4 X 8 Aluminum Sheets for Sale - DIN 1747 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Auminium Sheet with German Standard DIN 1747 Description

Auminium Sheet with German Standard DIN 1747 is semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Auminium Sheet with German Standard DIN 1747

Auminium Sheet with German Standard DIN 1747 | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Auminium Sheet with German Standard DIN 1747

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Auminium Sheet with German Standard DIN 1747

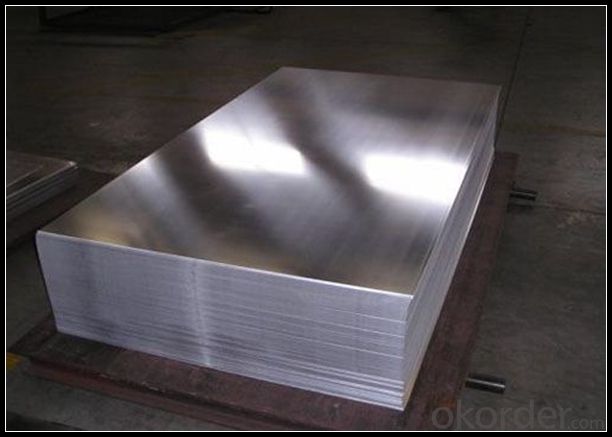

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Auminium Sheet with German Standard DIN 1747

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

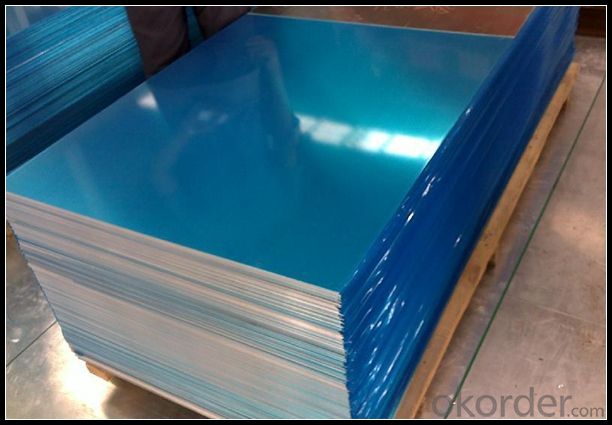

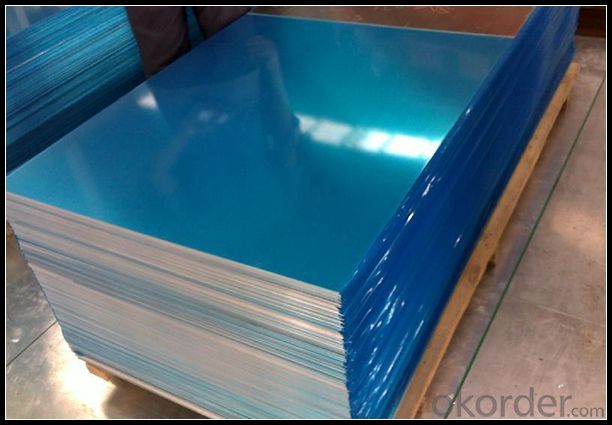

6. Image of Auminium Sheet with German Standard DIN 1747

7. Package and shipping of Auminium Sheet with German Standard DIN 1747

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for furniture manufacturing?

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a versatile material with several advantageous properties that make it suitable for furniture production. It is lightweight, durable, corrosion-resistant, and can be easily molded into various shapes and sizes. Additionally, aluminum has a sleek and modern aesthetic, making it a popular choice for contemporary furniture designs. Aluminum sheets can be used to create frames, legs, and other structural components for different types of furniture, including chairs, tables, shelves, and cabinets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, especially for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: is general aluminum sheet fire-proof?

- aluminum products has low melting point and is nonfireproof,and aluminum alloys will be better.

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets have excellent fire resistance properties. Due to their high melting point, they can withstand extreme heat and do not contribute to the spread of fire. Additionally, aluminum forms a protective oxide layer when exposed to fire, which further enhances its fire resistance capabilities.

- Q: What are the different surface patterns available for aluminum sheets?

- Depending on the desired aesthetic and functional requirements, aluminum sheets can exhibit a range of surface patterns. Some commonly used patterns include: 1. Smooth Finish: This basic pattern offers a flat and polished appearance, ideal for applications that prioritize a clean and sleek look, such as architecture and interior design. 2. Stucco Embossed: Featuring a raised texture resembling stucco, this pattern enhances durability and slip resistance. It is suitable for surfaces like stair treads or ramps that require a non-slip surface. 3. Diamond Tread: This pattern consists of raised diamonds on the surface, providing superior traction and slip resistance. It is commonly used in applications where safety is a concern, such as vehicle running boards or industrial flooring. 4. Hammered Finish: Creating a textured appearance similar to hammered metal, this pattern adds visual interest and can be used to enhance the aesthetics of architectural elements, decorative panels, or furniture. 5. Brushed Finish: Also known as satin finish, this pattern is achieved by brushing the aluminum sheet in a linear direction. It creates a smooth and consistent texture, often used for decorative purposes in applications like signage, wall cladding, or kitchen appliances. 6. Perforated: In this pattern, the aluminum sheet is punctured with small holes or slots in a specific design or pattern. It allows for airflow, light transmission, and sound absorption, making it suitable for applications like ventilation systems, acoustic panels, or decorative screens. These examples illustrate the variety of surface patterns available for aluminum sheets. The choice of pattern depends on the intended use, desired appearance, and functional requirements of the application.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The fourth one.

- Q: This question asks for a list of various adhesive types that are suitable for bonding aluminum sheets together.

- <p>There are several types of adhesives used for bonding aluminum sheets, including epoxy adhesives, which are strong and resistant to heat and chemicals; acrylic adhesives, known for their flexibility and UV resistance; cyanoacrylate or super glue, which offers fast bonding; polyurethane adhesives, providing excellent adhesion and durability; and silicone adhesives, which are great for high-temperature applications. Each type has its specific properties and applications, making them suitable for different bonding requirements and environmental conditions.</p>

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- Embedded aluminum roof flashing, aluminum water stops, aluminum electrical conduit, introduced aluminum powder (sometimes used to foam concrete), or embedded structural aluminum shapes may all corrode in concrete or mortar. In all cases, a reaction that forms aluminum hydroxide and hydrogen gas occurs, and may cause expansion and cracking of the concrete or mortar. The common use of calcium chloride (or other alkali compounds), and dampness of the concrete increases the reaction rate. Usually, coating the aluminum with bituminous paint, impregnated paper or felt, plastic, or an alkali-resistant coating will prevent or sharply reduce the corrosion.

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Aluminum sheets are indeed a fantastic option for embellishing lighting fixtures. This material, known for its lightweight and versatility, can be effortlessly fashioned into diverse shapes and designs. Moreover, aluminum boasts exceptional resistance against corrosion, rendering it fitting for both indoor and outdoor lighting fixtures. Furthermore, aluminum can be conveniently coated or painted to achieve diverse finishes, offering limitless design prospects. Additionally, its reflective qualities enhance the overall lighting effect, making it an ideal preference for decorative lighting fixtures.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are highly weather-resistant due to their natural oxide coating, which provides excellent corrosion resistance against various weather elements such as rain, snow, UV radiation, and temperature changes. This oxide layer acts as a protective barrier, preventing the metal from further oxidation and degradation. Consequently, aluminum sheets retain their structural integrity and appearance even when exposed to harsh weather conditions for extended periods.

Send your message to us

4 X 8 Aluminum Sheets for Sale - DIN 1747 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords