4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

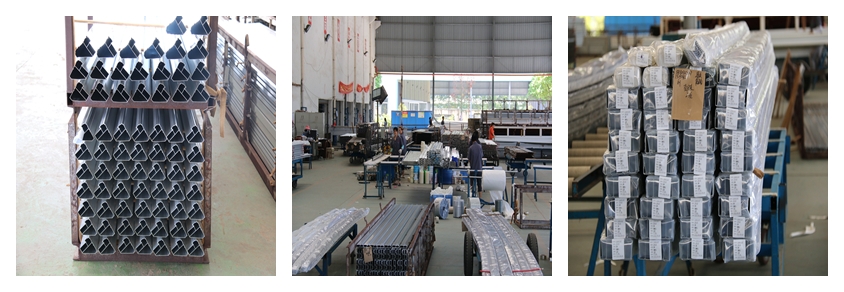

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What are the different joining methods for aluminum sheets?

- Aluminum sheets can be joined using various methods, each with its own advantages and considerations. Common techniques for joining aluminum sheets include: 1. Welding: Aluminum sheets can be welded together by melting them and using a filler material. Welding techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding are commonly used. Welding creates strong and durable joints, but it requires skilled labor and can be time-consuming. 2. Adhesive bonding: Another method is adhesive bonding, where a specialized adhesive or glue is applied to the surfaces to be joined. Adhesive bonding offers benefits like excellent corrosion resistance, uniform stress distribution, and the ability to join different materials. However, it requires proper surface preparation and can be affected by temperature and humidity. 3. Mechanical fastening: Mechanical fastening involves using bolts, screws, rivets, or clips to join aluminum sheets. It is a simple and cost-effective method that allows for easy disassembly if needed. However, it may create stress concentrations around the fasteners and the joints may not be as strong as welded ones. 4. Friction stir welding: Friction stir welding is a newer method gaining popularity for aluminum sheets. It involves rotating a non-consumable tool along the joint line, generating friction and heat that softens and joins the sheets. Friction stir welding offers benefits like high joint strength, low distortion, and defect-free welds. However, it requires specialized equipment and is limited to certain sheet thicknesses. 5. Clinching: Clinching is a cold joining method that deforms the sheets using a punch and die without melting them. The sheets are pressed together under high pressure, creating a mechanical interlock. Clinching is a fast and cost-effective method that doesn't require additional materials, but it may cause visible surface deformation. When choosing a joining method for aluminum sheets, factors like joint strength, corrosion resistance, aesthetics, production cost, and specific application requirements should be considered. Each method has its own advantages and limitations, so the most suitable technique depends on the project's specific needs.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Yes, aluminum sheets can be used for manufacturing chemical piping systems.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: Are aluminum sheets suitable for industrial machinery?

- Yes, aluminum sheets are suitable for industrial machinery. Aluminum is a versatile and widely used material in various industries, including machinery and manufacturing. Aluminum sheets offer several advantages that make them suitable for use in industrial machinery. Firstly, aluminum sheets are lightweight. Compared to other metals like steel, aluminum has a significantly lower density, making it ideal for applications where weight reduction is important. The lightweight nature of aluminum allows for easier handling, transportation, and installation of machinery components, resulting in higher efficiency and lower costs. Secondly, aluminum sheets are highly corrosion resistant. Aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This resistance to corrosion makes aluminum sheets suitable for use in industrial machinery, especially in environments where exposure to moisture, chemicals, or harsh weather conditions is common. Additionally, aluminum sheets have excellent thermal conductivity. This property allows aluminum to quickly and efficiently dissipate heat, making it suitable for applications where machinery components generate significant heat. By effectively managing heat, aluminum sheets help prevent overheating and prolong the lifespan of machinery. Furthermore, aluminum sheets are easily formable and can be fabricated into various shapes and sizes, making them adaptable to different machinery designs and requirements. They can be easily machined, welded, and joined, allowing for easy integration into industrial machinery manufacturing processes. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, reducing the environmental impact of industrial machinery production and disposal. In conclusion, aluminum sheets are suitable for industrial machinery due to their lightweight nature, corrosion resistance, thermal conductivity, formability, and sustainability. These qualities make aluminum sheets an excellent choice for various applications in the machinery and manufacturing industries.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can be used in the construction industry. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various construction applications such as roofing, cladding, windows, and doors.

- Q: What is the density of aluminum sheets?

- The density of aluminum sheets is subject to variation based on the particular alloy and thickness of the sheet. On average, aluminum sheets have a density ranging from 2.6 to 2.8 grams per cubic centimeter (g/cm³). It is worth mentioning that this figure may undergo slight modifications as a result of the precise manufacturing process and any additional coatings or treatments administered to the sheets.

- Q: What is a composite aluminum plate?

- The aluminum plastic composite plate is a composite material made of chemically treated coated aluminium plate as surface material, polyethylene plastic as core material, and manufactured on special aluminum plate production equipment.The unique properties of aluminum-plastic composite board itself has decided, its wide application: it can be used for building exterior wall, curtain wall, old building renovation, interior walls and ceiling decoration, advertising signs, display rack, dust purification engineering. The utility model belongs to a new type of building decoration material.APCP (also called APCP) as a new type of decorative materials, since the last century at the end of 80s early 90s from South Korea to China, with its economy, optional color diversity, convenient construction method, excellent processing performance, excellent fire resistance and noble quality, quickly favored by people.

- Q: Hi,I need some interesting facts about AluminiumLike who found/discovered it, and how, or/and history of it. Recycling it, or does it have effects on the environment,Thanks if you can help,Thank you thank you thank you!Xx

- Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. all the ifo u need isat the link below

Send your message to us

4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords