1.5mm 4X8 Hard Stainless Steel Sheets 201

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

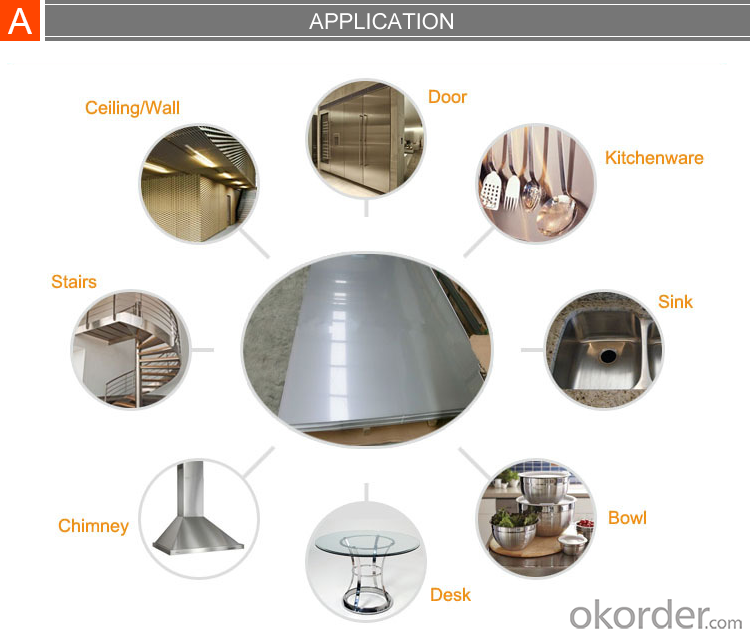

304 St 304 Stainless Steel Sheet ainless Steel Sheet MetalLow Price 2B 1.5mm 4X8 Hard Stainless Steel Sheets 201

Product Description

![]()

Material | 201 304 410 409 430 |

Technology | Cold Rolled |

Thickness | 0.12 mm~2.0mm (tolerances ±0.02 mm) |

Width | 10.0 mm ~1240 mm (tolerances ±0.02 mm) |

Processing | Pickling / Straighten / Flatten / Leveling |

Form | Rolling Coils / Cutting Sheets / Stamping Circles |

Edge | Mill Edge / Slitting Edge |

Annealed | Full hardness to Deep drawing quality (DDQ) |

Surface | BA - processed with bright heat treatment after cold rolling. |

2B - after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | |

2D – matt finish, best choice for deep drawing | |

Protection | 1. Inter paper available |

2. PVC protecting film available | |

All standard products are supplied without inter paper & PVC film. If needed, please inform. | |

Chemical and Mechanical Properties:

GRADE | C | Mn | Si | P | S | Cr | Ni | Cu | T.S. Mpa/min | P.S. Mpa/min | Elongation (%) |

304 | 0.04-0.06 | 1.0-1.2 | 0.25-0.45 | ≤0.40 | 18.1~18.5 | 8~8.2 | ≤0.50 | ||||

409L | ≤0.08 | ≤1 | ≤1 | ≤0.05 | ≤0.03 | 10.5-11.75 | - | 380 | 205 | 22 | |

410 | ≤0.15 | ≤1 | ≤1 | ≤0.04 | ≤0.03 | 11.5-13.5 | ≤0.75 | - | 440 | 205 | 20 |

430 | ≤0.12 | ≤1 | ≤0.75 | ≤0.04 | ≤0.03 | 16-18 | ≤0.75 | - | 450 | 205 | 22 |

201 High Cu | ≤0.15 | 5.5-7.5 | ≤0.75 | ≤0.06 | ≤0.03 | 13.5-15.0 | 1.2-1.5 | 1.4-1.5 | 520 | 275 | 55 |

201 Half Cu | ≤0.15 | 5.5-7.5 | ≤0.75 | ≤0.06 | ≤0.03 | 13.5-15.0 | 1.2-1.5 | 0.8-1.0 | 520 | 275 | 55 |

- Q: Are stainless steel sheets heat resistant?

- Indeed, stainless steel sheets exhibit exceptional resistance to heat. Renowned for their ability to withstand high temperatures and corrosion, stainless steel sheets are highly suitable for a wide range of applications. They maintain their structural integrity even under intense heat, without warping, melting, or compromising their integrity. This remarkable heat resistance can be attributed to the presence of chromium in stainless steel, which forms a protective oxide layer on the surface, preventing oxidation and preserving its strength at elevated temperatures. Consequently, stainless steel sheets are extensively utilized in vital industries like manufacturing, construction, automotive, and food processing, where the ability to withstand heat is paramount.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. They are strong, durable, and resistant to corrosion, making them ideal for long-term storage. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for both residential and commercial storage cabinets.

- Q: Are stainless steel sheets resistant to UV radiation?

- Generally, stainless steel sheets have resistance to UV radiation. The composition of stainless steel consists mainly of iron, chromium, and other alloying elements, which contribute to its exceptional resistance to various types of corrosion, including UV radiation. The presence of chromium in stainless steel leads to the formation of a protective oxide layer on the surface, acting as a shield against UV rays and preventing oxidation or deterioration of the metal. Nevertheless, it is worth noting that continuous exposure to intense UV radiation can still result in some discoloration or fading of the stainless steel surface over time. To preserve the appearance and durability of stainless steel sheets used outdoors, it is advisable to regularly clean and apply appropriate treatments to protect the surface and ensure long-lasting performance.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Indeed, fire-rated applications can certainly benefit from the use of stainless steel sheets. Renowned for its exceptional resistance to heat and fire, stainless steel proves to be a dependable option for such purposes. Its elevated melting point and robust structural integrity allow it to withstand high temperatures without succumbing to deformation. Moreover, stainless steel remains non-combustible and does not emit toxic fumes when exposed to heat, a critical factor in fire-rated applications where safety takes precedence. Consequently, stainless steel sheets are frequently utilized in fire-resistant doors, walls, and various structural elements, bolstering fire resistance and preventing the propagation of flames.

- Q: How do I choose the appropriate gauge for stainless steel sheets?

- When choosing the appropriate gauge for stainless steel sheets, there are a few factors to consider. First, you need to determine the intended use of the sheets. Thicker gauges offer more strength and durability, making them suitable for heavy-duty applications like industrial machinery or construction. If you require flexibility or a lighter weight, thinner gauges may be more appropriate for applications such as automotive or decorative purposes. Additionally, consider the environmental conditions the sheets will be exposed to, as this may affect the required gauge for corrosion resistance. Ultimately, consulting with a stainless steel supplier or industry expert can help you select the most suitable gauge based on your specific needs.

- Q: What are the different types of stainless steel alloys used for sheets?

- There are various types of stainless steel alloys used for sheets, each with its own unique properties and applications. Some of the commonly used stainless steel alloys for sheets include: 1. Austenitic Stainless Steel: This type of stainless steel is the most commonly used and offers excellent corrosion resistance, high ductility, and good formability. It is often used in food processing, chemical equipment, and architectural applications. 2. Ferritic Stainless Steel: Ferritic stainless steel alloys are known for their high resistance to stress corrosion cracking and good thermal conductivity. They are commonly used in automotive exhaust systems, heat exchangers, and appliances. 3. Martensitic Stainless Steel: Martensitic stainless steel alloys are known for their high strength, hardness, and wear resistance. They are commonly used in cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel: Duplex stainless steel alloys combine the properties of both austenitic and ferritic stainless steels. They offer excellent corrosion resistance, high strength, and good weldability. They are commonly used in oil and gas industry equipment, chemical processing, and marine applications. 5. Precipitation-Hardening Stainless Steel: These alloys are heat treatable and offer high strength, good corrosion resistance, and excellent toughness. They are commonly used in aerospace components, nuclear industry, and high-performance applications. Each type of stainless steel alloy has its own specific composition and properties, making them suitable for different applications. The choice of alloy depends on factors such as corrosion resistance requirements, strength requirements, and the environment in which the sheets will be used.

- Q: How do stainless steel sheets differ from other types of sheets?

- Stainless steel sheets set themselves apart from other types of sheets primarily due to their composition and distinctive properties. Unlike sheets made from materials like aluminum, brass, or copper, stainless steel sheets are manufactured using an alloy of iron, chromium, and other elements. The corrosion resistance of stainless steel sheets is one of the key distinctions. By adding chromium to the alloy, a passive layer forms on the surface of the sheet, safeguarding it against rust and corrosion. As a result, stainless steel sheets are highly durable and well-suited for diverse applications, particularly in environments exposed to moisture, chemicals, or extreme temperatures. Another factor that distinguishes stainless steel sheets is their strength and toughness. They possess exceptional mechanical properties, including high tensile strength, which renders them resistant to deformation and damage. Consequently, stainless steel sheets are more dependable and long-lasting compared to other sheet types. Moreover, stainless steel sheets offer an extensive range of aesthetic possibilities. They can be easily customized with various finishes, such as brushed, polished, or embossed, to achieve different appearances and textures. This versatility in design makes stainless steel sheets a popular choice in architectural, interior design, and decorative applications. Furthermore, stainless steel sheets boast excellent hygiene properties, qualifying them for use in the food and healthcare industries. They are easy to clean, non-porous, and non-reactive, preventing the growth of bacteria and ensuring the safety and cleanliness of the surfaces they cover. In conclusion, the unique characteristics of stainless steel sheets, including their corrosion resistance, strength, durability, aesthetic options, and hygiene properties, distinguish them from other sheet types. As a result, stainless steel sheets serve as a versatile and reliable choice for a wide range of applications across various industries.

- Q: What are the different types of stainless steel sheet alloys?

- There are several different types of stainless steel sheet alloys, including austenitic, ferritic, martensitic, and duplex stainless steel. Each alloy has unique characteristics and is suitable for various applications based on factors such as corrosion resistance, strength, and heat resistance.

- Q: Are stainless steel sheets scratch-resistant?

- Stainless steel sheets, in general, have the ability to resist scratches. The durability and scratch-resistant nature of stainless steel make it a suitable material for different uses, such as kitchen appliances, countertops, and decorations. Nevertheless, it is crucial to bear in mind that even though stainless steel exhibits high resistance against scratches, it is not entirely impervious to them. The surface of stainless steel sheets can still be scratched or marked if sharp objects or abrasive materials are used, particularly with excessive force or repeated contact. By regularly maintaining and properly caring for stainless steel sheets, the visibility of scratches can be minimized, ensuring they remain in their best condition.

Send your message to us

1.5mm 4X8 Hard Stainless Steel Sheets 201

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords