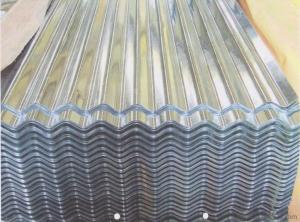

Top Quality Deep Corrugated Aluminum Sheets & Plates for Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium plates are flat sheets made from aluminium, commonly used in various industries such as construction, automotive, aerospace, and manufacturing. They are valued for their lightweight nature, corrosion resistance, and versatility in applications ranging from structural components to decorative finishes.

Advantages:

Lightweight and easy to handle, facilitating transportation and installation.

Excellent corrosion resistance, suitable for outdoor and marine environments.

High strength-to-weight ratio, providing structural integrity while reducing overall weight.

Recyclable material, contributing to sustainable practices and reducing environmental impact.

Versatility in applications, from structural support to decorative purposes, due to its formability and aesthetic appeal.

- Q: Can 101 aluminum sheets be embossed or textured?

- Yes, 101 aluminum sheets can be embossed or textured. Aluminum is a versatile material that can be easily manipulated and shaped. Embossing or texturing aluminum sheets involves applying pressure or heat to create raised or recessed patterns on the surface. This process can be done with various techniques, such as mechanical embossing or chemical etching. As long as the aluminum sheets are of good quality and thickness, they can be embossed or textured to achieve desired designs and patterns.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

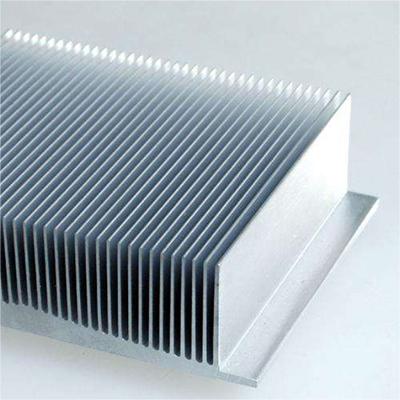

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Certainly, HVAC systems can utilize 101 aluminum sheets. Due to its exceptional thermal conductivity, resistance to corrosion, and lightweight attributes, aluminum is frequently employed in HVAC systems. The 101 aluminum alloy, a widely utilized grade, offers commendable strength and ductility, rendering it suitable for HVAC applications. It is commonly employed in the manufacturing of ducts, air handlers, heat exchangers, and various other components within HVAC systems. Moreover, aluminum sheets are highly malleable, allowing them to be easily molded and shaped in accordance with the specific demands of the HVAC system.

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: What are the different methods of surface printing aluminum sheets?

- Aluminum sheets can be surface printed using various methods, each with its own advantages and applications. Some commonly used techniques include: 1. Screen Printing: This technique involves using a mesh screen with a stencil to transfer ink onto the aluminum sheet. It offers precise printing and vibrant colors, making it suitable for signage, labels, and decorative purposes. 2. Digital Printing: Advancements in technology have made digital printing popular for aluminum sheet printing. It directly prints the design onto the sheet using inkjet technology, offering high detail and a wide range of colors for customized and complex designs. 3. Offset Printing: This versatile method transfers the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. It provides consistent and accurate printing results, often used for packaging, labels, and large-scale printing. 4. Flexographic Printing: This cost-effective method uses flexible relief plates to press the desired design onto flexible materials like aluminum sheets. It is suitable for large-scale production and commonly used for packaging materials and labels. 5. Gravure Printing: Also known as rotogravure printing, this method uses engraved cylinders to transfer ink onto the aluminum sheet. It is known for its high quality and ability to reproduce fine details, often used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: Although not a printing method, embossing is a popular technique for creating raised designs on aluminum sheets. It can be done mechanically or through heat processes, resulting in a three-dimensional effect. Embossed aluminum sheets are used for decorative purposes, architectural applications, or to enhance surface grip. These are just a few of the methods available for surface printing aluminum sheets. The choice of method depends on factors such as design requirements, level of detail, quantity, budget, and intended application.

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- You have thought about it carefully, you can't use aluminum foil.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Musical instruments can indeed be manufactured using aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages in instrument manufacturing. Its exceptional sound transmission properties are well-known, making it ideal for producing resonant and lively tones in musical instruments. Furthermore, aluminum boasts high durability and resistance to corrosion, ensuring the longevity of the instruments. Aluminum sheets are frequently used in the production of percussion instruments such as cymbals and bells due to their ability to generate clear and melodious sounds. Additionally, aluminum can be easily shaped and formed into different components, making it a popular choice for constructing brass instruments like trumpets and trombones. In conclusion, aluminum sheets are a viable and successful option in the manufacturing of musical instruments.

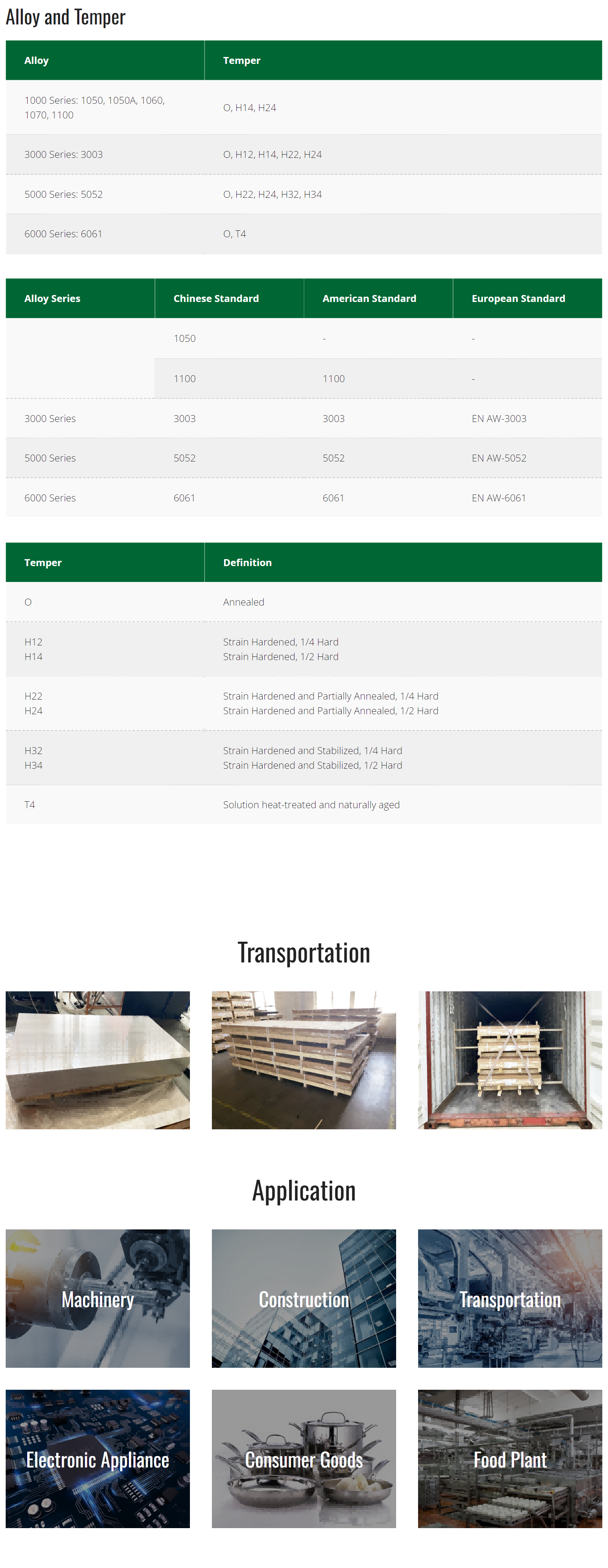

- Q: This question asks about the various grades of aluminum sheets and the impact of these grades on their pricing.

- <p>Aluminum sheets are categorized into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicate alloys). Each grade has unique characteristics affecting their applications, such as corrosion resistance, strength, and formability. The price of aluminum sheets varies with the grade due to differences in purity, alloying elements, production complexity, and market demand. Purity and the addition of alloying elements can increase the cost, while the availability and demand in the market also influence pricing. For instance, 1000 series sheets are generally cheaper due to their high purity and lack of alloying, while 6000 series sheets, known for their strength and durability, command a higher price.</p>

- Q: Can 101 aluminum sheets be anodized for outdoor architectural applications?

- Indeed, it is possible to anodize 101 aluminum sheets for outdoor architectural purposes. Anodizing, a procedure that enhances aluminum's protective layer, grants it increased resistance against corrosion and deterioration. This technique is frequently employed in architectural applications to safeguard aluminum from outdoor elements. By subjecting the 101 aluminum sheets to anodization, they can be rendered sturdier and better suited for outdoor utilization, guaranteeing their long-lasting appearance and performance.

Send your message to us

Top Quality Deep Corrugated Aluminum Sheets & Plates for Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords