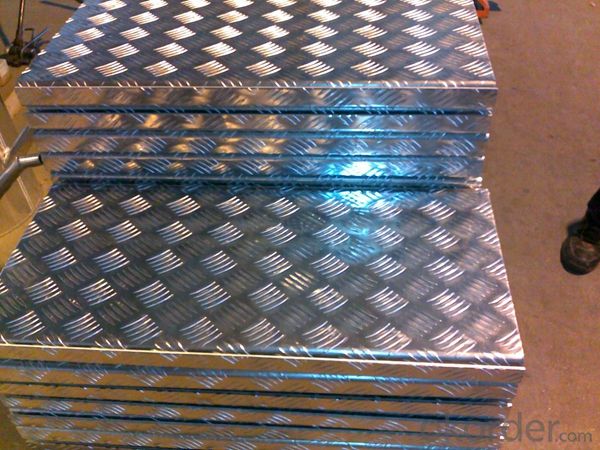

Diamond Plate Aluminum Sheets 4x8x1/4 Mill Finish Five Bar Checkered

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Five Bar Checkered Aluminum Sheet

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Five Bar Checkered Aluminum Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Five Bar Checkered Aluminum Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Mill Finish Five Bar Checkered Aluminum Sheet

6. Package and shipping of Mill Finish Five Bar Checkered Aluminum Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Most, if not all parents go through this torment. You're damned if you do, you're damned if you don't! With our son, I felt uncomfortable with letting him have more than one at a time (on the current schedule in UK, they have 3 at a time on one appointment!). We've split them up now so he only has one every 4-5 weeks. I did lots of reading and found that most problems occur after several doses, this way we'll know if he has any type of reaction to any particular vaccination and he won't have the next doses. So far he's been fine. We also gave him a small amount of sugar water before his most recent vaccination as studies have shown it helps babies deal with stress. It made a huge difference and he barely cried. Have some infant Calpol/Tylenol ready at home to give him if he has a fever or is irritable and just watch him... and only allow him to have the vaccinations you believe are necessary and that you're comfortable with.

- Q: Are aluminum sheets suitable for electrical bus bars?

- Certain applications may find aluminum sheets suitable for use in electrical bus bars. Aluminum possesses several properties that make it a viable choice for bus bars. Firstly, aluminum is a lightweight material, which can be advantageous in situations where weight reduction is crucial. Furthermore, aluminum exhibits good electrical conductivity, although it falls short of copper in terms of conductivity. Nevertheless, aluminum bus bars can still handle high electrical currents and are commonly employed in power distribution systems. However, one drawback of aluminum bus bars is their higher resistance compared to copper bus bars. Consequently, they have a tendency to generate more heat, particularly under heavy current loads. To address this issue, aluminum bus bars are often designed with larger cross-sectional areas to minimize resistance and dissipate heat more effectively. Another challenge associated with aluminum bus bars is their vulnerability to oxidation and corrosion. This concern can be tackled by applying protective coatings or utilizing alloys that offer superior corrosion resistance. Additionally, it is crucial to ensure proper insulation and avoid contact with dissimilar metals to prevent galvanic corrosion. In conclusion, aluminum sheets can serve as suitable materials for electrical bus bars, particularly in scenarios where weight reduction is a priority. However, careful consideration must be given to factors such as electrical conductivity, heat dissipation, and corrosion resistance to ensure optimal performance and longevity of the bus bars.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: This question asks for methods to determine the reliability of a supplier for aluminum sheets.

- <p>To determine if your supplier is reliable for supplying aluminum sheets, consider the following: Check their track record and customer reviews for consistency and quality. Assess their industry certifications, such as ISO standards, which indicate commitment to quality management. Evaluate their supply chain transparency and their ability to meet delivery timelines. Look into their financial stability to ensure they can sustain operations. Request samples to test the quality of their aluminum sheets. Finally, communicate openly with them to gauge their responsiveness and professionalism.</p>

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is lightweight, strong, and has excellent corrosion resistance, making it an ideal material for various automotive components such as body panels, hoods, doors, and engine parts.

- Q: Does exposure to weather conditions have an impact on the durability and integrity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to weathering, thanks to a protective oxide layer that forms on the surface when exposed to air. This layer prevents further oxidation and corrosion, making aluminum durable even in harsh weather conditions. However, the rate of weathering can be influenced by factors such as pollution, temperature fluctuations, and the presence of aggressive chemicals. While aluminum maintains its structural integrity well, it may experience some surface changes like patina formation over time, but these are mostly cosmetic and do not compromise the material's performance significantly.</p>

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Are the aluminum sheets recyclable?

- Yes, aluminum sheets are highly recyclable. Aluminum is one of the most recyclable materials on the planet, and it can be recycled indefinitely without losing its quality. Recycling aluminum sheets requires less energy compared to producing new aluminum from raw materials, which has significant environmental benefits. The recycling process involves melting down the aluminum sheets to extract the metal, which can then be used to produce new aluminum products. Recycling aluminum sheets not only conserves valuable resources but also helps reduce greenhouse gas emissions and landfill waste. Therefore, it is highly recommended to recycle aluminum sheets whenever possible.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Diamond Plate Aluminum Sheets 4x8x1/4 Mill Finish Five Bar Checkered

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords