Selling 0.3-10mm 1100,5052,5083,6082,8011,3003,7075 aluminum sheets factory direct sales

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Our company provides high-quality 1-8 series aluminum sheets, aluminum coils, aluminum foils, patterned sheets, ship sheets, automobile sheets, packaging foils, hydrophilic foils, bottle cap materials, etc. The main features of aluminum sheets are light weight, corrosion resistance, high strength, easy processing, high cost performance, etc. They are widely used in lighting fixtures, building exteriors, furniture, elevators, signboards, refrigerators, aircraft, mechanical parts manufacturing and processing, mold manufacturing, chemical/insulation pipe coating, and high-quality ship sheets.

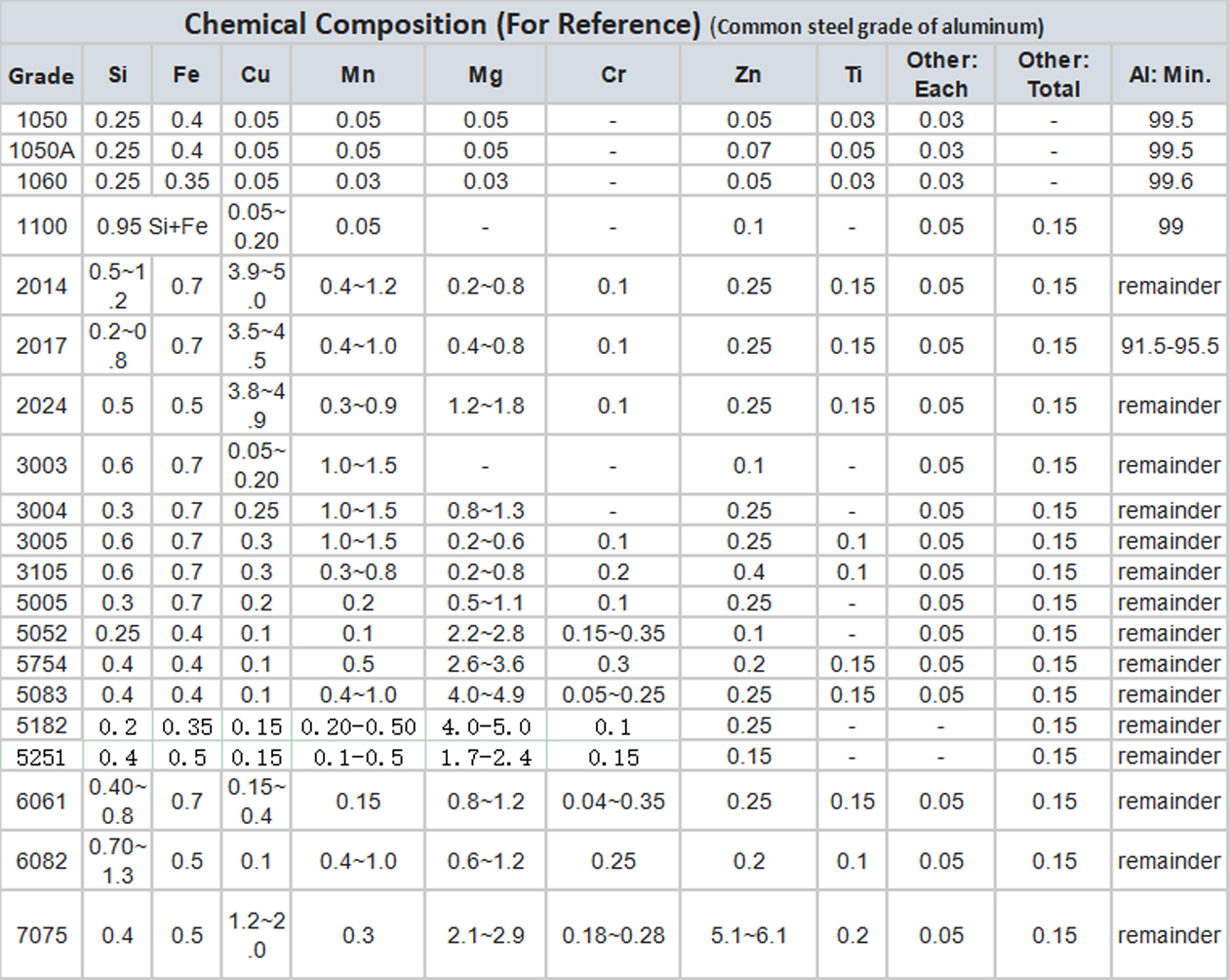

Aluminum sheet specifications:

Alloy: 1050, 1060, 1070, 1100, 1145, 1200, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754, 6061, 7075, 8011, 8021, 8079

State: O, H12, H14, H16, H18, H22, H24, H26, H32, H34, H111, H112, T6, F, T651

Thickness: 0.15~300mm

Width: 500-2500mm

Length: 100-16000mm

Delivery: within 10-20 days from the date of deposit or letter of credit.

Service:Custom-made,Cutting, bending, CNC, anodizing, etc.

Others:Sample and certificates available.

Surface Treatment:Electroplating/Coloring/Drawing/Sandblasting/Polishing

Application:Rail transit, aerospace, machinery and equipment, petrochemical, construction, automotive:aluminum, shipbuilding

Lead Time:Normally 7-15 working days after the receipt of 30% deposit, according to the quantity

Payment Terms:30% TT for deposit,70% TT /70% LC at sight balance before shipment

Price Terms:FOB, EXW, CIF, CFR

Packing:Standard Sea Worthy Package or according to customer's requirements

Advantages of aluminum plate:

1. Easy to process

2. Good electrical and thermal conductivity

3. Low density

4. High strength

5. Good corrosion resistance

6. Price advantage

7. Environmentally friendly and recyclable

8. Wide range of applications

- Q: Are aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant due to the formation of a protective oxide layer on their surface.

- Q: I'm wanting to buy colorguard poles, and I found some good deals on aluminum and fiberglass ones. But what are the pros and cons of each one?

- I'd say fiberglass because... - Durability - Aluminum is a very bendable metal. It dents, it bends, and it breaks easier than any other metal pole you'll find. This is because it's a very low density metal. - Flexibility = more dramatic twirling due to pole flex, and it's less breakable. - Counter Weight = A flag on one side of the pole would be harder to move around swiftly without a counterweight. Thus a heavier pole would entail having a center of gravity on the flag pole closer to the hand, making it easier to maneuver the flag, but the pole would be harder to lift as a whole. I'm no expert on colorguard poles, though. Fiberglass has come a long way. While aluminum is always the same material, fiberglass is a constantly evolving building material.

- Q: Is aluminum sheet fire-resistant?

- Aluminum sheet is not inherently fire-resistant, but it does have certain properties that make it more fire-resistant than other materials. Aluminum has a high melting point, which means it can withstand high temperatures without melting or catching fire. Additionally, aluminum has a low thermal conductivity, meaning it does not easily transfer heat. This makes it more difficult for fire to spread across an aluminum sheet. However, it is important to note that aluminum can still be affected by fire. When exposed to extreme heat, aluminum can weaken and lose its structural integrity. It can also become more susceptible to burning if exposed to certain chemicals or intense flames. To enhance the fire resistance of aluminum sheet, it can be coated with fire-retardant materials or treated with fire-resistant coatings. These additional measures can help to further reduce the risk of fire and improve the overall fire performance of the aluminum sheet. In summary, while aluminum sheet is not completely fire-resistant, it does possess certain characteristics that make it more resistant to fire than other materials. However, it is crucial to take appropriate precautions and use additional fire-resistant treatments when necessary to ensure maximum safety.

- Q: Can aluminum sheets replace traditional roofing materials such as wood or metal?

- <p>Yes, aluminum sheets can be used as an alternative to traditional wooden or metal roofing. They offer several advantages, including resistance to corrosion, lightweight nature, and durability. Aluminum is also recyclable and can be painted or coated to provide a long-lasting finish. However, it's important to consider factors such as cost, local climate, and the specific requirements of the building project when deciding whether to use aluminum sheets for roofing.</p>

- Q: Are the aluminum sheets suitable for manufacturing electrical busbars?

- Yes, aluminum sheets are suitable for manufacturing electrical busbars. Aluminum is a popular choice for busbars due to its excellent electrical conductivity and lightweight properties. It can efficiently conduct high electrical currents and has low resistance, making it ideal for conducting electricity in power distribution systems. Additionally, aluminum sheets can be easily fabricated and formed into various shapes and sizes, allowing for customization and efficient installation in electrical systems.

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Indeed, the utilization of aluminum sheets is possible in the production of heat exchanger fins. Owing to its remarkable thermal conductivity and resistance to corrosion, aluminum stands as a frequently employed substance in heat exchangers. The lightweight and easily malleable attributes of aluminum sheets render them exceptionally suitable for the creation of fins that possess an extensive surface area, thereby augmenting heat transfer. Furthermore, aluminum is readily accessible and cost-efficient, solidifying its status as a favored selection within the realm of heat exchanger manufacturing.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: Status of aluminum sheet F

- H is the hardening state, should be followed by a digital representation of what the work hardening and degree of hardness, suitable to improve the strength of the product through the hardening product in hardening after after (or not after) additional heat treatment makes the strength decreased.The status of aluminum sheet is basically divided into five kinds, in addition to the above three kinds, there are two kinds of W and T:W solid fusion heat treatment state, an unstable state, is only applicable to naturally aged alloy at room temperature after solid solution heat treatment.

- Q: Are there any formulators out there that have any ideas on putting together a cleaner that removes carbon (baked on grease) from an aluminum pan without attacking the meatal itself?? Ive been thinking about this problem for a while and would appriciate any ideas you guys might have. Thanks

- try GOJO hand cleaner with a Sung. you dont need to scrub hard and it will remove the baked on grease.

- Q: Heating aluminum plate, heating scheme, urgent ~!

- For aluminum heating silicon heating plate is a good choice. The four corners can be fixed by screws, Beijiao can. Installation is very convenient. I was in the goodway procurement. They are guaranteed for one year.

Send your message to us

Selling 0.3-10mm 1100,5052,5083,6082,8011,3003,7075 aluminum sheets factory direct sales

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords