DC Aluminium Coil - Aluminum 4 X 8 Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard seaworthy export packing or as your request One 20'GP can load about 20 tons of aluminum sheets; one 40'GP can load about 24tons. |

| Delivery Detail: | About 20 days after receiving the prepayment or the original L/C |

Specifications

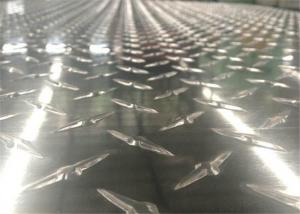

high quality hot rolled aluminium jumbo roll/coil prices 5052/5083/5754/5182

Strict quality control & competitive price

high quality hot rolled aluminium jumbo roll/coil prices/sheet price

Product Details:

Product Name | high quality hot rolled aluminium jumbo roll/coil prices/sheet price | |

Alloy No. | 5052/5083/5182/5752 | |

Temper | O, F, H12, H14, H16, H24, H26, H32, etc. | |

Thickness(mm) | 0.2 to 350 | |

Width(mm) | Up to 2280 | |

Length(mm) | Up to 12000 | |

MOQ | Normally 5 MT | |

Application | Cookware, Conductor, Decorations for Building, Vehicle & Ships, Instrument Board, Meter Housing, | |

Packing | Standard seaworthy export packing or as your request | |

Delivery Time | 10 to 20 days after receiving the prepayment or the original L/C | |

Terms of Payment | L/C at sight, L/L | |

Note | Specifications can be customized as the customer's requirements |

Packing Details:

1. Standard seaworthy export packing or as your request

2. One 20'GP can load about 20 tons of aluminum sheets; one 40'GP can load about 24tons.

Delivery Time:

10 to 20 days after receiving the prepayment or the original L/C

- Q: What are the specific rules or codes that govern the use of aluminum sheets in residential construction?

- <p>Yes, there are special regulations related to using aluminum sheets in residential buildings. These regulations can vary by country, state, or municipality, but generally, they cover aspects such as material standards, fire resistance, structural integrity, and energy efficiency. For example, aluminum sheets must meet specific thickness and strength requirements to ensure structural safety. They must also comply with fire codes, which may require certain fire-resistant coatings or treatments. Additionally, energy codes may dictate the insulation value of aluminum sheets used in walls or roofs to improve thermal performance. It's crucial to consult local building codes and regulations to ensure compliance when using aluminum sheets in residential construction.</p>

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- It’s useless. Aluminum foil will generate eddy and emit heat after medium induction, which will reduce the thermal efficiency of medium frequency. Now I provide a method for reference only. Induction coil will be water cooling and is packaged by thermal cement and other materials. Use asbestos sheet and other materials to transform the both ends of induction heating coil as baffle which is mobile and convenient for load and unload. When steel tube is heated in the induction coil, you can put down the baffle to prevent large loss of heat, shorten heat time and improve heat efficiency. When the seamless steel tube is heated into setting temperature, you can open the baffle to conduct expanding process, and you don’t need to think about the thermorytic problem of steel tube in the expanding process. It’s important to shorten the time of expanding process. Baffle is used for heat retaining of medium frequency heating and extrusion forming in our factory. The method above for reference only.

- Q: Can aluminum sheets be used together with other materials, specifically insulation materials?

- <p>Yes, aluminum sheets can be used in combination with other materials, including insulation materials. Aluminum is often used as a cladding material due to its durability and resistance to corrosion. When combined with insulation materials, it can enhance the thermal performance of a structure by reducing heat transfer. This combination is common in construction and roofing applications, where aluminum sheets can provide a protective outer layer while the insulation material manages thermal control. The use of aluminum with insulation materials can lead to energy-efficient buildings and improved indoor comfort.</p>

- Q: What is the typical sheet size tolerance for aluminum sheets?

- The typical sheet size tolerance for aluminum sheets can vary depending on the specific application and industry standards. However, in general, the industry standard for aluminum sheet size tolerance is typically around +/- 0.005 inches. This means that the actual size of the aluminum sheet can deviate up to 0.005 inches from the specified or desired size. It is important to note that this tolerance can be further reduced or increased based on the specific requirements of the project or customer preferences. Additionally, it is advisable to consult the manufacturer or supplier of the aluminum sheets to get the most accurate and up-to-date information on sheet size tolerances, as they may have specific guidelines or capabilities that differ from the industry standard.

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- How strong aluminum is, depends on the specific alloy of aluminum, whether it is the aluminum 1000 series, or the 3000 series, or the 6000 series, or other variants. The 6000 series is most common for structural purposes. Do a search on its yield strength and its ultimate tensile strength, to get an idea of how strong your particular variant is. The alloy Aluminum 6061-T6 has a yield strength of 35000 lb/in^2, and an ultimate tensile strength of 42000 lb/in^2. This is for the case of pure tension with a uniform load. The square inches refers to its cross sectional area. The ultimate strength occurs at the point where it will completely rupture. The yield strength occurs at the point, where it still supports the load, but ceases to be reversible after the load is removed. Pure aluminum metal is much weaker than its alloys. It has a yield strength of about 1500 psi, and an ultimate strength of 10000 psi. For structural purposes, you almost always want to stay below the yield strength. How stiff aluminum is, is common among all alloys, as 10000000 psi. That is to say 10 million pounds of tension on an aluminum member with a cross sectional area of 1 inch, would hypothetically cause an increase equal to 1 length, if it were still in-tact and linear-elastic at that amount of stress. It isn't. A more realistic case, would be that 10000 pounds of tension on this member, would cause an 0.1% increase in length. As for how light aluminum is per square inch, that depends upon how long your rod is. A 3 ft rod weighs 3 times as much per square inch as does a 1 ft rod. The weight of a material is measured PER UNIT VOLUME rather than per unit area. Unless you are talking about a standard thickness. Aluminum 6061 alloys have a density of 0.0975 pounds/cubic inch. Pure aluminum has a this density as well, as do most of its alloys.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating. The protective coating is applied to prevent scratches, corrosion, and other damages during transportation and handling. This coating ensures that the aluminum sheets are delivered to the customers in pristine condition.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- I'm going to show my calculations anyways Fe2O3(s) + 2 Al(s) -- 2 Fe (l) + Al2O3 (s) From the equation : 1 mole of iron (III) oxide 2 moles of aluminium -- 2 moles of iron 1 mole of aluminium oxide Given that iron = 10.0 g = 10.0 g / 55.8 g per mole = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to iron (III) oxide is 2 : 1 Therefore moles of iron (III) oxide produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (55.8 x 2 + 16.0 x 3) = 14.3 grams (corr to 3 sig fig)' a) 14.3 grams of iron (III) oxide must be used ----- Given that iron = ...... (previously calculated) ...... = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to aluminium is 1 : 1 Therefore moles of aluminium produced = 0.179 mol Convert it back to grams 0.179 x 27.0 = 4.83 grams (corr to 3 sig fig) b) 4.83 grams of aluminium must be used ----- Given that iron = 0.179 mol Because the mole ratio of iron to aluminium oxide is 2 : 1 Therefore moles of Al2O3 produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (27.0 x 2 + 16.0 x 3) = 9.13 grams (corr to 3 sig fig) c) 9.13 grams of aluminium oxide is the maximum mass that could be produced P.S. The relative molecular masses used are from my textbook

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties and is known for its ability to withstand the harsh conditions found in marine environments. Unlike many other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from saltwater and other corrosive elements. Additionally, aluminum is lightweight yet strong, making it an ideal choice for marine applications where weight reduction is important. It is commonly used in the construction of boats, ships, offshore structures, and other marine equipment.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

Send your message to us

DC Aluminium Coil - Aluminum 4 X 8 Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords