Diamond Plate Aluminum Sheets 4x8 - Embossed 5005 Alloy Automotive Grade China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Embossed Aluminium Sheet 5005 Alloy for Automotive China Supply

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Embossed Aluminium Sheet 5005 Alloy for Automotive China Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Embossed Aluminium Sheet 5005 Alloy for Automotive China Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

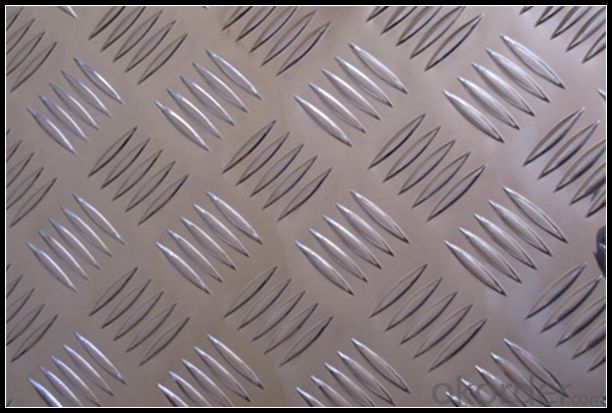

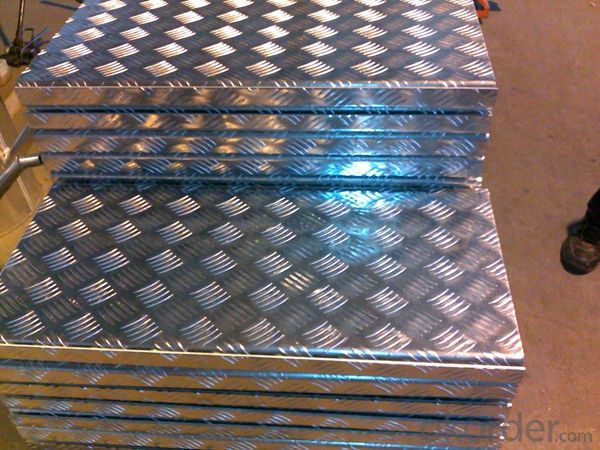

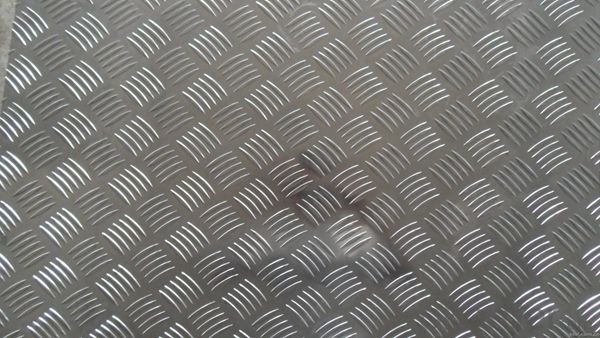

5. Image of Embossed Aluminium Sheet 5005 Alloy for Automotive China Supply

6. Package and shipping of Embossed Aluminium Sheet 5005 Alloy for Automotive China Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Dear all, i'm having crack problem with bending aluminium sheet metal, anyone know than which type(Model) of aluminium sheet metal is suitable for bending, Thanks.

- All aluminum can be bent if u have the right equipment. I have no idea what you are using it for, so I can't give you specific advice. But, go with the lightest gauge aluminum that fits your purpose. The higher the gauge number, the thinner the aluminum is. 16 gauge aluminum is 1/16 thick, for example, but 18 gauge is thinner. Also, the temper of the material affects how easy it is to bend. 6063 aluminum is more malleable (easier to bend) than 6061.

- Q: Can aluminum sheets be used for heat dissipation?

- Indeed, heat dissipation can be achieved by employing aluminum sheets. Renowned for its outstanding thermal conductivity, aluminum effectively conducts heat away from its origin, rendering it highly sought-after in numerous industries for heat sinks and heat exchangers. By molding and shaping aluminum sheets into diverse arrangements, surface area can be maximized, thereby augmenting heat dissipation. Additionally, the lightweight and corrosion-resistant characteristics of aluminum render it a favored material for applications involving heat dissipation.

- Q: I'm working on this project and I have to glue together a 4mm thick aluminum and a 5mm aluminum. It's a 17mm wide hexagon.

- spotwelder

- Q: What is the electrical conductivity of aluminum sheets?

- The electrical conductivity of aluminum sheets is quite high, making aluminum one of the best conductors of electricity among common metals. It has a conductivity rating of approximately 37.7 x 10^6 siemens per meter (S/m). This high electrical conductivity makes aluminum a preferred choice for various electrical applications, such as wiring, power transmission lines, and electrical connectors.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Certainly, aluminum sheets prove to be a fitting choice for utilization in cryogenic surroundings. With its exceptional thermal conductivity and low density, aluminum emerges as an optimal substance for cryogenic purposes. It can endure exceedingly cold temperatures while maintaining its structural integrity and avoiding noticeable thermal expansion. Moreover, aluminum exhibits commendable resistance against corrosion and can be conveniently fashioned into diverse configurations and sizes. These attributes render aluminum sheets widely employed in cryogenic systems, including cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a lightweight and durable material that offers excellent weather resistance and structural integrity, making it an ideal choice for canopies. It can be easily fabricated into various shapes and sizes, allowing for versatile and aesthetically pleasing designs. Additionally, aluminum can be coated or anodized to enhance its appearance and protect it from corrosion, further enhancing its suitability for architectural canopies.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- The aluminum plate is higher than the stainless steel reflectivity, the focal point, the power, the speed are not the same, the general carbon dioxide laser does not have the anti - reflection lens, then had better not cut the aluminum plate, easy to burn the laser internal lens.

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: Can aluminum sheets be used for chemical reactors?

- Certain applications allow for the use of aluminum sheets in chemical reactors. Aluminum possesses excellent corrosion resistance, rendering it appropriate for diverse chemical reactions. Nevertheless, it is crucial to take into account the nature of the chemicals employed and their potential reactivity with aluminum. In highly acidic or alkaline environments, aluminum's reactivity and susceptibility to corrosion should be duly recognized. Furthermore, specific gases or elevated temperatures may render aluminum unsuitable for reactions. In such instances, alternative materials such as stainless steel or glass-lined reactors might prove more fitting.

Send your message to us

Diamond Plate Aluminum Sheets 4x8 - Embossed 5005 Alloy Automotive Grade China Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords