Lightweight Aluminum Sheet for Automobile Skin 5052-H32 5754 6061 7075

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

With the continuous development of automobile lightweight technology, automobile body aluminum sheet has become one of the indispensable key materials in the automobile manufacturing industry. Its characteristics and applications have an important impact on the performance, safety and fuel economy of the automobile.

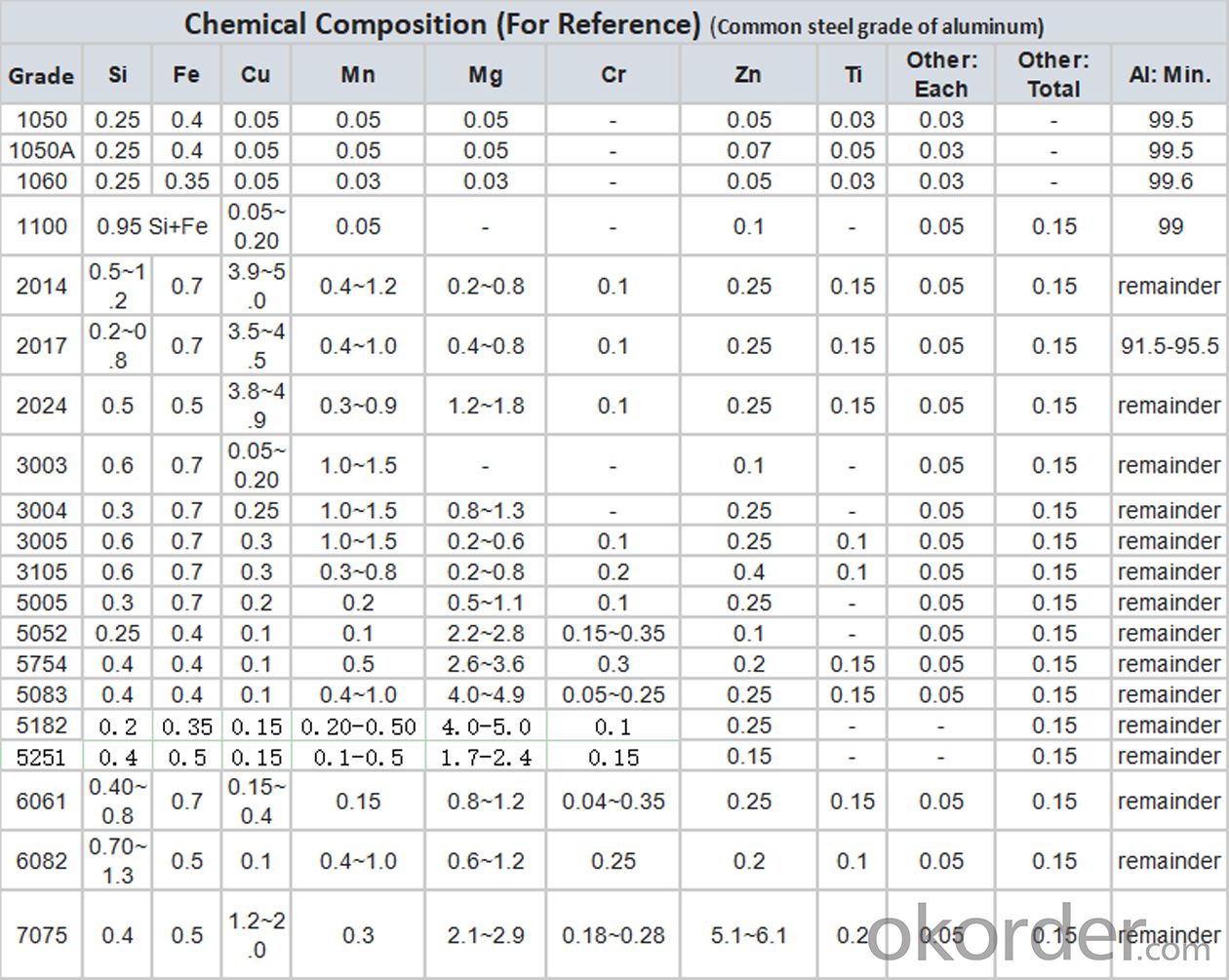

Automobile body aluminum sheet mainly includes the following types:

5000 series: such as 5052, 5754, etc. These alloys have medium yield strength and tensile strength, good corrosion resistance and processing performance, and are widely used in automobile inner panels, doors, engine hoods and other parts.

6000 series: such as 6016, 6061, etc. These alloys are heat-treatable aluminum alloys with high strength, good formability and corrosion resistance. They are often used in automobile chassis, suspension components and other structural parts.

7000 series: such as 7075, etc. These alloys have excellent strength and toughness, but relatively poor formability, and are usually used for parts with extremely high strength requirements, such as racing car bodies.

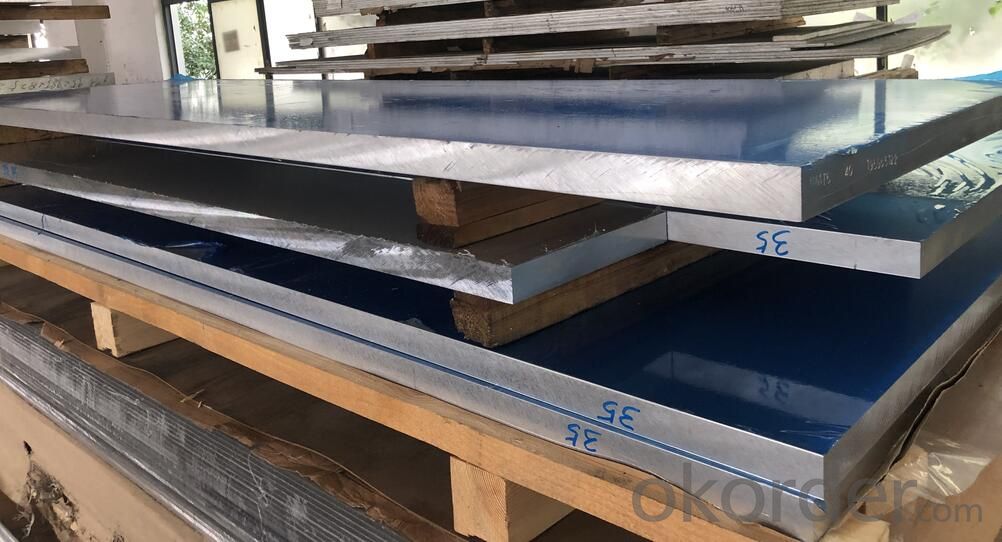

Specifications of automotive aluminum sheet:

| Alloy | 5052, 5754, 6061, 6016, 7075, etc |

| Temper | F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, etc |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 20-2650 |

| Length (mm) | 500-16000 |

| Other | Can be processed by painting, embossing, cutting, patterning, striping, etc. |

Advantages of automotive aluminum sheet:

1. Lightweight: Aluminum alloy materials are light in weight, which helps to reduce the overall weight of the car and improve fuel economy and driving performance.

2. High strength: After proper process treatment, the aluminum sheet can obtain high strength to ensure that the car body maintains structural strength.

3. Good corrosion resistance: Aluminum alloy materials have excellent corrosion resistance and extend the service life of the car.

4. Good formability: Aluminum plates are easy to process into various shapes to meet the design requirements of automobiles.

5. Strong recyclability: Aluminum plates have high recycling value and meet environmental protection requirements.

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- Composite aluminum plate is also called aluminum plastic plate, which is composed of aluminum plastic aluminum three layers, aluminum single board is made of whole aluminum, and aluminum single board is fabricated more than aluminum plastic plate

- Q: how to connect copper pipe and aluminum sheet?

- welding!

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- You have to make it thick, the aluminum IS weak material. or use harder raw material.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling. The first step involves heating a large aluminum ingot to a specific temperature in a furnace. Once the ingot reaches the desired temperature, it is transferred to a rolling mill. In the rolling mill, the heated aluminum ingot is passed between a series of rolling stands. These stands consist of two steel rollers that exert pressure on the aluminum, gradually reducing its thickness. As the ingot passes through each stand, the distance between the rollers is adjusted to achieve the desired thickness. Throughout the rolling process, the aluminum sheet is continuously cooled with water to prevent it from overheating. This also helps to increase its strength and hardness. The cooling process may vary depending on the specific alloy and properties required for the sheet. After the desired thickness is achieved, the aluminum sheet is further processed to enhance its surface finish. This includes processes like annealing, where the sheet is heated and then slowly cooled to relieve any internal stresses and improve its workability. Finally, the aluminum sheet is cut into desired sizes and shapes using shearing or sawing techniques. It can also undergo additional treatments such as coating, painting, or polishing depending on its intended application. Overall, the manufacturing of an aluminum sheet involves heating the ingot, rolling it between sets of steel rollers to reduce its thickness, cooling it, and then further processing to achieve the desired surface finish and size. This process ensures the production of high-quality aluminum sheets that can be used in various industries such as construction, automotive, aerospace, and more.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Indeed, 101 aluminum sheets prove to be fitting for the production of radiators. This particular aluminum alloy, known as 101 aluminum, boasts a pure composition that lends itself to exceptional thermal conductivity, making it a prime choice for radiator utilization. Moreover, its remarkable resistance to corrosion proves pivotal in radiator applications that frequently entail contact with water and other fluids. Furthermore, the lightweight nature and ease of manipulation of 101 aluminum sheets facilitate efficient processes for radiator manufacturing. In summary, the desired properties and characteristics essential for the creation of radiators are duly satisfied by 101 aluminum sheets.

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to follow certain safety precautions to ensure your well-being and minimize the risk of accidents or injuries. Here are some safety measures that should be taken into consideration: 1. Personal Protective Equipment (PPE): Wear appropriate PPE such as safety glasses, gloves, and a long-sleeved shirt to protect yourself from potential hazards. Aluminum shavings can be sharp and can cause injuries if they come into contact with your skin. 2. Ventilation: Work in a well-ventilated area or use local exhaust ventilation systems to prevent the accumulation of fumes and dust. Aluminum dust or fumes can be harmful if inhaled in large quantities. 3. Fire safety: Aluminum is highly flammable, so it is crucial to keep flammable materials away from the work area. Have a fire extinguisher readily available and know how to use it in case of any fire emergencies. 4. Tool safety: Ensure that all tools and equipment used for cutting, bending, or shaping aluminum are in good working condition. Dull or damaged tools can increase the risk of accidents. Follow proper tool handling techniques and avoid using excessive force to prevent injuries. 5. Proper handling: When moving or lifting aluminum sheets, use proper lifting techniques and seek assistance if necessary. Aluminum sheets can be heavy and can cause strains or muscle injuries if not handled properly. 6. Electrical safety: If electrical tools or equipment are used, make sure they are properly grounded and in good working condition. Avoid using damaged or frayed cords and keep them away from any water sources. 7. Storage: Store aluminum sheets in a designated area, away from any heat sources or flammable materials. Properly stack and secure the sheets to prevent them from falling or causing any hazards. 8. First Aid: Have a first aid kit available in case of any minor injuries. Familiarize yourself with the appropriate first aid procedures for cuts, burns, or any other potential injuries that may occur while working with aluminum sheets. By following these safety precautions, you can ensure a safe working environment and minimize the risks associated with handling aluminum sheets. Remember to always prioritize your safety and the safety of those around you.

Send your message to us

Lightweight Aluminum Sheet for Automobile Skin 5052-H32 5754 6061 7075

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords