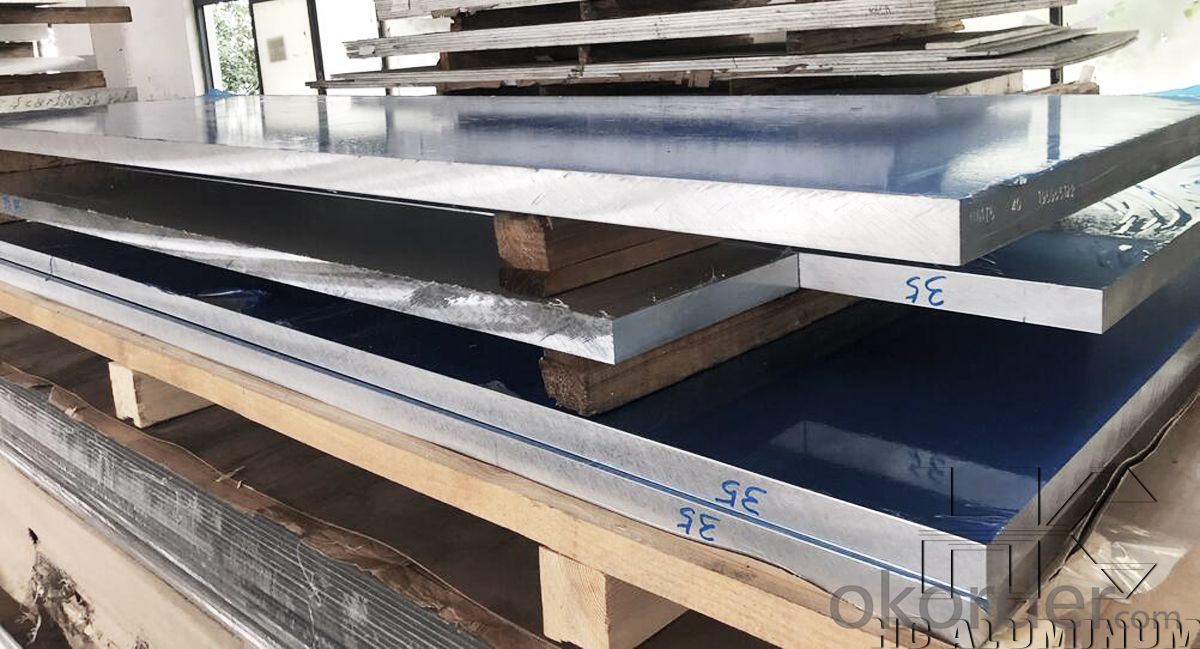

Aluminium Alloy | Thickness(mm) | Width(mm) | Temper |

A1050,A1060,A1070,A1100 | 0.2-8.0 | 20-2650 | O,H12,H14,H16,H18,H22,H24,H26 |

A3003,A3004,A3105 | 0.2-8.0 | 20-2650 | O,H12,H14,H16,H18,H22,H24,H26 |

A5052,A5005,A5083,A5754 | 0.2-8.0 | 20-2650 | O,H12,H14,H34,H32,H36,H111,H112 |

A6061,A6082,A6063 | 0.2-8.0 | 20-2650 | T4,T6,T651 |

Material process | CC AND DC | ||

Customerize size | Size can be produced as per clients requirement | ||

Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing Mirror,Brush,Perforated,Tread plate ,Corrugated etc | ||

Quality Standard | ASTM B209,EN573-1,etc | ||

MOQ per size | 1 ton and sample is available | ||

Payment Terms | TT,L/C, wire transfer, Western Union, etc. | ||

Delivery time | 25-35 working days after payment | ||

Material Quality | Tension levelled ,flat ,Free of defects like oil stain,Roll Marks,Waves,Dents scratches etc ,A+++ quality, production process passed sgs and bv inspection | ||

Application | Construction ,Building,Decoration ,Curtain Wall, Roofing, Mould, Lighting, curtain wall, Construction ,Building,Decoration ,Curtain Wall, Roofing, Mould, Lighting, curtain wall, ship building,Aircraft,Oil Tank ,Truck Body etc | ||

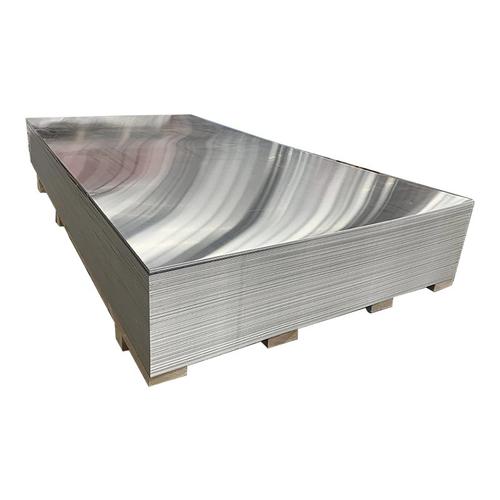

Packing | Standard export worthy wooden pallets and standard packing is about 2 tons/pallet Pallet weight also can be as per client's | ||

Chemical composition

Performance advantages of automotive aluminum sheets:

1. Lightweight: The density of aluminum is low, which helps reduce the weight of the car, improve fuel efficiency, and reduce carbon dioxide emissions.

2. High strength: Alloyed aluminum sheets have excellent strength and deformation resistance to meet the durability requirements of automobile structural parts.

3. Corrosion resistance: Aluminum alloy has better corrosion resistance than steel in humid and salt spray environments, and is suitable for exterior and chassis components.

4. Formability: Aluminum alloy has good ductility, making it easy to manufacture complex body shapes through a variety of processes to meet design requirements.

5. Recyclability: Aluminum is highly recyclable. The recycling process consumes low energy, reduces resource consumption, and improves sustainability.

6. Shock absorption and noise resistance: Aluminum alloy has better shock absorption performance than steel, which helps improve riding comfort.

7. Heat dissipation performance: Aluminum has good thermal conductivity and is suitable for components with high heat dissipation requirements.

8. Appearance and handling: The surface of the aluminum sheet is easy to handle, which improves the appearance and durability and meets the requirements of appearance and wear resistance.

The main applications of aluminum sheets in automobiles include:

1. Body outer panels: Aluminum alloy body panels are lighter, which helps reduce the weight of the car, improve fuel efficiency and reduce emissions, and also has good corrosion resistance.

2. Doors and hood: Aluminum alloy materials help reduce the weight of these parts while maintaining high strength and safety.

3. Chassis and structural parts: Aluminum alloy materials are often used in automobile chassis and other load-bearing parts to reduce vehicle weight and improve vehicle controllability.

4. Wheel hub and suspension system: The application of aluminum alloy in these components can effectively reduce the unsprung mass and improve the vehicle's handling performance and comfort.

FAQ:

Q1: How can I get your quotation?

A1: Please mention the alloy and condition, application, thickness, tensile strength, elongation, etc. and we will quote as soon as possible.

Q2: How about the delivery time?

A2: It usually takes about 7-35 days according to different order requirements.

Q3: Can we visit your factory?

A3: Of course, we sincerely welcome you to visit us at any time!

Q4: What is your product range?

A4: Our company's products include 1-8 series of aluminum foil, aluminum coils, aluminum sheets, aluminum discs, aluminum pattern sheets, etc.

Q5: What is the packaging?

A5: Our products are packed in wooden boxes for sea transportation

Q6: How about the delivery time?

A6: It usually takes about 7-35 days according to different order requirements.

Q7: What is the minimum order quantity?

A7: The minimum order quantity is 2 tons to 5 tons.

- Q: Can aluminum sheet be used for signage?

- Certainly! Aluminum sheet is a viable option for signage purposes. Its durability, versatility, and cost-effectiveness make it a popular choice among sign makers. Being a lightweight material, it is resistant to corrosion, making it suitable for both indoor and outdoor signage. With aluminum sheet, one can easily cut, shape, and form it into various sizes and designs, allowing for customizable signage options. Moreover, it is effortless to print or engrave upon, making it perfect for displaying text, graphics, and logos. Its sleek and professional appearance enhances its appeal for signage purposes. In conclusion, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- Aluminum in that form for cooking really isn't safe anymore. Use it for a planter. The only really safe Aluminum cookware is Anodized (hardened on the outside). They have found that with he softer forms of Aluminum you are actually getting it in your food - they think this could be a link to Alzheimer's Disease.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: 25mm thickness of hard aluminum processing to 6mm how to process, thank you all

- Oh, the 25mm thickness of the hard aluminum processing to 6mm, I suggest you contact the mill for rolling it.

- Q: We just bought a house with aluminum wiring and we knew about it in the inspection report, but everyone kept telling us it's no big deal. There was so much going on and I didn't look into it myself and now I just surfed the web on it and I am filled with anxiety! Please help! Did we make a huge mistake? How common are the dangers? Also, my insurance company didn't ask me about wiring, but some sites said that they don't cover aluminum wiring. Should I ask them? I am so overwhelmed and scared. I do not want a fire for my family!

- you will need to speak to an electrician, but the last i heard the wiring is not the problem, the problem is using things like outlets that are not rated for aluminum. copper in the outlet heats up where it joins the house wiring, and the house burns down. when aluminum first came out, some moron forgot to test for that, so there were a lot of a fires. people have mistakenly blamed the wiring. as long as you dont run to home depot and grab the cheapest outlet you see and say this is just as good . you will be fine.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: Can aluminum sheet be used for architectural façade systems?

- Yes, aluminum sheet can be used for architectural façade systems. Aluminum is a versatile material that offers durability, lightweight properties, and ease of installation, making it suitable for constructing attractive and functional façades in various architectural designs.

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Spray paint, often Enamel, is pretty tough by itself, but I see your concern about it abrading in your pocket or by continuous use. There's a couple of things you can do to help with the wear and tear. Firstly, painting on Aluminum is great. You'll have no adhesion problems with the paint, so long as the aluminum is not polished (mirror finished) If it is, you need to scratch it a bit in order to allow the paint something to grab on to. You can use the same stencil you will eventually paint with to apply an etching solution (Etch I-M) so you don't mess up the finish on other parts of the phone. Or you can sand it with 0000 steel wool (that's 4-aught steel wool...), which is really really fine sanding. If the aluminum is 'sanded' or 'brushed' then you're probably good to go, just make sure that there is not a clear coat on the aluminum. If there is, then do the etching or sanding to it as well to get that clear coat off. You want to paint directly onto the aluminum. Once you spray your stencil with the paint of your choice over the etched or prepared surface, you should have a very durable finish. However, since you want it to be uniformly Matt, I'd say that you should find a good, high quality Matt spray varnish or topcoat. Lacquer is good (Varathane, Deft) and durable, and importantly, youcan always throw on another clear coat if the wear and tear is getting to the design. One thing: DON'T RUSH THE PAINTING! Allow enough time for each coat to dry completely, and once finished, let the final clear coats dry absolutely perfectly before handling the phone too roughly. Do some of this and your phone will look great. hope that helped...

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

High quality 5083/5754/5052/5182/aluminum sheet for car wheels/doors/hoods

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords