4 X 8 Aluminum Diamond Plate Sheets AA5052 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Sheets AA5052 Used for Constrcution Description

Aluminum Sheets AA5052 Used for Constrcution has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA5052 Used for Constrcution is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA5052 Used for Constrcution

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

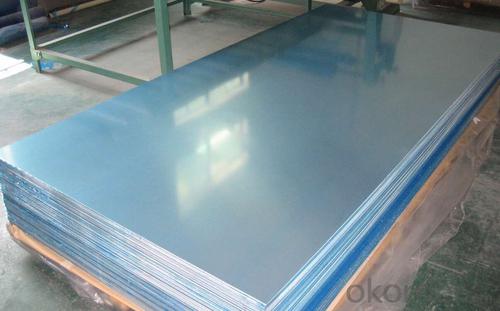

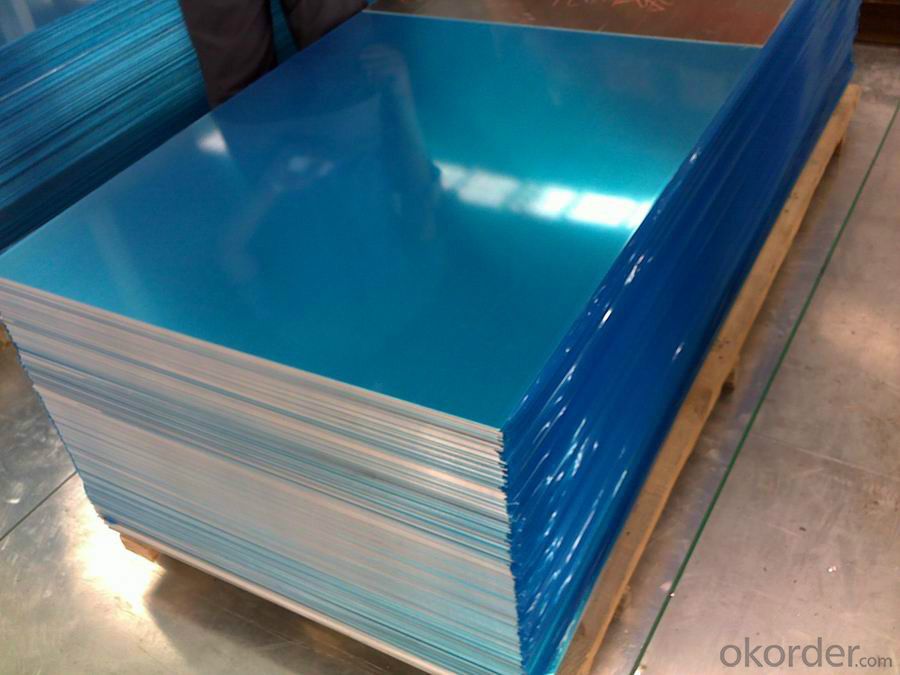

3.Aluminum Sheets AA5052 Used for Constrcution Images

4.Aluminum Sheets AA5052 Used for Constrcution Specification

Alloy | AA5052 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA5052 Used for Constrcution

A.What is the quality standard?

---Usually our standard is GB3880-2006

B. What is the largest width?

---It is 2300mm

C. What is the MOQ?

---Usually we can accept 80 tons.

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- Aluminum is a good choice if you plan on using it to grind more than just coffee. Plastic tends to soak up flavors due to oils in coffee, herbs and spices. So if you plan on multitasking metal is the way to go.

- Q: What are the different methods of forming aluminum sheets?

- Aluminum sheets can be formed using various methods, each with its own set of advantages and applications. Below are some examples of these methods: 1. Rolling: The most commonly used method for forming aluminum sheets is rolling. This involves passing a large aluminum ingot through a series of rolling mills, gradually reducing its thickness and increasing its length. The ingot is rolled multiple times until the desired thickness is achieved. Rolling is versatile, as it can produce aluminum sheets of different thicknesses and widths to suit various applications. 2. Extrusion: Another method used for forming aluminum sheets, particularly for complex cross-sectional profiles, is extrusion. In this process, a heated aluminum billet is forced through a shaped die, resulting in a continuous length of aluminum with the desired shape. Extrusion allows for the creation of intricate designs and is commonly employed in the production of structural components and frames. 3. Casting: Casting is a method used to form aluminum sheets with a specific shape or pattern. Molten aluminum is poured into a mold and left to cool and solidify. The mold can be made of different materials, depending on the complexity of the desired shape. Casting is often used for decorative purposes and in the production of architectural panels. 4. Stretch forming: Stretch forming is a specialized method used to form aluminum sheets into curved or contoured shapes. The sheet is clamped at its edges and stretched over a form using hydraulic or mechanical forces. As the sheet is stretched, it takes on the shape of the form, resulting in a curved or contoured sheet. Stretch forming is commonly utilized in the aerospace and automotive industries for components like fuselage sections and car body panels. 5. Pressing: Pressing, also known as stamping or punching, is a method employed to form aluminum sheets into specific shapes or patterns. The sheet is positioned between a die and a punch, and pressure is applied to deform the sheet. The die and punch can have various designs, allowing for the creation of simple cutouts or intricate patterns. Pressing is frequently employed in the manufacturing of automotive parts, appliances, and electronic enclosures. These are just a few examples of the various methods used to form aluminum sheets. Each method offers distinct advantages and is chosen based on the specific requirements of the desired shape, thickness, and application of the aluminum sheet.

- Q: Which is better, a water bottle made out of steel or one made out of aluminum?

- Unless okorder / A lightweight Nalgene BPA free water bottle

- Q: Can aluminum sheets be used for reflective purposes?

- Yes, aluminum sheets can be used for reflective purposes. Aluminum is a highly reflective metal that has a shiny and smooth surface. It has a high reflectivity index, making it an excellent material for reflecting light and heat. Aluminum sheets are commonly used for various reflective applications, such as in mirrors, solar panels, lighting fixtures, and insulation. Due to its reflective properties, aluminum sheets are also used in the construction industry to increase energy efficiency by reflecting sunlight and reducing heat absorption.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- Three 3000 series aluminum representing 30033003 3A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 series, is a commonly used alloy series.Four 4000 series aluminum on behalf of the 4A01 4000 series aluminum plate belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceFive series of 5000 representative 5052.5005.5083.5A05.5000 series is a commonly used aluminum alloy aluminum series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of the other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing of aluminum oxidation. More mature system in our country in 5000 series aluminum one.Six series of 6000 representatives of 6061 mainly contains two elements of magnesium and silicon, so the advantages of 4000 series and 5000 Series 6061 is a cold forging processing of aluminum products, suitable for applications in corrosion resistance, oxidation resistance requirement. Use good interface features excellent, easy coating, processing is good. Can be used for low pressure weapons and aircraft joints.

- Q: Can aluminum sheets be used for cladding?

- Yes, aluminum sheets can be used for cladding purposes. Aluminum is a popular choice for cladding due to its lightweight, durability, and corrosion resistance, making it suitable for both interior and exterior applications.

- Q: Can the aluminum sheets be used for manufacturing electrical conductors?

- Yes, aluminum sheets can be used for manufacturing electrical conductors. Aluminum is a highly conductive material and is frequently used in the electrical industry for making wires and cables.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Indeed, aircraft manufacturing finds aluminum sheets to be highly suitable. The aerospace industry extensively utilizes aluminum owing to its exceptional blend of qualities, encompassing its lightweight nature, robust strength, ability to withstand corrosion, and outstanding malleability. Such attributes render aluminum an optimal substance for constructing diverse aircraft elements, including fuselages, wings, and structural components. Furthermore, aluminum alloys can be effortlessly fused, facilitating efficient manufacturing procedures. In totality, aluminum sheets assume a pivotal function in aircraft manufacturing, substantially enhancing the aircraft's overall performance, durability, and safety.

- Q: Is it possible to use aluminum sheets as a material for exterior siding or cladding on buildings?

- <p>Yes, aluminum sheets are commonly used for siding or cladding due to their durability, lightweight, and resistance to corrosion. They are low maintenance, can be easily shaped, and come in various colors and finishes. Aluminum's resistance to weathering and its ability to withstand temperature extremes make it a popular choice for both residential and commercial buildings.</p>

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can be used in the construction industry. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various construction applications such as roofing, cladding, windows, and doors.

Send your message to us

4 X 8 Aluminum Diamond Plate Sheets AA5052 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords