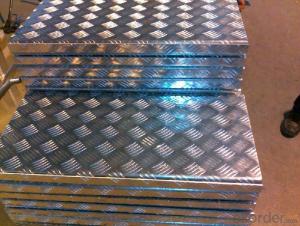

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Alloy | AA1xxx(1050,1060,1070,1100 etc.) |

AA3xxx(3003,3004,3005,3105 etc.) | |

AA5xxx(5005,5052,5083,5754 etc.) | |

Temper | H14,H16,H18,H22,H24,H26,H32 |

Thickness | 0.2-20mm |

Width | 10mm-1500mm |

Embossed | Diamond, Stucco, Three/Five Bars |

Standard | GB/T3880-2012,EN485, ASTM B209 |

Application | Anti-Skid Floor, Decoration Floor etc |

Special specification or color is available as per customers’ requirement | |

2. Usage/Application of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

The embossed aluminum coil/sheet are widely used for decorative purpose in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packaging & Delivery of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Seaworthy package, plastic bag covered inside, carton wrapped outside, paper core, on the wooden pallet. Pallet weight: 2000-25000KG.

4. Production Flow of Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

Melting-Rolling- Cutting- Annealing--Packing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines. Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC.

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Specific storage requirements exist for 101 aluminum sheets. To prevent moisture absorption and corrosion, aluminum sheets must be stored in a clean and dry area. Furthermore, a well-ventilated space is necessary to prevent the accumulation of potentially harmful gases. Proper stacking, with sufficient support and spacing, is crucial to prevent bending or deformation. Moreover, to avoid discoloration or fading, it is essential to shield the sheets from direct sunlight. A recommended practice is covering them with a suitable material, such as a plastic sheet or tarp, to offer an additional layer of protection. Ensuring appropriate storage conditions will uphold the quality and integrity of the aluminum sheets for their intended purpose.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- Do you fold it with aluminium plate? It should be about the same. The cold rolled aluminum of the 1 series is still a little bit stronger,I understand the shape of the material, and if the aluminum extrusion molding, direct use of 6063 is the most appropriate.

- Q: What are the different types of surface treatments available for painted aluminum sheets?

- Painted aluminum sheets can undergo a variety of surface treatments to enhance their appearance, durability, and protection against corrosion and damage. Anodizing is a commonly used surface treatment where aluminum sheets are immersed in an electrolytic solution and an electric current is passed through them. This process forms a protective oxide layer on the surface, improving corrosion resistance and providing a base for painting or other decorative finishes. Another popular treatment is powder coating, which involves applying a dry powder to the aluminum's surface and then heating it to create a tough, protective layer. This coating is known for its durability, resistance to fading and chipping, and ability to offer a wide range of colors and finishes. Apart from anodizing and powder coating, there are other surface treatments available for painted aluminum sheets. Chemical conversion coating entails applying a chemical solution to create a protective layer, while laminate coatings involve adding a thin film or laminate for additional protection and decoration. In conclusion, the various surface treatments for painted aluminum sheets provide several advantages, such as improved appearance, durability, and corrosion resistance. The choice of treatment depends on the specific requirements and desired outcomes for the aluminum sheets.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: What are the common thicknesses of aluminum sheets used in aerospace applications?

- In aerospace applications, aluminum sheets are commonly used due to their lightweight and high strength properties. The thickness of aluminum sheets used in aerospace applications can vary depending on the specific requirements of the component or structure being fabricated. Commonly used thicknesses for aluminum sheets in aerospace applications range from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm). These thicknesses are selected based on factors such as the desired strength-to-weight ratio, structural integrity, and the specific application or component being manufactured. Thinner aluminum sheets, such as those with a thickness of 0.016 to 0.040 inches, are often used for lightweight structures, interior components, and non-critical parts. These thinner sheets provide the necessary strength while minimizing weight. For more structural components, thicker aluminum sheets are employed. Thicknesses between 0.040 and 0.125 inches are commonly used for structural elements like floor panels, bulkheads, and wing ribs. These sheets offer increased strength and rigidity for supporting the aircraft's weight and managing the stresses experienced during flight. In certain cases, even thicker aluminum sheets may be used, ranging from 0.125 to 0.25 inches, for heavy-duty structural components or areas where additional strength is required. These thicker sheets are utilized in critical parts such as landing gear components, wing spars, and engine mounts to ensure the necessary structural integrity and load-bearing capability. It is important to note that these are general ranges, and the specific thickness requirements may vary depending on the aircraft type, design specifications, and the particular application within the aerospace industry.

- Q: What are the different surface patterns or textures available for aluminum sheets?

- There are several different surface patterns and textures available for aluminum sheets, each designed to serve specific purposes and provide unique aesthetic appeal. Some of the most common surface patterns or textures for aluminum sheets include: 1. Smooth: Smooth aluminum sheets have a flat and polished surface without any visible patterns or textures. This type of finish is often used for applications where a clean and sleek appearance is desired, such as architectural elements or interior design. 2. Diamond Plate: Diamond plate aluminum sheets feature a raised diamond pattern on the surface, which provides excellent traction and slip resistance. This texture is commonly used for flooring, stairs, ramps, and industrial applications where grip and durability are essential. 3. Brushed: Brushed aluminum sheets have a consistent linear pattern created by brushing the surface with fine abrasive pads. This finish gives a satin-like appearance, making it popular for decorative purposes like signs, furniture, appliances, and automotive trim. 4. Stucco: Stucco textured aluminum sheets have a raised pattern resembling a stucco wall finish. This texture is achieved by embossing the sheet with a stucco roller, creating a rough and durable surface. Stucco patterned sheets are commonly used for exterior cladding, roofing, and decorative applications. 5. Hammered: Hammered aluminum sheets have a unique texture that resembles the surface of hammered metal. This finish is achieved by imprinting the sheet with a pattern of small indentations using a hammer or similar tool. Hammered sheets are often used for decorative purposes, such as backsplashes, countertops, and art installations. 6. Perforated: Perforated aluminum sheets have a pattern of small holes punched into the surface, allowing for airflow, light transmission, and sound absorption. This texture is commonly used for architectural elements, screens, filters, and ventilation systems. These are just a few examples of the surface patterns and textures available for aluminum sheets. Each texture serves a specific purpose and provides distinct visual appeal, allowing for a wide range of applications in various industries.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures. Aluminum is known for its low density and high strength-to-weight ratio, making it an ideal material for lightweight applications. Aluminum sheets are commonly used in industries such as aerospace, automotive, and construction, where weight reduction is crucial. They offer excellent corrosion resistance, durability, and formability, allowing for easy fabrication and installation. Additionally, aluminum sheets can be easily joined using various welding and adhesive techniques, further enhancing their suitability for lightweight structures.

- Q: Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

Send your message to us

Two Bars Pattern Embossed Aluminum Checkered Anti-Slip Coated Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords