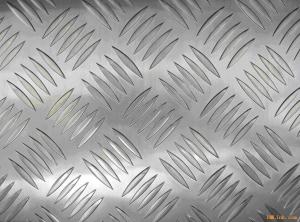

4x8 Aluminum Sheets - Five Bars Diamond Short Delivery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Five Bars,Diamond:

Five Bars,Diamond is widely used for decorative purposes in construction, packing and appliance. Five Bars,Diamond aluminum coil is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of the Aluminum Five Bars,Diamond:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Five Bars,Diamond

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-20mm |

Width: | 30mm-1500mm |

4. Production of Five Bars,Diamond

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- any contractor that does heating and coolin..... or a contruction site in your area

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It is also resistant to harsh weather conditions and pests, making it a popular choice for many homeowners and builders. However, it is important to ensure proper installation to maximize its benefits and longevity.</p>

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet strongly influences its mechanical properties. The mechanical properties of aluminum sheet can include tensile strength, yield strength, elongation, hardness, and fatigue strength, among others. Firstly, the alloy composition affects the overall strength of the aluminum sheet. Aluminum alloys are typically mixed with other elements such as copper, manganese, magnesium, and silicon to enhance their mechanical properties. These alloying elements form solid solutions or precipitates within the aluminum matrix, which can significantly increase the strength of the material. For example, adding copper to aluminum forms a solid solution that increases the tensile strength and yield strength of the sheet. Secondly, the alloy composition affects the ductility and formability of the aluminum sheet. Some alloying elements, such as magnesium and silicon, can reduce the ductility of aluminum alloys. This reduction in ductility can make the sheet more prone to cracking or fracturing under stress. On the other hand, certain alloying elements can improve the formability of aluminum sheet, making it easier to shape or bend without cracking. Furthermore, the alloy composition also influences the resistance to corrosion and heat of aluminum sheet. For instance, aluminum alloys with a high content of magnesium, such as the 5000 series, exhibit excellent resistance to corrosion and are commonly used in marine applications. Additionally, some aluminum alloys are developed specifically for high-temperature applications, with alloying elements like copper and zinc enhancing their heat resistance. Lastly, the alloy composition of aluminum sheet affects its microstructure, which in turn affects its mechanical properties. Different alloy compositions can result in different microstructures, such as grain size, grain boundaries, and phase distribution. These microstructural features can affect the strength, hardness, and fatigue resistance of the aluminum sheet. In conclusion, the alloy composition plays a crucial role in determining the mechanical properties of aluminum sheet. By carefully selecting the appropriate alloy composition, manufacturers can tailor the sheet's properties to meet specific requirements, such as strength, ductility, formability, corrosion resistance, and heat resistance.

- Q: What are the standard thicknesses for aluminum sheets utilized in construction?

- <p>Yes, there are standards for the thickness of aluminum sheets used in construction. These standards vary by country and application. In the United States, the Aluminum Association sets standards, such as AA 3003-H14, which is commonly used in construction for thicknesses ranging from 0.020 to 0.250 inches. In Europe, EN 485-2 covers the specifications for aluminum sheet thicknesses. Thicknesses can range from 0.4mm to 6.0mm, depending on the specific requirements of the construction project. It's important to consult the relevant standards for the region and application to ensure compliance and proper material selection.</p>

- Q: could magnet attract iron with the seperation of rubber and aluminum sheets?

- it does within the range of magnetic force.

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

- Q: Can aluminum sheet be used for solar panels?

- Absolutely! When it comes to solar panels, aluminum sheet is a fantastic choice. Thanks to its remarkable strength, durability, and lightweight nature, aluminum is a widely favored material for constructing these panels. Its versatility shines through as it serves as both the frame and mounting structure, providing unparalleled support and stability. Moreover, its exceptional resistance to corrosion is a crucial factor given the panels' exposure to the elements. On top of all that, aluminum's highly conductive properties allow for efficient electricity transfer from the solar cells within the panel. All in all, incorporating aluminum sheet into solar panel construction significantly enhances their performance, longevity, and overall efficiency.

- Q: Are aluminum sheets suitable for high-temperature applications?

- No, aluminum sheets are not suitable for high-temperature applications as they have a low melting point and tend to lose their strength and become deformed at high temperatures.

Send your message to us

4x8 Aluminum Sheets - Five Bars Diamond Short Delivery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords