Wholesale 3-50mm Thick 5083 H32 H321 Marine Aluminum Plate Aluminum Profile Aluminum Reinforcement

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

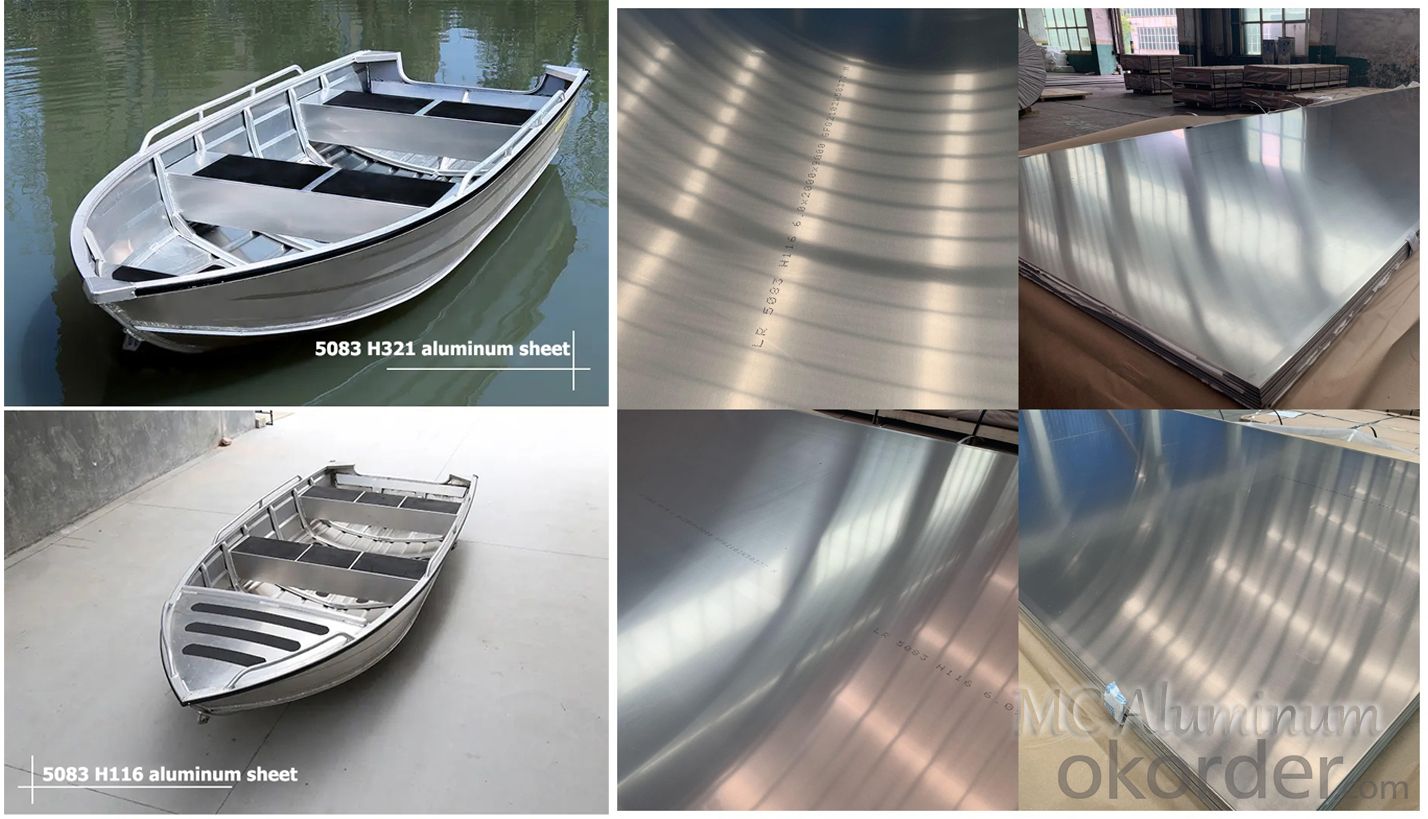

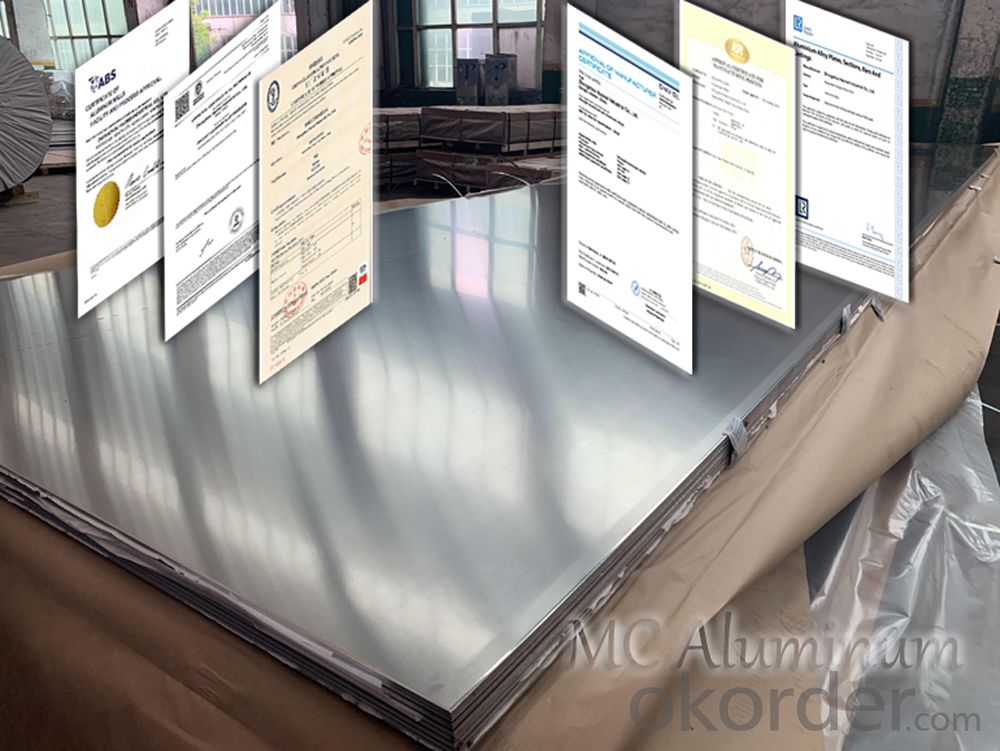

Marine-grade aluminum sheets produced by Henan Hongchang Aluminum are often used as reinforcements for shipbuilding hulls and other components. They have good mechanical properties such as strength, heat treatability, processability and weldability. We provide aluminum alloy plates and profiles with thicknesses of 3-50mm, including 5052, 5083, 5086, 5754 and 6061 aluminum plates, etc., and have obtained certificates from classification societies such as LR, BV, DNV, and ABS.

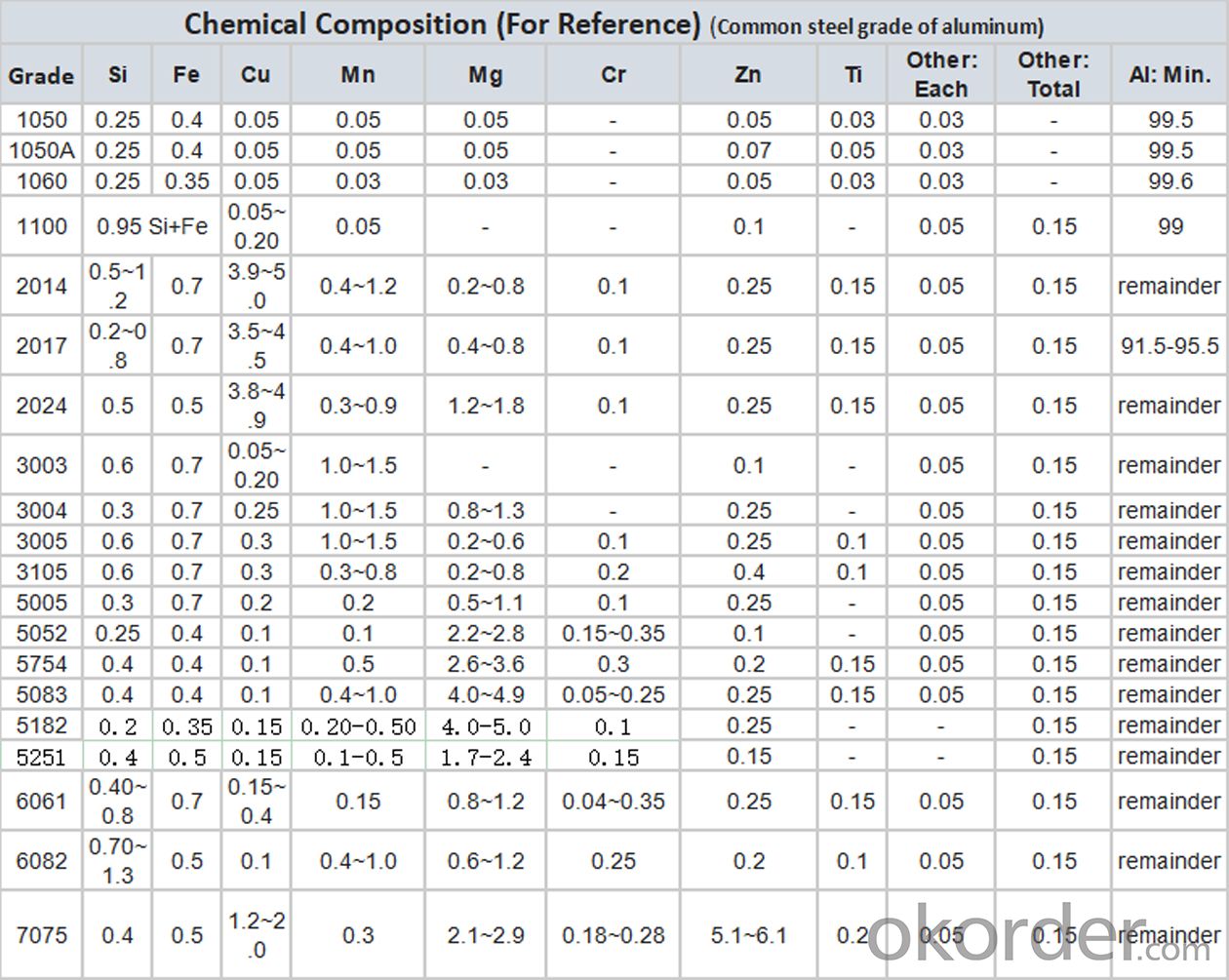

Chemical composition of aluminum alloy ship plates

Performance advantages of marine grade aluminum plates:

1. Corrosion-resistant, reducing oiling and other costs and extending service life

2. Small specific gravity, which can reduce ship weight, save energy consumption and increase load capacity

3. Good welding and processing formability, which is convenient for later processing

4. Recyclable and reusable

5. Fireproof, high temperature resistant

6. High strength and strong impact resistance

- Q: What is the weight of a standard aluminum sheet?

- The weight of a standard aluminum sheet can vary depending on its thickness, dimensions, and grade. On average, a standard aluminum sheet weighs around 2.7 grams per cubic centimeter (g/cm³).

- Q: Can aluminum sheets be anodized in different colors?

- Yes, aluminum sheets can be anodized in different colors. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum. By immersing the aluminum sheet in an electrolyte bath and applying an electric current, a controlled oxidation process occurs, resulting in a thick and durable layer of oxide on the surface. During the anodizing process, various dyes can be added to the electrolyte bath, allowing the aluminum to absorb the dye molecules and create a colored oxide layer. This allows for a wide range of colors to be achieved, including red, blue, green, yellow, and many others. Additionally, the intensity and shade of the color can be controlled by adjusting factors such as the concentration of the dye and the voltage applied during the anodizing process. The anodized layer formed on the aluminum sheet not only provides a vibrant and aesthetically pleasing appearance but also improves its corrosion resistance and durability. This makes anodized aluminum sheets an excellent choice for architectural, decorative, and industrial applications where color customization is desired while maintaining the inherent benefits of aluminum.

- Q: What is the modulus of elasticity for aluminum sheets?

- The modulus of elasticity for aluminum sheets, also known as Young's modulus, is typically around 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This value represents the measure of the stiffness or rigidity of the material. However, it is important to note that the modulus of elasticity can vary slightly depending on the specific alloy composition and tempering of the aluminum sheet.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- Let me guess, making thermite? :P The easiest way by far to get aluminum I have found is breaking open an old EtchaSketch. That's aluminum powder in there. There are too many impurities on the can to make it easy, go to the dump and find some old EtchaSketches. Addition: Do NOT breathe in the powder, its not good for your system, it does large amounts of damage to your lungs, I suggest wearing a mask of some sort for safety. Do not take it lightly. Otherwise, have fun melting holes in the ground / someone's car / a safe / anything else you can get your hands on :P

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating. The protective coating is applied to prevent scratches, corrosion, and other damages during transportation and handling. This coating ensures that the aluminum sheets are delivered to the customers in pristine condition.

- Q: What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20 to 35 MPa√m.

- Q: I have a set of Chrome Aluminum rims, and two of them have scratches on them. So instead of buying new ones, is it possible to paint them. I was thinking black.

- Chrome Paint For Rims

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: What are the aluminum plates for?

- The products are widely used in construction, curtain wall, packaging, food, air conditioners, refrigerators, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, cosmetics packaging and other electrical appliances, machinery manufacturing industry, can also be used in power plants, chemical and petrochemical industry factory anticorrosion & insulation etc..Shandong Pingyin Hengshun Aluminium Co., Ltd. specializing in the production of (hot rolling, cold rolling aluminum alloy) roll. Aluminum coil. Alloy aluminum. Aluminum. Ultra wide / ultra thick aluminium alloy. Sawing, shearing customer requirements specification aluminum alloy thick aluminum wire, aluminum, aluminum flange with aluminum, power plant / chemical anticorrosion and insulation alloy factory aluminum moisture-proof aluminum roll roll.

Send your message to us

Wholesale 3-50mm Thick 5083 H32 H321 Marine Aluminum Plate Aluminum Profile Aluminum Reinforcement

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords