Aluminum Sheet Embossed Aluminum Sheet Coated Aluminum Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

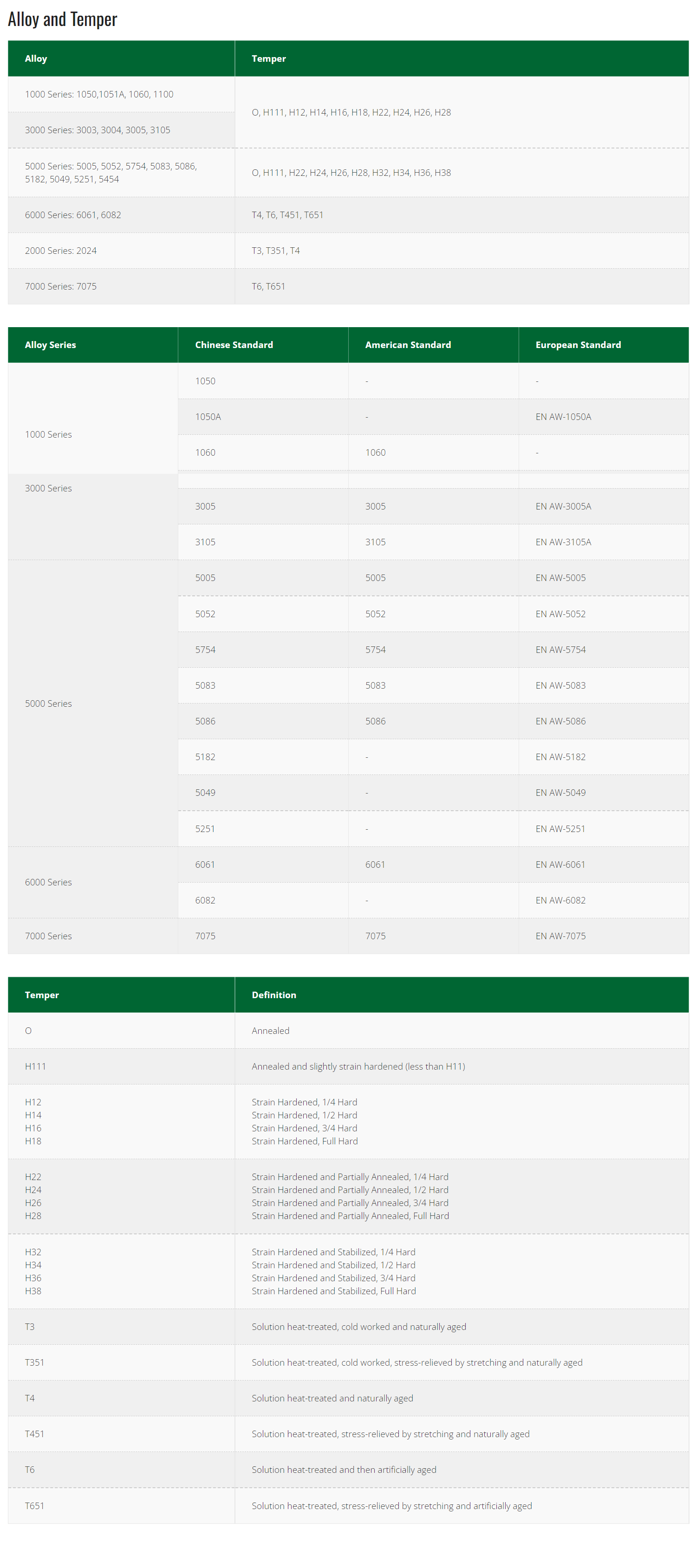

Specification

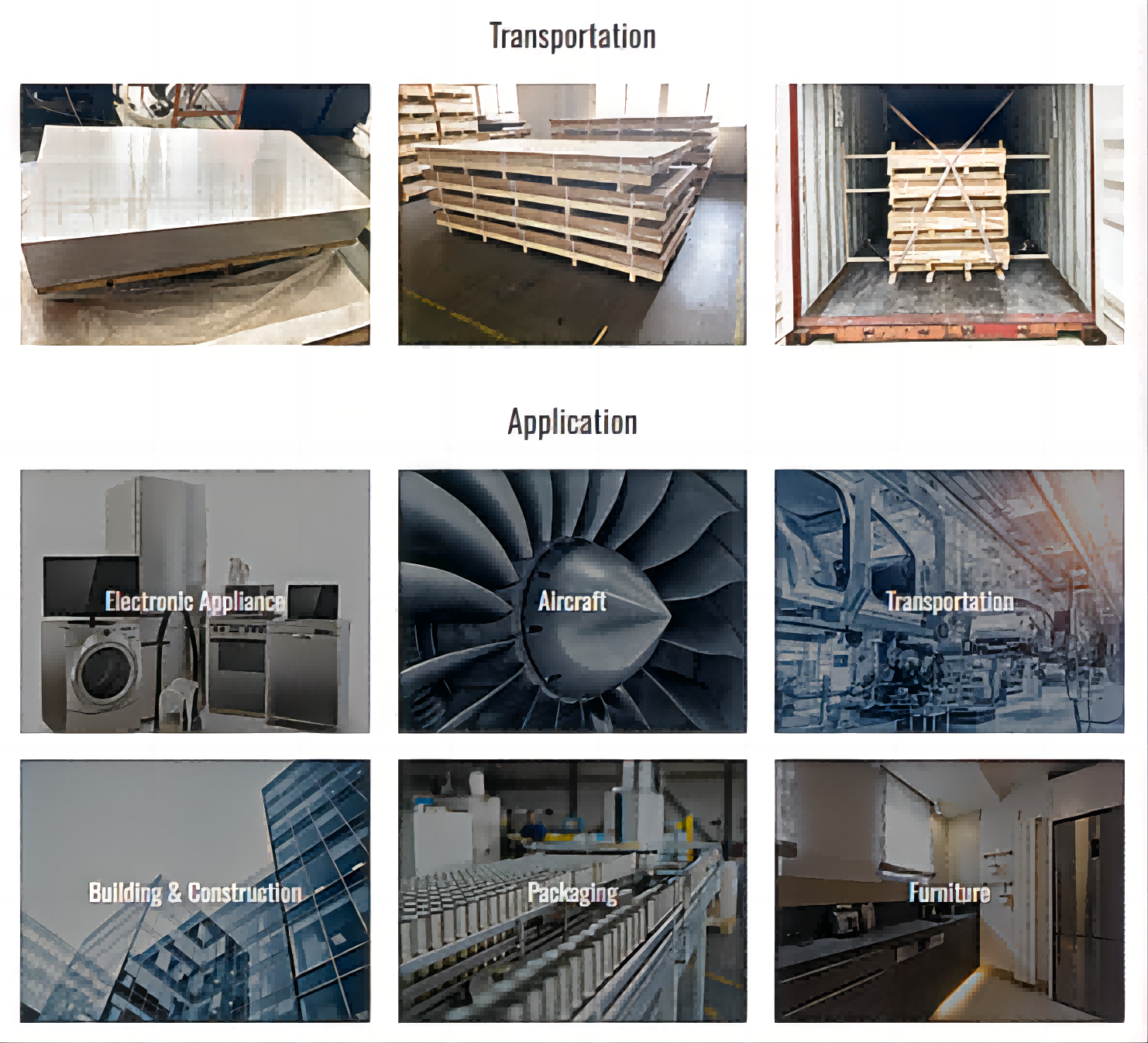

Aluminium sheets come in a wide range of grades and thicknesses, offering solutions for different needs. Whether in standard sizes or custom

specifications, aluminium sheets are produced with strict manufacturing processes to ensure stable quality and reliable performance.

With its outstanding properties and versatility, aluminium sheet is a preferred material choice across numerous sectors.

Advantages:

Lightweight: Aluminium sheets are significantly lighter than many other metals, making them ideal for applications where weight reduction is crucial.

Corrosion Resistance: Aluminium naturally forms a protective oxide layer, which enhances its resistance to corrosion, particularly in harsh environments.

High Strength-to-Weight Ratio: This property allows for the creation of strong yet lightweight components, beneficial in industries like aerospace and automotive.

Malleability: Aluminium sheets can be easily formed into complex shapes, allowing for diverse design possibilities.

Thermal Conductivity: Aluminium is an excellent conductor of heat, making it suitable for applications like heat sinks and thermal management systems.

Recyclability: Aluminium is fully recyclable, making it an environmentally friendly material choice. Recycled aluminium retains its original properties, supporting sustainable practices.

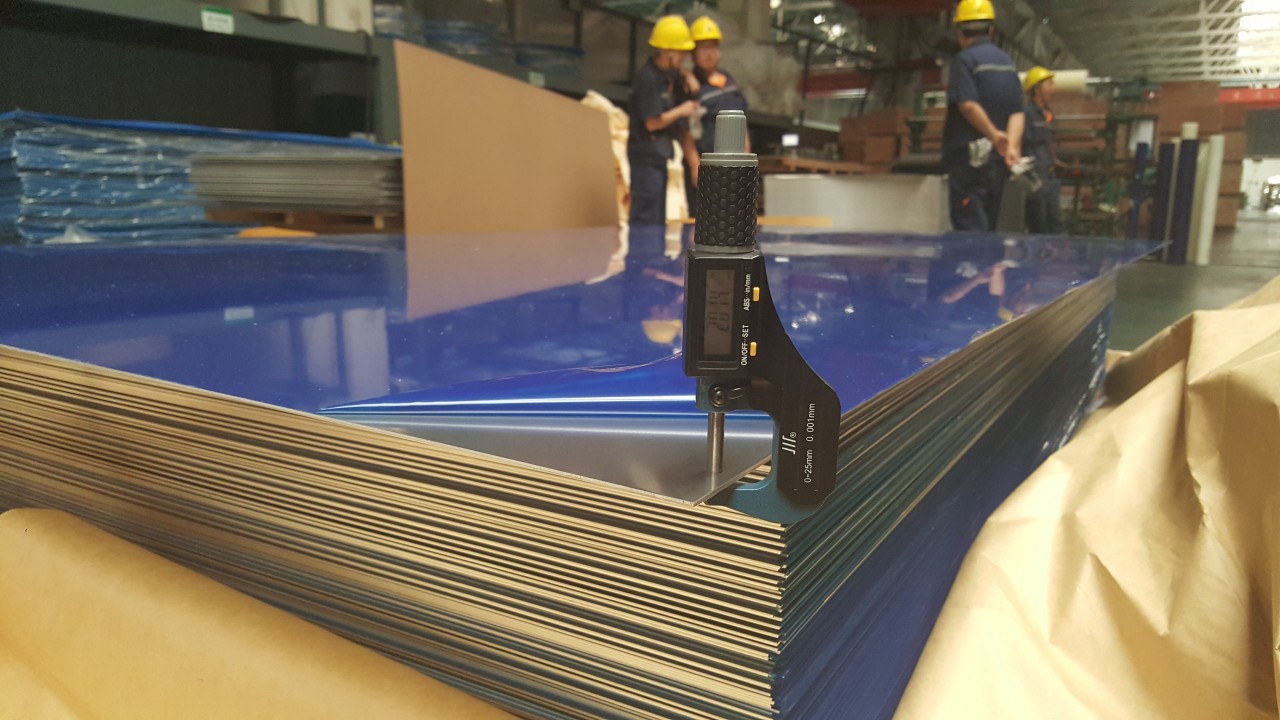

Images:

Maintenance and Care:

Cleaning: Regular cleaning with mild detergent and water can maintain the appearance and prevent build-up of contaminants.

Protection: For enhanced durability, consider applying protective coatings such as anodizing or painting.

Inspection: Periodic inspection for signs of wear, corrosion, or damage ensures long-term performance and safety.

Handling: Proper handling during transport and installation prevents dents, scratches, and other damage.

FAQ:

1. what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2.What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3.Can we supply samples?

Yes, we can!

4.What can you do if you have other quastions?

You can contact us freely at any time!

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a material for exterior walls in construction.

- <p>Aluminum sheets for exterior walls offer several advantages, including durability, low maintenance, and resistance to corrosion and weathering. They are lightweight, which can reduce the load on structures, and are recyclable, contributing to sustainability. Additionally, aluminum sheets can be easily shaped and painted, offering design flexibility. However, they have some disadvantages, such as being a poor insulator, which may require additional insulation for energy efficiency. They can also dent or scratch easily and may require more frequent replacement due to their lower resistance to impacts compared to materials like stone or brick. Furthermore, while they reflect heat well, they can also conduct cold, potentially leading to issues in extreme temperature conditions.</p>

- Q: What are the different methods of surface finishing for aluminum sheet?

- Aluminum sheets can undergo various surface finishing methods, each with its own distinct characteristics and advantages. Some commonly used methods include anodizing, painting, powder coating, polishing, and brushing. Anodizing is a widely employed technique that forms a protective oxide layer on the aluminum's surface. This process not only enhances the sheet's appearance but also improves its resistance to corrosion and durability. Anodized aluminum sheets are available in different colors and finishes, making them suitable for diverse applications. Painting is another frequently used method where a layer of paint is applied to the aluminum sheet to provide both decorative and protective coating. This approach allows for a wide range of colors and finishes, enabling customization and design versatility. Moreover, painting can enhance the sheet's resistance to weathering and scratches. Powder coating involves applying a dry, powdered coating to the aluminum sheet, which is then heated to create a durable and uniform layer. This technique offers excellent protection against corrosion, chemicals, and UV rays, making it ideal for applications requiring high durability and weather resistance. Polishing is a surface finishing method that employs abrasive materials to create a smooth and shiny surface on the aluminum sheet. This technique is commonly used to enhance the sheet's aesthetic appeal by eliminating imperfections and scratches. Polished aluminum sheets are often used in decorative applications where a reflective and lustrous surface is desired. Brushing is a process that gives the aluminum sheet a textured surface using abrasive brushes or pads. This method creates parallel lines or patterns on the sheet, resulting in a distinctive and attractive appearance. Brushed aluminum sheets find applications in architectural and interior design, as well as in the manufacturing of household appliances and automotive components. In conclusion, the various surface finishing methods for aluminum sheets offer a range of options to enhance their appearance, durability, and functionality. Whether it is anodizing, painting, powder coating, polishing, or brushing, each method brings unique benefits that can be tailored to specific applications and design requirements.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and durable material that has excellent corrosion resistance properties, making it suitable for ventilation applications. It can be easily formed and fabricated into various shapes and sizes, allowing for the customization of ventilation components. Additionally, aluminum is a good conductor of heat, which can be beneficial for HVAC systems that require efficient heat transfer.

- Q: Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Material details1 and 5052 aluminum magnesium alloy aluminum plate: 5052 aluminum plate belongs to the aluminum magnesium alloy aluminum plate, the use scope is widespread, especially in the construction industry cannot leave the alloy aluminum plate, also is the most promising aluminum alloy plate. The main alloy element of 5052 aluminum plate is magnesium, which has good corrosion resistance, good weldability, cold workability and medium strength.5052 aluminum plate is commonly used in the manufacture of aircraft and car fuel tanks, oil pipes, as well as traffic vehicles, ships sheet metal parts, instruments, street lamps, brackets and rivets, hardware, electrical appliances, such as shell.2 and 5005 aluminum magnesium alloy aluminum plate: 5005 aluminum plate, band strength and 3003, welding resistance, good processing, 5005 aluminum plate and 3003 alloy similar, with moderate strength and good corrosion resistance. The anodic oxide film is more bright than the oxide film on the 3003 alloy and is in harmony with the tone of the 6063 alloy.5005 aluminum plate is often used as conductor, cooker, instrument panel, shell and building decoration, building materials, internal and external materials, vehicle materials and so on.3 and 5754 aluminum magnesium alloy aluminum sheet: 5754 aluminum alloy has the characteristics of moderate strength, good corrosion resistance, weldability and easy processing and forming. It is a typical alloy in Al Mg alloy. In foreign countries, 5754 Aluminum Alloy plates of different heat treatment condition is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry.5754 aluminum is widely used in welding structure, storage tank, pressure vessel, ship structure and marine facilities, transport tanks as well as for the requirements of good processability, excellent corrosion resistance, high fatigue strength, high solderability and moderate intensity static situations.

- Q: Can aluminum sheets be used for structural purposes?

- Indeed, structural purposes can be fulfilled by utilizing aluminum sheets. This material, known for its lightness and remarkable malleability, can be effortlessly shaped and sized in diverse forms. Thanks to its exceptional strength-to-weight ratio, it is an ideal choice for structural applications that prioritize weight reduction. In industries such as aerospace, automotive, and construction, aluminum sheets are commonly employed to create structural components like panels, beams, and frames. Moreover, the corrosion resistance of aluminum adds to its suitability for structural purposes, particularly in outdoor or marine settings. Ultimately, aluminum sheets present a dependable and economical solution for structural applications.

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Strength-to-weight ratio.

- Q: This question asks about the various types of aluminum foil used specifically for the purpose of food packaging.

- <p>Aluminum foil used for food packaging comes in several types, each with specific applications: 1. Heavy-duty foil: Strong and durable, used for roasting meats and baking. 2. Light-duty foil: Thinner and more flexible, ideal for lining baking sheets and wrapping foods. 3. Reynolds Wrap: A brand known for its non-stick and heavy-duty aluminum foils, suitable for a wide range of cooking and baking needs. 4. Aluminum foil rolls: Available in various widths, used for general food wrapping and sealing. 5. Pre-cut aluminum foil squares: Convenient for individual food portions and small wrapping tasks. Each type offers different levels of heat resistance, malleability, and non-stick properties, catering to diverse food packaging requirements.</p>

Send your message to us

Aluminum Sheet Embossed Aluminum Sheet Coated Aluminum Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords