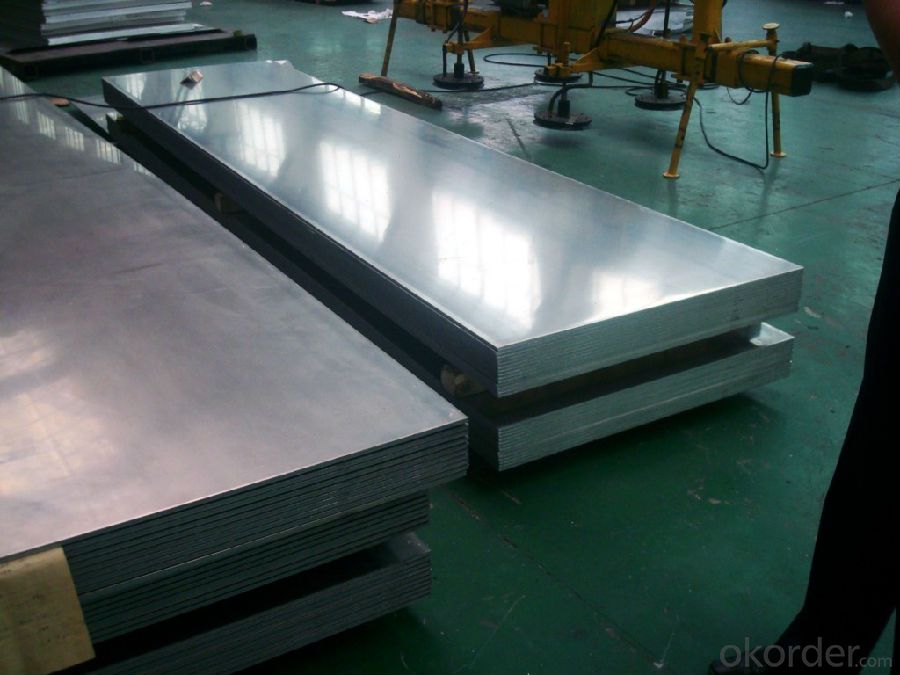

High Quality Embossing Aluminum Diamond Plate Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Embossing Aluminum Plate With High Quality

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of Embossing Aluminum Plate With High Quality

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Can the aluminum sheets be used for manufacturing power transmission lines?

- Power transmission lines can be manufactured using aluminum sheets. Aluminum possesses several properties that make it suitable for this purpose. To begin with, aluminum is a lightweight material, making it more convenient to handle and transport compared to metals like copper. This can lead to reduced installation costs and increased efficiency of the power transmission lines. Additionally, aluminum exhibits good electrical conductivity, although it may not be as conductive as copper. However, due to its lighter weight, aluminum can still achieve similar electrical performance to copper while using less material. This can result in cost savings and reduced energy losses in the transmission lines. Moreover, aluminum demonstrates excellent resistance to corrosion, which is vital for power transmission lines that are frequently exposed to different weather conditions and environmental factors. Aluminum can endure harsh conditions and maintain its structural integrity over time, ensuring the reliability and longevity of the power transmission infrastructure. To conclude, aluminum sheets can indeed be utilized for the manufacturing of power transmission lines due to their lightweight nature, favorable electrical conductivity, and outstanding corrosion resistance.

- Q: What are the different methods of surface printing aluminum sheets?

- Aluminum sheets can be surface printed using various methods, each with its own advantages and applications. Some commonly used techniques include: 1. Screen Printing: This technique involves using a mesh screen with a stencil to transfer ink onto the aluminum sheet. It offers precise printing and vibrant colors, making it suitable for signage, labels, and decorative purposes. 2. Digital Printing: Advancements in technology have made digital printing popular for aluminum sheet printing. It directly prints the design onto the sheet using inkjet technology, offering high detail and a wide range of colors for customized and complex designs. 3. Offset Printing: This versatile method transfers the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. It provides consistent and accurate printing results, often used for packaging, labels, and large-scale printing. 4. Flexographic Printing: This cost-effective method uses flexible relief plates to press the desired design onto flexible materials like aluminum sheets. It is suitable for large-scale production and commonly used for packaging materials and labels. 5. Gravure Printing: Also known as rotogravure printing, this method uses engraved cylinders to transfer ink onto the aluminum sheet. It is known for its high quality and ability to reproduce fine details, often used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: Although not a printing method, embossing is a popular technique for creating raised designs on aluminum sheets. It can be done mechanically or through heat processes, resulting in a three-dimensional effect. Embossed aluminum sheets are used for decorative purposes, architectural applications, or to enhance surface grip. These are just a few of the methods available for surface printing aluminum sheets. The choice of method depends on factors such as design requirements, level of detail, quantity, budget, and intended application.

- Q: What are the dimensions and thickness options for aluminum sheets?

- Depending on specific requirements and applications, the dimensions and thickness options for aluminum sheets can vary. There is a wide range of sizes and thicknesses available to cater to different needs. Concerning dimensions, aluminum sheets come in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. However, these dimensions may vary depending on the supplier and the specific product. The thickness options for aluminum sheets also differ. Thickness is usually measured in gauge, where lower gauge numbers indicate thicker sheets. Aluminum sheets can be obtained in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It is important to note that the specific dimensions and thickness options may vary depending on the supplier and the grade of aluminum being used. It is always advisable to consult with a supplier or manufacturer to obtain precise information about the available dimensions and thickness options for aluminum sheets.

- Q: Can aluminum sheets be used for battery enclosures?

- Indeed, battery enclosures can utilize aluminum sheets. Aluminum proves to be a highly favored material for battery enclosures owing to its remarkable properties. Its lightweight nature, resistance to corrosion, and commendable conductivity render it an appropriate choice for safeguarding batteries and guaranteeing their optimal functionality. Furthermore, the exceptional strength-to-weight ratio of aluminum permits the creation of robust yet lightweight enclosures, making it an ideal selection for diverse battery applications. Moreover, the recyclability of aluminum adds to its appeal as an eco-friendly alternative. In conclusion, aluminum sheets serve as a feasible and frequently employed material for battery enclosures.

- Q: Can aluminum sheet be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheet as a viable option. Aluminum, known for its commendable thermal conductivity attributes, is frequently employed as a material for heat sinks. Its lightweight nature, cost-effectiveness, and resistance to corrosion contribute to its popularity. With the ability to easily mold aluminum sheet into diverse shapes and sizes, it becomes suitable for a range of heat sink designs. The flat and thin composition of aluminum sheet aids in effective heat dissipation by expanding the available surface area for heat transfer. Moreover, aluminum can be readily machined or extruded to produce fins, further enhancing the heat dissipation capabilities of the heat sink. Overall, due to its myriad advantages, aluminum sheet stands as a favored choice for heat sinks in a multitude of applications, encompassing electronics, computers, LED lights, and automotive components.

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: This question asks for a list of various methods used to treat the surface of aluminum sheets to improve their properties or appearance.

- <p>There are several types of surface treatment for aluminum sheets, each serving different purposes. These include: Anodizing, which creates a protective oxide layer and enhances corrosion resistance; Chemical Conversion Coating, such as chromate conversion, to improve paint adhesion and corrosion resistance; Electrolytic Polishing, which provides a smooth, shiny surface; Powder Coating, an electrostatic process that applies a durable coating; Paint Coating, offering a wide range of colors and finishes; and Mechanical Polishing, which smooths the surface and improves reflectivity. Each treatment has its specific applications and benefits, depending on the desired outcome for the aluminum sheet.</p>

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- There are several weight-saving benefits of using aluminum sheets in different applications. Firstly, aluminum is a lightweight metal, with a density much lower than other commonly used materials such as steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in various applications. The reduced weight of aluminum sheets is particularly advantageous in transportation industries. For example, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the vehicle's overall weight. This weight reduction leads to improved fuel efficiency, as less energy is required to move the lighter vehicle. Additionally, lighter vehicles generally have better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every extra kilogram of weight on an aircraft can increase fuel consumption, and thus operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures, such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. Another industry where the weight-saving benefits of aluminum sheets are highly valued is the construction sector. Aluminum sheets are often used in the construction of buildings and infrastructure due to their lightweight nature. This lightweight characteristic not only makes installation easier but also reduces the overall load on the building's foundation. Moreover, using aluminum sheets in construction can also lead to cost savings, as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products, such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. The lightweight nature of aluminum allows for reduced weight in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets offer a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q: Can aluminum sheets be used for structural purposes?

- Indeed, structural purposes can be fulfilled by utilizing aluminum sheets. This material, known for its lightness and remarkable malleability, can be effortlessly shaped and sized in diverse forms. Thanks to its exceptional strength-to-weight ratio, it is an ideal choice for structural applications that prioritize weight reduction. In industries such as aerospace, automotive, and construction, aluminum sheets are commonly employed to create structural components like panels, beams, and frames. Moreover, the corrosion resistance of aluminum adds to its suitability for structural purposes, particularly in outdoor or marine settings. Ultimately, aluminum sheets present a dependable and economical solution for structural applications.

- Q: Can aluminum sheets be waterjet cut?

- Indeed, it is possible to employ waterjet cutting for aluminum sheets. By utilizing a combination of high-pressure water and an abrasive substance, waterjet cutting proves to be an adaptable approach in severing a range of materials, including aluminum and other metals. The efficacy of this technique in cutting aluminum stems from its ability to avoid heat generation, thereby preventing potential distortion or harm to the metal. Moreover, it ensures exceptional precision and accuracy, facilitating the effortless cutting of intricate shapes and designs. Consequently, waterjet cutting has become a prevalent practice in industries necessitating immaculate and precise cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

High Quality Embossing Aluminum Diamond Plate Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords