6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Thick Plate for mold production

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Thick Plate for for Boat and Lighting:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

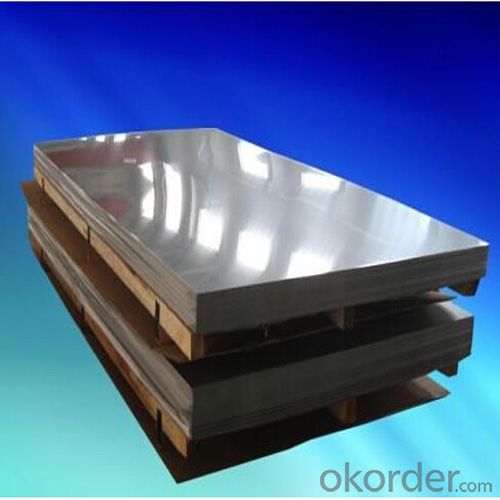

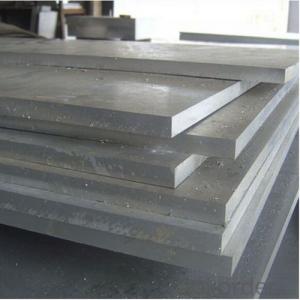

3. Aluminum Thick Plate Images:

4. Aluminum Thick Plate for for Boat and Lighting Specification:

Chemical Composition Limits for Aluminum Alloys

Composition in percent by weight according to The Aluminum Association. The values associates maximum limits unless shown as a range or a minumum.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others Each | Others Total | Al. Min. |

| 6061 | 0.40- 0.8 | 0.7 | 0.15- 0.40 | 0.15 | 0.8- 1.2 | 0.04- 0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

| 7075 | 0.40 | 0.50 | 1.2-2.0 | 0.30 | 2.1- 2.9 | 0.18- 0.28 | 5.1- 6.1 | 0.20 | 0.05 | 0.15 | Rem. |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.9 | 1.2- 1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Rem. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchanging experience with several quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes and video,we will be responsible.

- Q: Normally, when I install a 30-amp dryer receptacle, the wire is #10 copper and I double over the end with lineman's pliers prior to landing it in the lug just to be extra tight. Today I replaced a dryer outlet wired with #8 aluminum SE. The quandaray I have is that the lugs seem made for #6 and the #8 just sort of flattens and divides under the screw. Is this safe? The doubling over move makes the wire way too thick for the lugs to close. I've been doing electric for many years and have never run into this. Should I go back and re-run the circuit (only about 30 feet) in #10 copper? What is the actual draw of a typical electric dryer on high heat, anyway? Thanks.

- Run 30 feet of 10-3 with ground or take a chance of heating up the dryer's receptacle? HM MM! I sure wouldn't have a problem making this decision. If you decide to leave the aluminum wire, at least put some NOLOX on it.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Use gun bluing . It is the stuff they use on steel guns, it is kind of a dye. Got at a sports store that sells real guns.

- Q: Are aluminum sheets easy to work with?

- Yes, aluminum sheets are generally considered easy to work with due to their lightweight nature, flexibility, and malleability. They can be easily cut, bent, shaped, and drilled, making them versatile for various applications in industries such as construction, automotive, and manufacturing.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets, when compared to steel sheets, are significantly lighter in weight. This is because aluminum has a lower density than steel, making it a more lightweight and versatile material. The specific weight difference between aluminum and steel sheets will depend on the thickness and dimensions of the sheets. However, generally speaking, aluminum sheets can weigh about 1/3 less than steel sheets of the same size. This makes aluminum sheets an ideal choice in applications where weight is a critical factor, such as in the aerospace industry or for lightweight structures.

- Q: How do I clean and maintain aluminum sheets?

- In order to clean and maintain aluminum sheets, there are several steps that can be followed: 1. To begin, one should prepare a cleaning solution by combining warm water with a mild detergent or dish soap in a bucket or sink. It is important to avoid using harsh chemicals or abrasive cleaners as they can cause damage to the aluminum. 2. Next, immerse a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. It is necessary to ensure that the entire surface is covered, with special attention given to any stains or dirt build-up. 3. In the case of stubborn stains or grime, a non-abrasive brush or toothbrush can be used to scrub the affected areas. However, caution should be exercised to prevent applying excessive pressure, as this may result in scratching the aluminum. 4. Following the cleaning process, the sheets should be thoroughly rinsed with clean water to eliminate any residue from the cleaning solution. It is important to ensure that all soap is completely rinsed off. 5. Once rinsed, a clean and dry cloth should be used to remove any excess water and dry the aluminum sheets. This step aids in preventing water spots or stains from forming. 6. To preserve the shine and condition of the aluminum, a thin layer of aluminum polish or wax can be applied. It is advisable to follow the manufacturer's instructions for the best outcomes. 7. Regular inspection of the aluminum sheets is recommended to detect any signs of damage, such as dents, scratches, or corrosion. If any issues are noticed, they should be promptly addressed to prevent further harm. It is crucial to handle aluminum sheets with care to avoid damage. The use of abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface should be avoided. Regular cleaning and maintenance will assist in preserving the appearance and prolonging the lifespan of the aluminum sheets.

- Q: I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- This Site Might Help You. RE: Aluminum advantages and disadvantages....? I have a project on the aluminum element. What are the advantages and disadvantages of this element?...What are the risks/dangers?...Thank you so much ---And please tell me where I could find this information too.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a lightweight and durable material, making it suitable for fencing purposes. It is resistant to rust and corrosion, making it a long-lasting option. Additionally, aluminum sheets offer a sleek and modern look to any fence.

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- Which is better? Neither, they are different though. Steel is a very good material for cost effective bicycles 1. If properly designed it can be made light 2. It usually has a forgiving ride. A steel bike will absorb some the shock from the road. Over a longer ride this is very nice indeed. This is what is meant by the phrase Steel is real!. 3. It is a very thoroughly understood material, so designs are very reliable 4. Unfortunately it is prone to rust. Keep the paint in good shape and if you have a nicer bike use JP Weigle Frame Saver on the inside of any tubes you can. Should do the trick. 5. Can be worked with easily available tools whereas aluminum requires some specialized and expensive tools. This is why many custom bikes are made from steel. Aluminum: 1. Light, stiff, efficient 2. Can be a harsh ride. 3. Good for entry level racers who can't afford Carbon Fiber (CF) 4. Cost effective 5. Very rust resistant It comes down to money and preference. I personally have voted steel a long time ago. I've ridden many aluminum bikes and don't like the ride. But that's me. Try them yourself and see which you like best. As far as longevity, that's more of a design issue than material.

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- I'd at least double it, if not triple it in thickness for cooking ribs. Single ply regular aluminum foil won't give you the result you're looking for.

Send your message to us

6061 Aluminum Thick Plate for mold production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords