Painted 4 X 8 Five Bar Aluminum Sheet / Treadplate (Embossed, Stucco Sheet)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

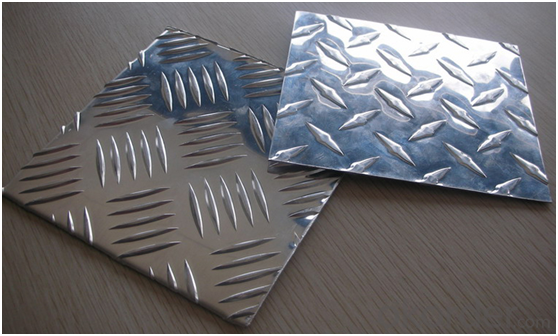

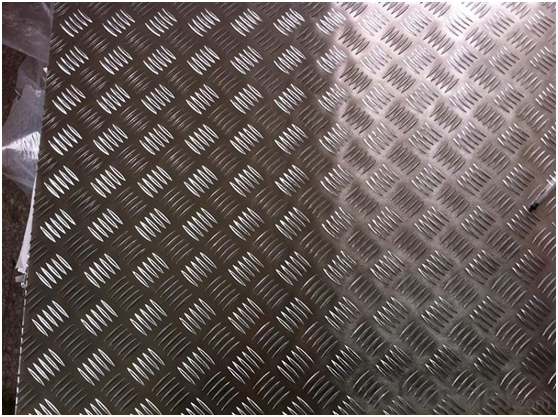

Aluminum Tread Plate

l Production Introduction

| Alloy | 1050,1060,1100,3003,3004,5052 |

| Temper | O H12 H14 H16 H18 H22 H24 H26 H32 |

| Thickness | 0.2mm-3.0mm |

| Width | 500mm-1500mm |

| Length | As your requirement |

| MOQ | 2.5MT |

| Delivery time | 15-25 days after receiving the deposit. |

| Payment | T/T 30% deposit,T/T 70% against copy of BL OR 100% LC at sight |

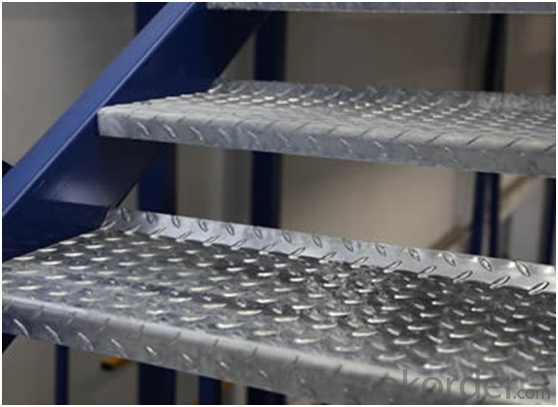

| Application | furniture, the refrigerator, air conditioning, car and platform, screen skeleton, all kinds of suspension beam, the table a foot, adornment, handle, trough and cover, chair pipe |

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool; Third, wooden cases with dry agent, without fumigation, wooden pallets

Delivery detail: Within 25days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium treadplate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- Why in the name of G-d are solar panel installations using higher than 600 volts? I can't imagine the clearances in the panels will stand 10,000 volts without jumping arcs. It is true that the rubber insulation used on most wiring is rated at 600 volts breakdown - special neon rated wire is used for higher voltages, which can also be copper. When you say electric fence wire, you actually mean the short wires that run from the high voltage source to the end of the bare wires which are usually steel to withstand the force of animals who bump into them before the shock drives them off and which is the wire most of us think of as fence wire. There is a problem using aluminum wire, especially in houses, because it forms a hard oxide surface very quickly and expands and contracts more than copper, so it must be used with special connectors that break through the layer and grease that keeps off the air. If you are using 8 gauge wire, you are doing it because of fairly high amps, which usually involves low voltages and solar arrays I have looked into have been 12, 24 and 48 volts. If your system is putting out 30-40 amps at 600 volts, you are 18,000 watts or more through 1 set of wires. Really? Or am I mixing two systems?

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is commonly used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance, making it suitable for various structural applications in aircraft and spacecraft.

- Q: What are the different surface finishes for aluminum sheets in the construction industry?

- The construction industry presents various options for surface finishes on aluminum sheets. These finishes aim to improve the appearance and durability of the aluminum, making it suitable for diverse construction applications. One prevalent surface finish for aluminum sheets is the mill finish. This finish refers to the raw, untreated surface of the aluminum, which may exhibit minor imperfections or scratches. Mill finish finds common use in applications where appearance is not a significant concern, such as structural components or industrial projects. Another well-liked surface finish is the anodized finish. Anodizing involves an electrochemical process that forms a protective layer on the aluminum's surface, enhancing its resistance to corrosion and wear. Anodized finishes come in various colors, allowing for greater design flexibility in construction projects. They are commonly employed for architectural elements like window frames, facades, and decorative panels. Painted finishes are also frequently employed in the construction industry. Aluminum sheets can be coated with a layer of paint, providing aesthetic appeal and additional protection against corrosion. Painted finishes can be customized to meet specific design requirements, making them suitable for a wide range of construction applications. Additionally, brushed finishes find extensive use in the construction industry. Brushing is a mechanical process that creates a textured surface on the aluminum, resulting in a unique, matte appearance. This finish is commonly utilized for decorative purposes, such as interior wall panels or furniture in commercial spaces. In conclusion, the construction industry offers a range of surface finishes for aluminum sheets, including mill finish, anodized finish, painted finish, and brushed finish. Each finish possesses its own distinctive properties and advantages, enabling greater versatility and customization in construction projects.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications. 101 aluminum is a commercially pure aluminum alloy that has low electrical conductivity. It is not able to efficiently conduct heat, making it unsuitable for applications where heat transfer is desired. For conductive heat transfer applications, it is better to use alloys that have higher thermal conductivity, such as 6061 or 7075 aluminum. These alloys have better heat transfer properties and are commonly used in heat sinks, heat exchangers, and other applications where efficient heat transfer is required.

- Q: Can aluminum sheet be used for aircraft skin panels?

- Yes, aluminum sheet can indeed be used for aircraft skin panels.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q: Which is better aluminum or stainless steel?

- Depending on what your using it for. Stainless steel is much stronger in strength seeing Aluminum has it's weak points and can bend under stress, and is also weak under large amounts of heat. I use stainless steel bolts and nuts for my exhaust systems, and starters on my truck, and they still haven't rusted as of yet.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- Yes, in this case. Long ago, house wiring was allowed with aluminum wiring. But, shorts were resulting from dissimilar metals touching, while conducting large current and in the presence of electrolitic moisture. The dissimilar metals touching was a problem due to electrolytic corrosion taking place- any time two dissimilar metals come in contact in the presense of an electrolytic solution, corrosion takes place. However, in your case, you are connecting a ground wire, that does not normally conduct- it will only conduct in case of a short or other failure to ground. You are not installing this in a place where salty, moist air is a concern (the electrolyte)- so, it's okay.

- Q: What are the common thicknesses of aluminum sheets used in construction?

- The common thicknesses of aluminum sheets used in construction vary depending on the specific application and requirements. However, some commonly used thicknesses include 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are often used for architectural applications such as wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), are also used in heavier construction applications such as structural components, support beams, and decking. It is important to note that these thicknesses are just examples and can vary depending on the specific project requirements and engineering specifications.

Send your message to us

Painted 4 X 8 Five Bar Aluminum Sheet / Treadplate (Embossed, Stucco Sheet)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords