Aluminum Composite Panel 4x8 Sheets - Small Five Bar Treadplate for Car Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Small Five Bar Treadplate for making car flooring

CC Aluminium sheet for making trailer is one semi-finished aluminium material. This sheet can be cut to size you wanted in production. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Small Five Bar Treadplate for making car flooring

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Small Five Bar Treadplate for making car flooring

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Small Five Bar Treadplate for making car flooring

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Small Five Bar Treadplate for making car flooring

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

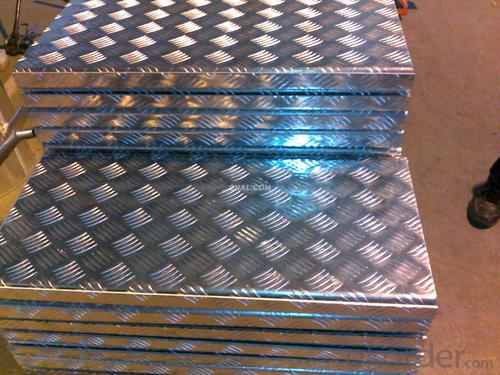

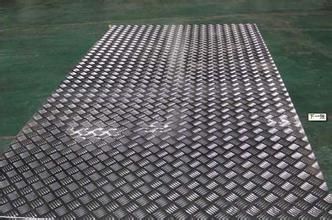

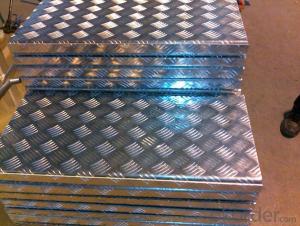

6. Image of Small Five Bar Treadplate for making car flooring

7. Package and shipping of Small Five Bar Treadplate for making car flooring

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Indeed, the utilization of aluminum sheets in the manufacturing of food packaging is feasible. Owing to its diverse characteristics, aluminum has become a favored option for food packaging. Its lightweight nature, resistance to corrosion, and exceptional heat conductivity are among the reasons for this preference. These attributes render it suitable for safeguarding the freshness and quality of food items. Moreover, aluminum possesses impermeability to light, moisture, and oxygen, thereby aiding in the extension of the shelf life of food products. Furthermore, the malleability of aluminum sheets enables them to be effortlessly molded into various shapes and sizes, thus facilitating tailored packaging solutions. In essence, the food packaging industry frequently relies on aluminum sheets due to their adaptability, durability, and their ability to ensure the safety and integrity of food items.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a good conductor of electricity and is commonly used in the production of electrical connectors due to its lightweight, corrosion resistance, and cost-effectiveness.

- Q: Are aluminum sheets suitable for food-grade applications?

- Yes, aluminum sheets are suitable for food-grade applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it a suitable choice for food processing and packaging. Aluminum sheets can be used to make food-grade containers, trays, and packaging materials. They are also commonly used for cooking utensils, such as baking sheets and foil, which are safe to use in direct contact with food. Additionally, aluminum sheets can be easily cleaned and sanitized, making them a hygienic choice for food-grade applications.

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms. Aluminum is a highly malleable metal, which means it can be easily manipulated without breaking or cracking. Its low density and high strength-to-weight ratio make it an ideal choice for various applications where shaping or bending is required. Aluminum sheets can be shaped or bent using a variety of methods, including press-braking, roll-forming, or using specialized tools such as a sheet metal brake. The ease of shaping or bending aluminum sheets also makes it a popular choice for industries such as automotive, aerospace, construction, and manufacturing, where customized forms and designs are often needed.

- Q: What are the common thicknesses of aluminum sheets used in transportation industry?

- The common thicknesses of aluminum sheets used in the transportation industry typically range from 0.032 inches to 0.125 inches.

- Q: I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- Depends on what you're planning on doing with them really. But definitely no on the fiberglass. Long distance shots (50m), definitely carbon. Certain carbons do last longer, I shoot Carbon Express Nano XR, built like a tank, no aluminum comes close to the durability. Before this, I've shot ACE, built for speed and breaks left and right. So, moral of the story is, carbon's durability depends on make and model. Sadly, I have to disagree with DumDum this time around about the carbon's rigidity. For a given shaft weight, the carbon shaft will bend less than aluminums. However, for a given bow/archer setup, you need carbon shafts that bends as much as aluminum for that same setup. The basis of bow tuning is this requirement that the arrow need to bend a certain amount during the shot. Take away the bending and the arrow won't fly straight, hence the archer's paradox. Given a well tuned setup, the only variables to penetration is the KE, and the surface friction as the arrow enters the target.

- Q: Calculate the mass in grams of Iodine (I2) that will react completely with 20.4 g of aluminum to form aluminum oxide (AlL3)

- Aluminium oxide? Shouldn't it be Aluminium iodide? 1. Form a balanced equation 3I2 + 4Al - 2Al2I3 2. Number of moles of Al 20.4/(Mr of Al) = 20.4/27 = 0.7555mol 3. Number of moles of I2 0.7555/4 x 3 = 0.5666mol 4. Mass of I2 required = 0.5666 x Mr of I2 = 0.5666 x (127x2) Ans: 143.9164g

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

Send your message to us

Aluminum Composite Panel 4x8 Sheets - Small Five Bar Treadplate for Car Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords