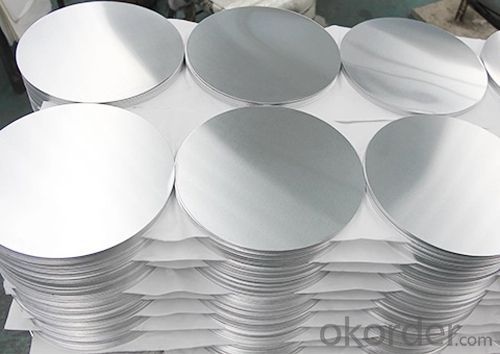

Sheets of Diamond Plate Aluminum - Aluminum Discs for Cookware 1050 1060 3003 for Non-Stick Pans Wholesale

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The lightness and excellent thermal conductivity of aluminum alloy make it a high-quality material for making cookware, especially suitable for cooking environments that require rapid heating and uniform heat distribution, such as outdoor cooking or home use. Aluminum alloys such as 1050, 1060, and 3003 are usually used . It is an excellent choice for manufacturing cookware due to its thermal conductivity, lightweight durability, food safety, ease of processing and cost-effectiveness.

Specifications of aluminum discs for cookware:

| Alloy | 1050, 1060, 1070, 1100, 3003, 3004, 3105, 3A21, 5005, 5052, 5083, 5182, etc. |

| Temper | O, H12, H14, H18, H24, H32, etc. |

| Thickness | 0.2-10mm |

| Width | 50-1600mm |

| Process | hot rolling (DC) or cold rolling (CC) |

| Surface Treatment | Polished |

| Surface | Hairline, Oxidation, Mirror, Embossed, etc |

| Appearance | The surface is smooth and clean, without scratches, whole parts, oil stains or oxidation; the cutting edge has no burrs. Package seaworthy wooden pallet, wooden box, aluminum crate |

| Usage | Suitable for aluminum cookware, pots, pans, frying pans, rice cookers non-stick, pressure cooker soup pots, pizza trays, kettles, fryers, baking sheets, traffic signs, light reflectors, etc. |

Characteristics of aluminum discs for cookware:

1. High thermal conductivity: Aluminum can dissipate heat evenly and quickly. This ensures food cooks evenly and prevents burning or overheating.

2. Lightweight: Aluminum is lightweight compared to other metals used in cookware manufacturing, such as cast iron or stainless steel. This makes aluminum cookware easy to handle and operate, especially for tasks that require frequent stirring or turning.

3. Safety and hygiene: It is safe for food contact and will not release harmful substances into food during the cooking process, ensuring the safety of the final dish.

4. Corrosion resistance: Aluminum disc 1050 has good corrosion resistance, which is very important for cookware exposed to moisture, acid and other food ingredients. Proper care and maintenance can further extend its lifespan.

5. Excellent formability: Aluminum is highly formable, allowing manufacturers to shape it into a variety of cookware designs, including pots, pans and trays. This versatility enables the production of cookware in different sizes, shapes and functions to meet consumer demands.

6. Affordable: Aluminum is low-cost compared to other materials used in cookware production, and its relatively low cost makes it an attractive option for both manufacturers and consumers.

Looking forward to hearing from you!sales @ alummc.com

- Q: Are the aluminum sheets suitable for manufacturing lighting fixtures?

- Yes, aluminum sheets are suitable for manufacturing lighting fixtures. Aluminum is a lightweight and versatile material that offers several advantages for lighting fixture manufacturing. Firstly, aluminum is known for its excellent thermal conductivity, meaning it can effectively dissipate heat generated by the lighting components. This helps in prolonging the lifespan of the lighting fixtures and maintaining their efficiency. Additionally, aluminum is corrosion-resistant, which is crucial for lighting fixtures as they are often exposed to different environmental elements. This property ensures that the fixtures will not degrade over time and can withstand outdoor conditions. Moreover, aluminum sheets can be easily formed into various shapes and sizes, allowing manufacturers to create customized designs for lighting fixtures. This versatility makes aluminum an ideal choice for both functional and aesthetic lighting applications. Furthermore, aluminum is a sustainable and eco-friendly material. It is recyclable, reducing the environmental impact of manufacturing processes. This makes aluminum sheets a popular choice for manufacturers that prioritize sustainability in their operations. Overall, the excellent thermal conductivity, corrosion resistance, versatility, and sustainability of aluminum sheets make them highly suitable for manufacturing lighting fixtures.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q: What are the standards and certifications available for aluminum sheets?

- Aluminum sheets can be evaluated for quality and compliance with industry requirements through various standards and certifications. Some well-known ones include: 1. ASTM International Standards: Developed by the American Society for Testing and Materials (ASTM), these standards focus on aspects like chemical composition, mechanical properties, and dimensional tolerances. They promote consistent quality across different aluminum sheet products. 2. ISO 9001: This globally recognized certification establishes guidelines for quality management systems. Aluminum sheet manufacturers with ISO 9001 certification demonstrate their commitment to meeting customer requirements, continuous improvement, and strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has established a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency in the European market. 6. RoHS Compliance: Compliance with the Restriction of Hazardous Substances (RoHS) is crucial for aluminum sheets used in electrical and electronic equipment. This certification guarantees that the aluminum sheets are free from hazardous substances, ensuring environmental safety. Manufacturers and suppliers of aluminum sheets must adhere to these standards and certifications to ensure their products are of the highest quality, safety, and suitability for specific applications.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet strongly influences its mechanical properties. The mechanical properties of aluminum sheet can include tensile strength, yield strength, elongation, hardness, and fatigue strength, among others. Firstly, the alloy composition affects the overall strength of the aluminum sheet. Aluminum alloys are typically mixed with other elements such as copper, manganese, magnesium, and silicon to enhance their mechanical properties. These alloying elements form solid solutions or precipitates within the aluminum matrix, which can significantly increase the strength of the material. For example, adding copper to aluminum forms a solid solution that increases the tensile strength and yield strength of the sheet. Secondly, the alloy composition affects the ductility and formability of the aluminum sheet. Some alloying elements, such as magnesium and silicon, can reduce the ductility of aluminum alloys. This reduction in ductility can make the sheet more prone to cracking or fracturing under stress. On the other hand, certain alloying elements can improve the formability of aluminum sheet, making it easier to shape or bend without cracking. Furthermore, the alloy composition also influences the resistance to corrosion and heat of aluminum sheet. For instance, aluminum alloys with a high content of magnesium, such as the 5000 series, exhibit excellent resistance to corrosion and are commonly used in marine applications. Additionally, some aluminum alloys are developed specifically for high-temperature applications, with alloying elements like copper and zinc enhancing their heat resistance. Lastly, the alloy composition of aluminum sheet affects its microstructure, which in turn affects its mechanical properties. Different alloy compositions can result in different microstructures, such as grain size, grain boundaries, and phase distribution. These microstructural features can affect the strength, hardness, and fatigue resistance of the aluminum sheet. In conclusion, the alloy composition plays a crucial role in determining the mechanical properties of aluminum sheet. By carefully selecting the appropriate alloy composition, manufacturers can tailor the sheet's properties to meet specific requirements, such as strength, ductility, formability, corrosion resistance, and heat resistance.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets, when compared to steel sheets, are significantly lighter in weight. This is because aluminum has a lower density than steel, making it a more lightweight and versatile material. The specific weight difference between aluminum and steel sheets will depend on the thickness and dimensions of the sheets. However, generally speaking, aluminum sheets can weigh about 1/3 less than steel sheets of the same size. This makes aluminum sheets an ideal choice in applications where weight is a critical factor, such as in the aerospace industry or for lightweight structures.

- Q: How do aluminum sheets perform in extreme weather conditions?

- Aluminum sheets are renowned for their exceptional performance in extreme weather conditions, as they possess inherent properties that render them highly resistant to corrosion and capable of enduring harsh environmental elements like rain, snow, and extreme temperature fluctuations. When confronted with hot weather, aluminum sheets possess the ability to reflect sunlight and dispel heat, thereby averting any warping or deformation. This characteristic renders them suitable for utilization in regions characterized by high temperatures or direct exposure to sunlight. Similarly, in cold weather, aluminum sheets retain their strength and do not become brittle, making them dependable in freezing temperatures or regions prone to heavy snowfall. With a low coefficient of thermal expansion, they can withstand contraction and expansion without any detrimental effects such as cracking or damage. Moreover, aluminum sheets exhibit excellent resistance to moisture, which safeguards them against rusting or corroding when exposed to rain or high levels of humidity. This quality makes them an ideal choice for employment in coastal areas or regions with substantial rainfall. Additionally, aluminum sheets possess the advantage of being lightweight yet durable, enabling them to withstand high winds and severe storms without compromising their structural integrity. This quality positions them as the preferred option for applications such as roofing, siding, and outdoor signage in areas susceptible to hurricanes or strong winds. All in all, aluminum sheets display remarkable performance in extreme weather conditions, which establishes them as a reliable and versatile material for various outdoor applications.

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum has a density of 2.702 g/cm^3. 83 g x (1 cm^3 / 2.702 g) = 30.7 cm^3 That's the volume of the Al sphere. The formula for the volume of a sphere is V = (4/3)(pi)(r^3) where r is the radius. 30.7 = (4/3)(3.1416)((r^3) 7.33 = r^3 1.94 cm = r 1.94 cm x (1 in / 2.54 cm) = 0.76 inches.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, thickness less than 5, cutting edge without burr, not melt.

- Q: The user is asking if it's possible to substitute recycled aluminum sheets for new ones in a project or application.

- <p>Yes, you can use recycled aluminum sheets instead of new ones in many applications. Recycled aluminum maintains the same properties as new aluminum, making it suitable for construction, manufacturing, and various other uses. It's also more sustainable and cost-effective. However, it's important to ensure that the recycled aluminum meets the required specifications and quality standards for your specific project to avoid any structural or performance issues.</p>

- Q: Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is a highly efficient conductor of heat, making it an ideal material for heat exchangers. Its high thermal conductivity allows for excellent heat transfer between fluids, resulting in efficient heat exchange. Additionally, aluminum sheets are lightweight, corrosion-resistant, and have good mechanical properties, further contributing to their suitability for heat exchanger applications.

Send your message to us

Sheets of Diamond Plate Aluminum - Aluminum Discs for Cookware 1050 1060 3003 for Non-Stick Pans Wholesale

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords