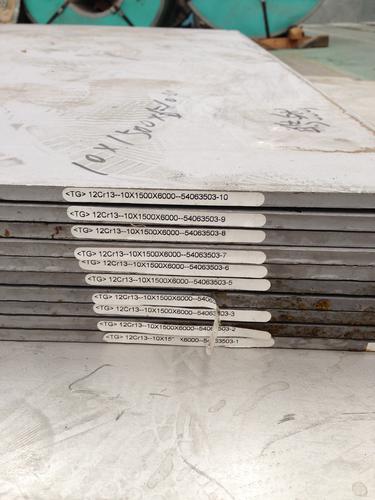

stainless steel plate hot rolled 201

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

grade | 201,301,304,310,316,410,420,430,etc. |

surface | 2B,NO.1, NO.4, Mirror, Hairline, etc. |

thickness | 1MM, |

width | 1200MM,1220MM,1500MM,ETC. |

length | 2400MM,2440MM,3000MM,ETC. |

Payment terms | T/T, or L/C. |

Delivery time | Normally within 1 weeks after get your deposits. |

package | Standard export package, normally with wooden pallets |

MOQ | 5 tons/each size |

We have the best-quality stainless steel sheet/coil,etc.

with the shortest deliverytime, etc.

- Q: What are the different types of stainless steel sheet finishes for marine applications?

- Marine applications commonly employ various types of stainless steel sheet finishes to enhance durability, corrosion resistance, and aesthetic appeal. 1. No. 1 Finish: Generally utilized for structural applications, this rough and non-reflective finish is achieved through hot-rolling. It offers good corrosion resistance and is suitable for marine applications where aesthetics are not a primary concern. 2. No. 2B Finish: Achieved through cold-rolling, annealing, and pickling, this smooth and reflective finish boasts excellent corrosion resistance. It is widely used in marine applications that require a moderate level of aesthetics. 3. No. 4 Finish: This brushed finish features a dull and non-reflective surface. It is obtained by grinding with progressively finer abrasives until the desired appearance is achieved. No. 4 finish is commonly chosen for marine applications where aesthetics play a crucial role, as it provides a clean and uniform look. 4. No. 8 Mirror Finish: Highly reflective, this finish is achieved by polishing with progressively finer abrasives until a mirror-like surface is obtained. No. 8 mirror finish is commonly utilized in marine applications where a high level of aesthetics is desired, as it offers a visually appealing and reflective surface. 5. Satin Finish: This semi-reflective finish is achieved by brushing the stainless steel sheet with a fine abrasive material. Satin finish is often selected for marine applications that require a moderate level of aesthetics, as it provides a clean and visually appealing surface. Apart from these standard finishes, specialized finishes like textured or patterned finishes are available for marine applications to enhance slip resistance. The choice of finish depends on specific requirements, including corrosion resistance, aesthetics, and functionality in the marine application.

- Q: What are the common applications for stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their excellent properties and durability. Some common applications for stainless steel sheets include: 1. Architectural: Stainless steel sheets are often used in architectural applications such as cladding, roofing, and wall panels. They provide a sleek and modern appearance to buildings while also offering corrosion resistance and ease of maintenance. 2. Kitchenware: Stainless steel sheets are widely used in the manufacturing of kitchen appliances, sinks, countertops, and cookware. They are highly resistant to stains, heat, and corrosion, making them ideal for use in a kitchen environment. 3. Automotive: Stainless steel sheets are utilized in the automotive industry for various applications including exhaust systems, body parts, and trim. They provide strength, corrosion resistance, and an attractive finish, making them suitable for both functional and aesthetic purposes. 4. Medical equipment: Stainless steel sheets are commonly used in the production of medical equipment and instruments due to their hygienic properties and resistance to corrosion and staining. They are used in surgical instruments, dental tools, hospital equipment, and implants. 5. Chemical and petrochemical industries: Stainless steel sheets are extensively employed in these industries due to their resistance to high temperatures, chemicals, and corrosion. They are utilized in storage tanks, pipelines, heat exchangers, and other equipment that comes into contact with corrosive substances. 6. Food processing: Stainless steel sheets are highly sought after in the food processing industry due to their hygienic properties and resistance to corrosion. They are used to create food preparation surfaces, storage containers, and machinery that must meet strict sanitary standards. 7. Construction: Stainless steel sheets find applications in construction projects such as bridges, tunnels, and railway tracks due to their strength, durability, and resistance to corrosion. They are also used in the construction of industrial buildings, warehouses, and infrastructure. 8. Aerospace: Stainless steel sheets are utilized in the aerospace industry for various components including aircraft frames, engine parts, and interior fittings. They offer excellent strength-to-weight ratio, corrosion resistance, and heat resistance, making them suitable for demanding aerospace applications. Overall, stainless steel sheets are versatile and widely used in various industries due to their outstanding properties, making them an essential material for many applications.

- Q: What are the benefits of using textured stainless steel sheets in retail displays?

- Using textured stainless steel sheets in retail displays offers several advantages. Firstly, they can give a modern and sleek look to any retail space, attracting customers and setting the store apart from competitors. Secondly, these sheets are highly durable, able to withstand wear and tear and maintain their appearance over time. Additionally, they are easy to clean and maintain, ensuring a high level of hygiene in the store. Moreover, their versatility allows for customization to fit any retail display needs. Lastly, these sheets are environmentally friendly, as stainless steel is recyclable and promotes sustainability. In conclusion, utilizing textured stainless steel sheets in retail displays enhances brand image, creates visually appealing displays, and provides a positive shopping experience for customers.

- Q: What are the benefits of using embossed stainless steel sheets in elevator interiors?

- There are several benefits of using embossed stainless steel sheets in elevator interiors. Firstly, embossed stainless steel sheets add a touch of elegance and sophistication to the overall design of the elevator. The embossed patterns create a visually appealing surface that can enhance the aesthetic appeal of the interior space. This is especially important in commercial buildings and high-end residential complexes where a luxurious ambiance is desired. Secondly, embossed stainless steel sheets are highly durable and resistant to wear and tear. Elevator interiors are subject to constant use and can be prone to scratches, dents, and other damages. The embossed pattern on the stainless steel surface helps to hide minor imperfections, ensuring that the interior maintains its pristine appearance for a longer period of time. Additionally, stainless steel is known for its corrosion resistance, making it a suitable choice for environments with high humidity levels, such as elevator shafts. Furthermore, embossed stainless steel sheets are easy to clean and maintain. Elevator interiors are often exposed to dirt, fingerprints, and other stains. The smooth surface of the embossed stainless steel makes it easy to wipe away these marks, ensuring that the interior always looks clean and well-maintained. This is particularly important in public spaces where cleanliness is essential for creating a positive impression on users. Additionally, embossed stainless steel sheets offer a high level of customization. They can be manufactured in various patterns, textures, and finishes, allowing for endless design possibilities. This enables architects and designers to create unique and personalized elevator interiors that reflect the desired theme or branding of a building. The versatility of embossed stainless steel also makes it easy to match with other interior design elements, such as flooring, lighting fixtures, and wall coverings. In conclusion, the benefits of using embossed stainless steel sheets in elevator interiors include enhanced visual appeal, durability, ease of maintenance, and customization options. These qualities make embossed stainless steel an ideal material for elevators in various settings, from commercial buildings to residential complexes, adding value and elegance to the overall design.

- Q: Can stainless steel sheets be used for roofing or cladding?

- Yes, stainless steel sheets can be used for roofing or cladding as they offer durability, corrosion resistance, and a sleek aesthetic.

- Q: Are stainless steel sheets resistant to staining from food?

- Yes, stainless steel sheets are highly resistant to staining from food. Stainless steel is known for its excellent corrosion resistance and non-reactivity with various substances, including food. It is a popular choice for kitchen appliances and cookware due to its ability to withstand prolonged exposure to food without staining or reacting chemically. Stainless steel sheets are also easy to clean, making them ideal for food preparation areas where cleanliness is essential. Additionally, the smooth and non-porous surface of stainless steel sheets prevents the absorption of food particles and liquids, reducing the risk of staining. Overall, stainless steel sheets provide a durable and stain-resistant option for food-related applications.

- Q: Are stainless steel sheets suitable for outdoor railings?

- Indeed, outdoor railings can be made from stainless steel sheets. Renowned for their resistance to corrosion and remarkable durability, stainless steel sheets are a favored selection for outdoor purposes. Furthermore, they possess the ability to endure adverse weather conditions, such as rain, snow, and UV radiation, without compromising their structural integrity or visual appeal. As a result, stainless steel railings require minimal maintenance and are effortlessly cleaned, rendering them a practical and enduring choice for outdoor areas. In addition to their practicality, stainless steel sheets provide a sleek and contemporary aesthetic, elevating the overall appearance and ambiance of any outdoor railing system.

- Q: What are the different types of punched finishes available for stainless steel sheets?

- There are several different types of punched finishes available for stainless steel sheets, each offering unique characteristics and benefits. Some of the most common punched finishes include: 1. Round Hole: This is the most basic and widely used punched finish. It features evenly spaced round holes that provide good airflow and visibility. It is commonly used in applications such as ventilation systems, decorative panels, and filters. 2. Square Hole: Similar to round hole punched finish, square hole punched finish offers a clean and modern look. It is often preferred when a more geometric pattern is desired. Square hole punched sheets are commonly used in architectural applications, screens, and fencing. 3. Slotted Hole: Slotted hole punched finish is characterized by elongated holes that provide larger openings for increased visibility or improved drainage. It is commonly used in applications such as grilles, sunshades, and safety barriers. 4. Hexagonal Hole: Hexagonal hole punched finish features hexagon-shaped holes that offer a unique and aesthetically pleasing pattern. It is commonly used in decorative applications, such as wall cladding, signage, and artistic installations. 5. Decorative Patterns: In addition to the standard punched finishes, there are various decorative patterns available for stainless steel sheets. These patterns can include custom designs, logos, or intricate shapes, adding a personalized touch to any project. The choice of punched finish depends on the specific requirements of the application, including aesthetics, functionality, and performance. It is important to consider factors such as hole size, open area percentage, strength, and corrosion resistance when selecting the appropriate punched finish for stainless steel sheets.

- Q: Are stainless steel sheets good for chemical processing?

- Yes, stainless steel sheets are ideal for chemical processing due to their exceptional corrosion resistance, high strength, and durability. They can withstand exposure to various chemicals, acids, and alkalis without getting corroded or contaminated, making them an excellent choice for such applications.

- Q: Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength and resistance to corrosion, making it suitable for applications that require high-pressure resistance. Stainless steel sheets can withstand high pressures without deforming or breaking, making them ideal for use in industries such as oil and gas, chemical processing, and power generation, where high-pressure environments are common. Additionally, stainless steel sheets can maintain their structural integrity and performance even at elevated temperatures, further enhancing their suitability for high-pressure applications.

Send your message to us

stainless steel plate hot rolled 201

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords