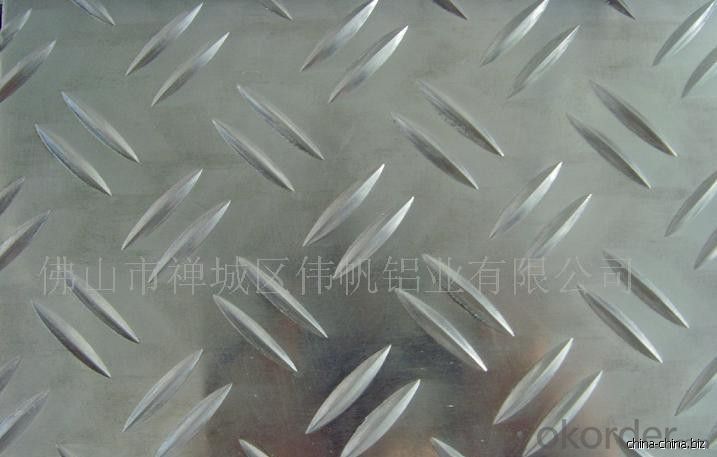

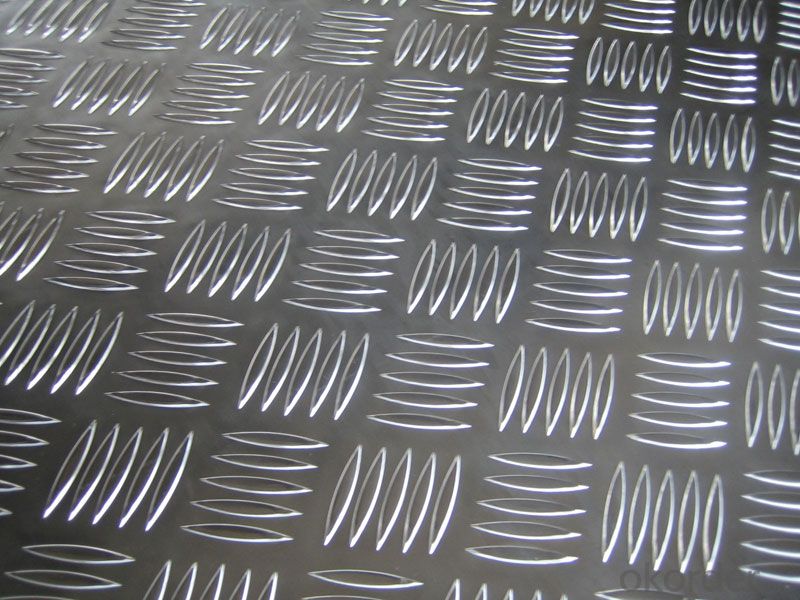

4x8 Embossed Aluminum Tread Plate Sheets for Bus Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications:

aluminum tread plate

1.Usage: using in bus, cars and shipping vessel as the floor.

2. Alloy: AA1050, AA1060, AA1070, AA3003

aluminum tread plate

1.Features:

1) Alloy: AA1050, AA1060, AA1070, AA3003

2) Temper: H14, H16, H18, H24, H26, H28, H34, H36, H38

3) Thickness: 1.20mm - 5.00mm

4) Width: 1000 ~ 1250mm

5) Length of sheet: 1000mm ~ 4000mm

2.Packing:

Covering with plastic film and brown paper and then packed with wooden package, directly loading into container for transshipment.

- Q: do recycling centers take already compacted aluminum cans? Link is below. if not then why are so many people making homemade can crushers?

- Aluminium is one of the most and best recyclable material. I'm sure they do.

- Q: Can aluminum sheets be used in aerospace industries?

- Aluminum sheets find frequent usage in aerospace industries. Lightweight and resistant to corrosion, aluminum proves to be an exceptional material with a remarkable strength-to-weight ratio, making it well-suited for diverse aerospace applications. Its capability to withstand elevated stress and pressure renders it valuable in the construction of aircraft structures, including wings, fuselage, and landing gear. Moreover, aluminum sheets possess malleability, allowing for the creation of intricate shapes that contribute to the requisite design flexibility within the aerospace sector. However, it is worth noting that aluminum alloys, rather than pure aluminum, are typically employed in aerospace applications due to their augmented mechanical properties and superior performance.

- Q: What are the different methods of surface finishing for aluminum sheets?

- There are several methods of surface finishing for aluminum sheets, each with its own advantages and applications. Some of the common methods include: 1. Anodizing: This process involves immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. Anodizing provides excellent corrosion resistance, durability, and can be colored or dyed for aesthetic purposes. 2. Polishing: Polishing is a mechanical process that involves buffing the aluminum sheet to create a smooth and reflective surface. It is commonly used for decorative applications and to enhance the appearance of the metal. 3. Brushing: Brushing involves using abrasive materials or brushes to create a directional grain pattern on the aluminum sheet's surface. This method is often used for architectural applications or to achieve a distinctive textured finish. 4. Powder coating: Powder coating involves applying a dry powder paint to the aluminum sheet's surface and then curing it under heat. This process provides a durable and vibrant finish, offering excellent resistance to weathering, chemicals, and UV rays. 5. Chemical etching: Chemical etching involves using acidic or alkaline solutions to selectively remove the aluminum from the sheet's surface, creating a textured or patterned design. This method is commonly used for decorative purposes or to enhance adhesion for subsequent coatings. 6. Laminating: Laminating involves bonding a protective film or layer onto the aluminum sheet's surface. This method provides added protection against scratches, stains, and other physical damage while also allowing for customization through different film finishes. 7. Sandblasting: Sandblasting uses high-pressure air or water to propel abrasive particles onto the aluminum sheet's surface, creating a textured or matte finish. It is often used to remove impurities, improve paint adhesion, or create a distinctive appearance. These are just a few of the many methods available for surface finishing aluminum sheets. The choice of method depends on the desired appearance, functionality, and specific requirements of the application.

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- Aluminium foil is manufactured to be of 'food grade' (i.e. safe to be used around food). It heats and insulates. It would never react with the food contained on/in it. Unless you're boiling your tomatoes in Sulphuric Acid of course! :-P

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks. Aluminum, especially 101 aluminum, is not resistant to many chemicals and can react with them, leading to corrosion and potential leakage. Chemical storage tanks require materials that are specifically designed to withstand the corrosive nature of chemicals, such as stainless steel or certain types of plastics. It is essential to use materials that are chemically resistant and can ensure the safety and integrity of the stored chemicals.

- Q: Are aluminum sheets non-magnetic?

- No, aluminum sheets are not magnetic.

- Q: Are aluminum sheets suitable for hydraulic applications?

- Indeed, aluminum sheets prove to be fitting for hydraulic applications. Being both lightweight and resistant to corrosion, aluminum serves as a remarkable option for hydraulic systems. Its commendable thermal conductivity aids in effectively dispersing heat produced during hydraulic operations. Furthermore, aluminum sheets can be effortlessly shaped and machined to fulfill precise design needs, rendering them adaptable for an array of hydraulic components including reservoirs, tanks, and piping systems. Nevertheless, it is crucial to bear in mind the pressure and temperature prerequisites of the hydraulic application, given that aluminum possesses inferior strength and melting point in comparison to metals like steel.

- Q: Is it possible to utilize a custom-made door in place of a standard door within a construction or renovation project?

- <p>Yes, you can use a custom-made door to replace a standard door in your project. However, it's important to ensure that the custom door meets all the necessary building codes and specifications required for your project. This includes considerations for size, material, fire resistance, insulation, and any other relevant standards. Additionally, you should consult with your architect or contractor to confirm that the custom door will fit properly within the existing framework and align with the overall design and functionality of the space.</p>

- Q: What are the different methods of surface passivation for aluminum sheets?

- There are several methods of surface passivation for aluminum sheets, including anodizing, chromate conversion coating, and organic coatings. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Chromate conversion coating is a chemical treatment that converts the aluminum surface into a thin chromate film, providing corrosion resistance. Organic coatings, such as paints or lacquers, can also be applied to aluminum sheets to provide a protective barrier against moisture and other environmental elements.

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

Send your message to us

4x8 Embossed Aluminum Tread Plate Sheets for Bus Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords