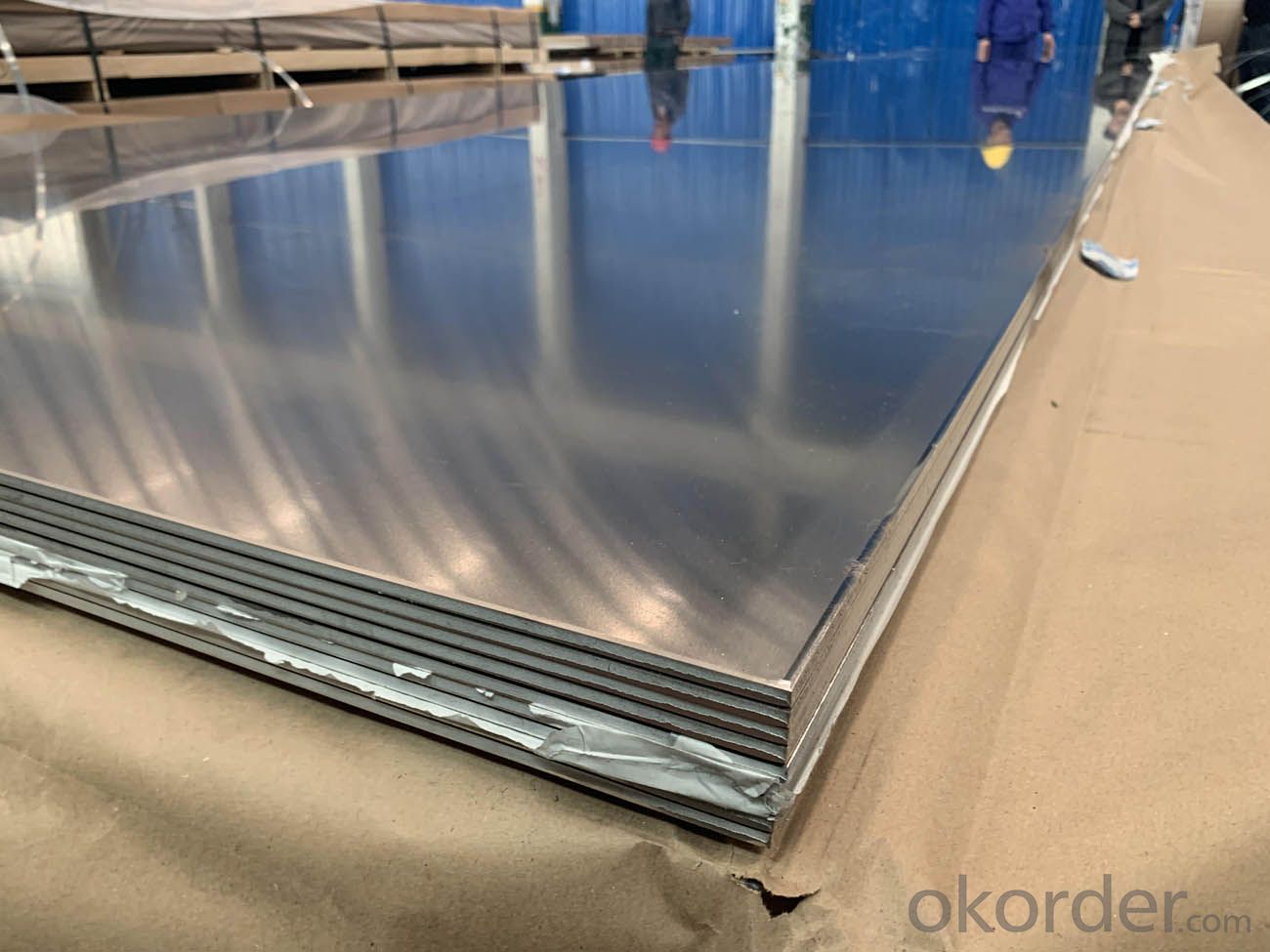

High quality 5083 H116/H321/H112 aluminum plates for ships, DNV/CCS certified sheets

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

5083 aluminum alloy belongs to the Al-Mg series of rust-proof aluminum alloys, which has strong resistance to seawater corrosion and good weldability and machinability. Among them, 5083 aluminum plates in H116, H321 and H112 states are widely used in the shipbuilding industry due to their different processing technology and performance characteristics.

H116 state: After special heat treatment and anti-corrosion treatment, it is suitable for structural parts in seawater environment for a long time, such as hull and deck.

H321 state: Through stabilization treatment, it can maintain excellent stress corrosion resistance after welding, and is often used in marine engineering and high-end shipbuilding.

H112 state: suitable for processing scenarios that require high plasticity, such as ship frame structures and internal support components.

Advantages of marine 5083 aluminum plate:

1. Moderate strength: Good strength performance in non-heat-treatable alloys.

2. Good corrosion resistance: It is a typical rust-proof aluminum plate that can adapt to harsh marine environments.

3. Good weldability: Good welding crack resistance, and cracks are not easy to appear during welding.

4. Good cold working performance: Easy to perform various cold working operations.

5. Low density: It can reduce the weight of the ship plate, save energy consumption, and increase the load.

Parameters:

| Alloy | 5083 |

| Temper | O-H112 |

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 1000-16000mm |

| Packing | Seaworthy wooden pallet. |

| MOQ | 1 tons |

Application of 5083 marine grade aluminum plate in ships:

1. Shipbuilding deck: used to construct the deck part of the ship, providing sufficient strength and corrosion resistance.

2. Engine pedestal: key parts to support and fix the engine, requiring the material to have high strength and good weldability.

3. Side and bottom outer plates: these parts are in contact with seawater for a long time, requiring the material to have excellent corrosion resistance.

DNV/CCS certified plates

DNV certification: DNV (Det Norske Veritas) is an internationally renowned classification society, and its certification indicates that the plates meet international maritime standards and specifications.

CCS certification: CCS (China Classification Society) is the China Classification Society, and its certification indicates that the plates meet the relevant requirements and standards of the China Maritime Safety Administration.

5083 H116/H321/H112 aluminum plates are DNV/CCS certified, which means that these plates have passed rigorous testing and audits, meet international and domestic maritime standards, and are suitable for shipbuilding.

Packaging and transportation

(1) Standard seaworthy export packaging, wooden pallet, plastic protection;

(2) 16-20MT can be loaded into a 20-foot container

(3) The packaging is very strong, with 3 layers, thick fiberboard, foam, plastic, and enough desiccant.

Company information:

Our company is a professional aluminum processing manufacturer located in Zhengzhou, Henan, mainly producing 1 series, 3 series, 5 series, 6 series, 8 series pure aluminum and aluminum alloy sheet, strip and foil products.

We specialize in the production of aluminum plates, aluminum alloy plates, aluminum foils, aluminum strips, aluminum discs, etc. The alloys include 1050, 1100, 3003, 3104, 5052, 5086, 5754, 6061, 6063, 6082, 7075, 8011, 8021, etc., which are used to produce marine aluminum plates, aluminum profiles, aluminum discs for cookware, PTP aluminum foil, aluminum foil for lunch boxes, aluminum sealing plates for Ropp lids, medical PVC films, aluminum-plastic packaging, etc. The products are at preferential prices, sold directly by the manufacturer, exported overseas, and free samples are provided.

Faq:

Q1: How to ensure the quality?

A1: Factory test certification is provided with shipment, third-party inspection is available

Q2. What are the main products of your company?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, PVC hard sheet, pvc/pvdc composite hard sheet, aluminum-plastic blister packaging, etc.

Q3: Where is your factory located?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal material for building boats and ships. It also offers good thermal conductivity and is easily weldable, making it a popular choice in the marine industry.

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: How do aluminum sheets perform in terms of wear resistance?

- Aluminum sheets have good wear resistance due to their natural ability to form a protective oxide layer on their surface. This oxide layer helps to prevent corrosion and wear, making aluminum sheets suitable for various applications requiring durability and resistance to wear.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: avaliable in the uk preferably in a high street store and preferably anti-perperant aswell

- Are you allergic to aluminum or are you refusing to use it because it is not natural? Aluminum has solid research to back its antiperspirant ability. As long as the deodorant or antiperspirant is well-formulated, it is good. There is no best. You should make a search on Amazon UK with key word like natural or organic deodorant or antiperspirant because those terms usually filter out aluminum ones. But, whether or not it will be effective is a different story.

- Q: What is the typical density of aluminum sheets?

- The typical density of aluminum sheets is approximately 2.7 grams per cubic centimeter (g/cm³). Aluminum is a lightweight metal with a relatively low density compared to other commonly used metals such as steel. This low density makes aluminum sheets suitable for various applications where a lightweight material is desired, such as in the aerospace industry, automotive manufacturing, and construction.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are various types of alloys used for powder-coated aluminum sheets, including 3003, 5052, and 6061.

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets may differ based on different factors like sheet thickness, aluminum alloy composition, and manufacturing process employed. Typically, the shear strength of 101 aluminum sheets falls between 20,000 and 30,000 pounds per square inch (psi). Nevertheless, it should be emphasized that these values are approximate, and precise figures can vary. For precise information on the shear strength of 101 aluminum sheets, it is advisable to refer to the material's technical data sheet or contact the manufacturer directly.

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a versatile and durable material that is commonly used for various applications, including backsplashes in kitchens. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum sheets can be easily cut and installed, making them a popular choice for modern kitchen designs. Additionally, they are available in a wide range of finishes and colors, allowing homeowners to find a style that complements their kitchen décor. Overall, aluminum sheets are an excellent option for kitchen backsplashes due to their practicality, aesthetic appeal, and ability to withstand the demands of a busy kitchen environment.

Send your message to us

High quality 5083 H116/H321/H112 aluminum plates for ships, DNV/CCS certified sheets

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords