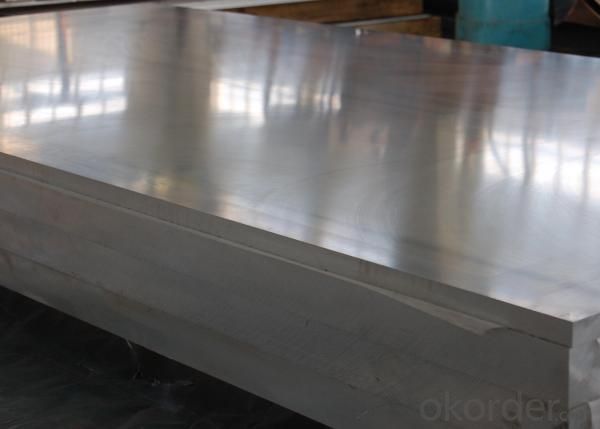

Colored Aluminum Sheets 4x8 - AA1050, AA1060, AA1070, AA1100

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information

Aluminum sheets is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum sheets which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

The main producing procedure includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

2. Technical Data

Alloy

AA1050,AA1060, AA1070, AA1100

Temper:

H12, H14, H16, H18, H22, H24, H26, H32,HO, F

Thickness:

0.10-500mm

Aluminized steel may be steel that might have been hot-dip coated on both sides with aluminium-silicon alloy. This process might assure a tight metallurgical bond between the steel sheet and its aluminium coating,possibly producing a material with a unique combination of properties possessed neither by steel nor by aluminium alone. Aluminized steel could show a better behavior against corrosion[1] and keeps the properties of the base material steel for temperature lower than 800 °C (1,470 °F). For example, it would be commonly used for heat exchangers in residential furnaces, commercial rooftop HVAC units, automotive mufflers, ovens, kitchen ranges, water heaters, fireplaces, barbecue burners, and baking pans. This steel could be very useful for heating things up because it transfers heat faster than most other steels.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Yes, aluminum sheets can be suitable for electrical bus bars in certain applications. Aluminum has several properties that make it a viable option for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in applications where weight reduction is important. Additionally, aluminum has good electrical conductivity, although it is not as conductive as copper. However, aluminum bus bars can still handle high electrical currents and are commonly used in power distribution systems. One downside of aluminum bus bars is that they have a higher resistance compared to copper bus bars. This means that they can generate more heat, especially under high current loads. To mitigate this issue, aluminum bus bars are often designed with larger cross-sectional areas to reduce resistance and dissipate heat more effectively. Another challenge with aluminum bus bars is their susceptibility to oxidation and corrosion. This can be addressed by applying protective coatings or using alloys with better corrosion resistance. It is also important to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In summary, aluminum sheets can be suitable for electrical bus bars, especially in applications where weight reduction is important. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: What are the dimensions and thickness options for aluminum sheets?

- The dimensions and thickness options for aluminum sheets vary depending on the specific requirements and applications. Aluminum sheets are available in a wide range of sizes and thicknesses to suit different needs. In terms of dimensions, aluminum sheets can be found in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. These dimensions can, however, vary depending on the supplier and specific product. The thickness options for aluminum sheets also vary. The thickness is typically measured in gauge, with lower gauge numbers indicating thicker sheets. Aluminum sheets are available in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It's important to note that specific dimensions and thickness options may vary depending on the supplier and the specific grade of aluminum being used. It is always recommended to consult with a supplier or manufacturer for precise information on available dimensions and thickness options for aluminum sheets.

- Q: Is it possible to utilize aluminum sheets in a home renovation project?

- <p>Yes, you can use aluminum sheets for your home renovation project. Aluminum is a versatile material known for its strength, durability, and resistance to corrosion. It's commonly used for roofing, siding, and even for decorative purposes. Aluminum sheets are lightweight, easy to install, and can be painted or coated to match your home's aesthetic. They also offer good thermal performance and can be recycled, making them an environmentally friendly choice. However, it's important to consider the specific requirements of your project, such as the local climate, design preferences, and budget, to ensure aluminum is the best fit.</p>

- Q: What is the thermal conductivity of 101 aluminum sheets?

- The thermal conductivity of 101 aluminum sheets depends on various factors such as the thickness of the sheets, the purity of the aluminum, and the temperature at which the measurement is taken. Generally, aluminum has a high thermal conductivity, ranging from 205 to 250 watts per meter kelvin (W/mK). However, it is advisable to refer to specific technical data or consult with a manufacturer for accurate information on the thermal conductivity of 101 aluminum sheets.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used as reflective surfaces due to their high reflectivity and low emissivity properties.

- Q: Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications.

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: This question asks for a detailed explanation of the steps involved in the manufacturing process of aluminum profiles specifically designed for use as exterior cladding.

- <p>The process for manufacturing aluminum profiles for exterior cladding involves several key steps. First, aluminum ingots are melted in a furnace. The molten aluminum is then poured into molds to create extrusion billets. These billets are heated and fed into an extrusion press where they are forced through a die with the desired profile shape. After extrusion, the profiles are cooled and then cut to length. They may undergo further processing such as anodizing, painting, or powder coating to enhance their durability and appearance. Finally, the profiles are inspected for quality, packaged, and shipped to construction sites for installation as exterior cladding.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Colored Aluminum Sheets 4x8 - AA1050, AA1060, AA1070, AA1100

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords