Aluminum Tread Plate Sheets for Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

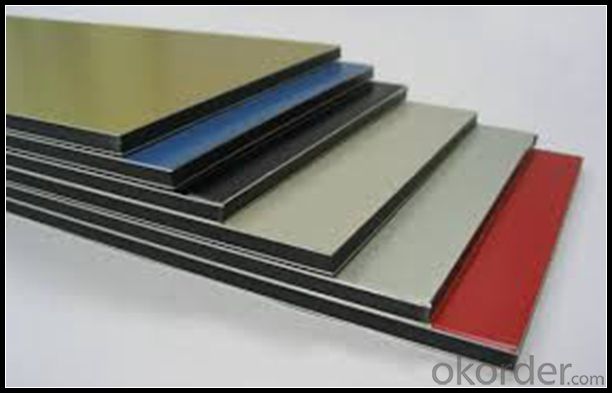

1.Structure of Aluminium Composite Panel for Curtain Wall System

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminium Composite Panel for Curtain Wall System

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

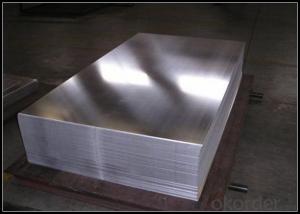

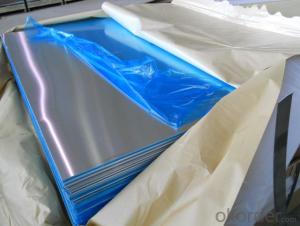

3. Aluminium Composite Panel for Curtain Wall System Images

4.Specification of Aluminium Composite Panel for Curtain Wall System

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Yes, aluminum sheets are suitable for pharmaceutical packaging due to their excellent barrier properties, light weight, and resistance to corrosion. They protect pharmaceutical products from moisture, light, and oxygen, ensuring their stability and extending their shelf life. Additionally, aluminum sheets can be easily molded into different shapes, making them a versatile choice for various packaging formats in the pharmaceutical industry.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can be a viable alternative to plastic in certain applications. Aluminum is a lightweight and durable material that offers numerous advantages over plastic. It has excellent strength-to-weight ratio, making it suitable for applications that require resistance to impact or heavy loads. Additionally, aluminum is highly resistant to corrosion, which makes it ideal for outdoor or marine applications where plastic may degrade over time. Moreover, aluminum is a highly recyclable material, which aligns with the growing emphasis on sustainability and reducing waste. Unlike plastic, which can take hundreds of years to decompose, aluminum can be recycled indefinitely without losing its properties. This makes aluminum a more environmentally friendly choice for applications where plastic waste is a concern. Furthermore, aluminum sheets offer superior thermal conductivity compared to plastic, making them suitable for applications that require heat dissipation or thermal management. This makes aluminum a preferred choice for products such as heat sinks or electronic enclosures. However, it's important to note that aluminum sheets may not always be the best alternative to plastic. Plastic offers certain advantages such as being lightweight, flexible, and cost-effective, which makes it more suitable for applications that require these properties. Additionally, plastic can be molded into complex shapes, making it preferable for certain designs. In conclusion, aluminum sheets can be an effective alternative to plastic in certain applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity are advantageous. However, the choice between aluminum and plastic ultimately depends on the specific requirements and constraints of the application at hand.

- Q: Can aluminum sheets be used for decorative panels?

- Yes, aluminum sheets can be used for decorative panels. Aluminum is a versatile material that can be easily shaped, textured, and colored, making it suitable for various decorative applications. Its lightweight nature, durability, and resistance to corrosion also make it a popular choice for decorative panels in both indoor and outdoor settings.

- Q: What is the elongation percentage of 101 aluminum sheets?

- The elongation percentage of 101 aluminum sheets refers to the amount of deformation or stretching the material can undergo before breaking. The exact elongation percentage of 101 aluminum sheets can vary depending on various factors such as the thickness of the sheets and the specific manufacturing process. However, in general, 101 aluminum alloy is known for its excellent formability and high elongation properties. It typically exhibits elongation percentages ranging from 10% to 30%, which means the material can stretch by that percentage of its original length before fracturing.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Please don't ask diffuse questions. If you mean a solution of aluminum ions Al+3, then no: Al3+ + 3e? ? Al(s) -1.66 Cu2+ + 2e? ? Cu(s) +0.340 Cu+ + e? ? Cu(s) +0.520 If you mean a solution of some unspecified Al compound then maybe, but there's no way to know until you specify the compound.

- Q: Need to polish some small aluminum tubing, preferably to chrome like shine. What tools do I need? Thinking about buying 6 bench grinder, buffing? wheels and polish compound... Does it sound about right?

- I've done all sorts of tests on this topic and am using a polishing kit that was meant for plastic, but on aluminum, but after all the pads coarse to fine (wet) I found that it's better to use the last pad again but dry, rather than using the while liquid paste they propose. Polishing dry or wet makes a difference, and polishing Al is not the same as polishing a plastic. It's a tricky recipe, you can dull your Al easily, and I never got it shiny like a mirror so I want to see other answrs

- Q: Can the aluminum sheets be used in food or beverage processing industries?

- Yes, aluminum sheets can be used in food or beverage processing industries. Aluminum is a commonly used material in these industries due to its excellent properties such as corrosion resistance, lightweight, and ability to withstand extreme temperatures. It is often used in food packaging, processing equipment, and beverage cans.

- Q: Can aluminum sheets be used for signage?

- Signage can indeed utilize aluminum sheets. Aluminum, a versatile and durable material, is frequently employed in the sign-making industry. Its lightweight yet sturdy properties make it well-suited for both outdoor and indoor signage. Additionally, aluminum sheets are resistant to corrosion, rust, and fading, guaranteeing signage longevity. They can also be easily cut and shaped into various sizes and designs, providing creative and customized signage solutions. Furthermore, the material offers a smooth surface that can be painted, printed, or laminated with graphics and text, making it highly adaptable for different signage applications. In conclusion, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a favored choice for signage.

Send your message to us

Aluminum Tread Plate Sheets for Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords