4x8 Sheets of Aluminum Diamond Plate - Continuous Casting Aluminium Coils for Kitchen Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

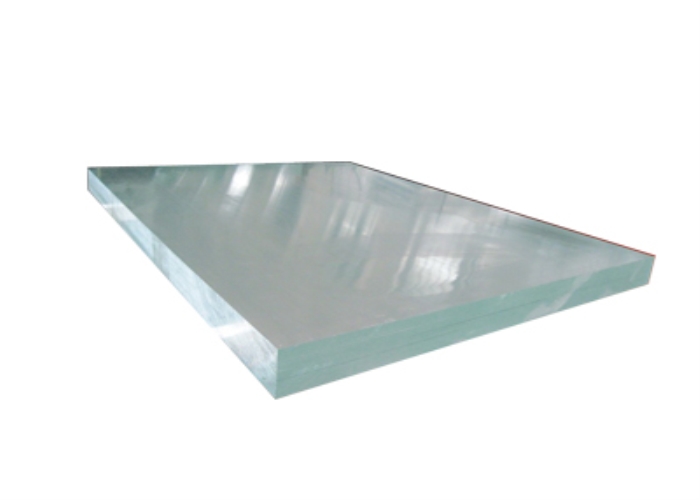

1.Structure of Continuous Casting Aluminium Coils for Kitchen Cup

Continuous Casting Aluminium Coils for Kitchen Cup is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coils for Kitchen Cup

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA1050 | H18 | 0.2MM-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: What is aluminium plate L2-Y2?

- L2Y2 is an industrial pure aluminum sheet:1, L2: China's industrial pure aluminum grades are limited by impurities to prepare, such as L1, L2, L3...... L, is the "aluminum" word Pinyin prefix, followed by the attached order number is bigger, its purity is low. Industrial pure aluminum is generally defined as aluminum with a purity of 99% to 99.9%, and China is designated as 98.8% - 99.7% aluminum.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Unless the surface was specially prepared the aluminum won't bond to the steel. To be sure it doesn't, simply 'smoke ' the steel with a candle etc. (thin layer of carbon black), to ensure no bonding. Your problem will come from the different co-efficients of expansion. The aluminum will shrink more than the steel in cooling and will grab that rod very tightly. Your hole, ( therefore your rod), will have to have a considerable taper if you ever hope to drive that rod out of the casting. Caution- You are aware that most aluminum alloys will burn in air at pouring temperatures aren't you?

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Metal plate curtain wall deformation resistance is poor, the plate strength and steel are not high enough, waterproof sealing performance is not good enough, easy to fade, deformation, also can cause light pollution. Construction and installation technical requirements are relatively high.Stone curtain wall is now used most, but more stereotyped, and negative news constantly, stone fell, heavy stones, high-rise building exterior wall of high risk, poor fire performance.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Good chemical resistance properties are typically found in aluminum sheets. However, their performance may vary depending on the specific chemical environment and conditions. Aluminum is known for its excellent resistance to corrosion from most acids, alkalis, and organic solvents. It creates a protective oxide layer on its surface, preventing further reaction with numerous chemicals. Nevertheless, aluminum can corrode in certain aggressive environments, such as strong acids like hydrochloric acid or sulfuric acid, as well as alkaline solutions with high pH levels. In these instances, the protective oxide layer can deteriorate, leading to the degradation of the aluminum surface. Furthermore, localized corrosion or pitting can occur on aluminum surfaces when exposed to certain chemicals like mercury and specific salts. Therefore, it is important to consider the specific chemicals and concentrations to which the aluminum sheets will be exposed when evaluating their chemical resistance. Various surface treatments, coatings, or alloys can be applied to enhance the chemical resistance of aluminum sheets. These modifications offer additional protection against specific chemicals or environmental conditions, further improving the overall chemical resistance properties of aluminum sheets. In conclusion, aluminum sheets generally possess good chemical resistance. However, their performance can be influenced by the specific chemical environment and conditions. It is advisable to assess the compatibility of aluminum with the intended chemicals and consider appropriate surface treatments or coatings if necessary.

- Q: Can aluminum sheets be used for decorative purposes?

- Yes, aluminum sheets can definitely be used for decorative purposes. Aluminum is a versatile and lightweight material that can be easily manipulated into different shapes, sizes, and designs. It can be painted, coated, or anodized in various colors to match any aesthetic preference. Aluminum sheets can be used as decorative panels, signage, wall cladding, ceiling tiles, and even in furniture design. Additionally, aluminum is resistant to corrosion, making it a durable option for both indoor and outdoor applications. Its reflective surface can also create a sleek and modern look in any space. Overall, aluminum sheets offer a wide range of possibilities for adding a decorative touch to any project.

- Q: This question asks for a comparison between aluminum sheets and other lightweight materials like plastic and glass, focusing on their properties and uses.

- <p>Aluminum sheets are lightweight yet strong, offering excellent strength-to-weight ratios. They are more durable and heat resistant compared to plastics, which can deform under heat and are less sturdy. Unlike glass, aluminum is less brittle and does not shatter, making it safer for certain applications. Additionally, aluminum is recyclable and has good thermal and electrical conductivity, which is not the case with plastics. However, plastics are generally cheaper and easier to shape into complex forms, while glass offers better transparency for applications requiring clear visibility. Each material has its advantages depending on the specific requirements of the application.</p>

- Q: Can aluminum sheets be used for solar panel applications?

- Yes, aluminum sheets can be used for solar panel applications. Aluminum is a popular choice for solar panel frames and mounting systems due to its lightweight, strength, and corrosion resistance properties. It is also easily recyclable, making it an environmentally friendly option. Aluminum sheets provide structural support and stability to solar panels, ensuring they can withstand various weather conditions and last for a long time. Additionally, aluminum's high thermal conductivity helps dissipate heat generated by the solar panels, improving their overall performance and efficiency.

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

- Q: Are aluminum sheets suitable for automotive suspension components?

- Automotive suspension components can indeed be made from aluminum sheets, which offer numerous advantages. Firstly, aluminum sheets are much lighter than traditional steel components. This reduction in weight can lead to improved fuel efficiency and overall vehicle performance. By reducing the weight of suspension components, the vehicle's handling, acceleration, and braking can be enhanced, resulting in a smoother and more responsive ride. Secondly, aluminum possesses an excellent strength-to-weight ratio. This means that it can provide the necessary structural integrity and support for suspension components while still being lightweight. It has high tensile strength and stiffness, enabling it to withstand the stresses and forces exerted on suspension components during normal driving conditions. Furthermore, aluminum is highly resistant to corrosion, which is especially beneficial for automotive suspension components that are exposed to various environmental conditions. This corrosion resistance ensures the longevity and durability of the suspension system, reducing the need for frequent repairs or replacements. Moreover, aluminum is easily machinable, allowing for the creation of complex and intricate designs that can optimize suspension performance. Its flexibility in shaping and forming enables manufacturers to create suspension components with specific geometries and characteristics to meet the desired performance requirements. In conclusion, aluminum sheets are an excellent choice for automotive suspension components due to their lightweight nature, high strength-to-weight ratio, corrosion resistance, and machinability. These properties make aluminum a preferred material for suspension components, resulting in improved vehicle performance, fuel efficiency, and overall durability.

Send your message to us

4x8 Sheets of Aluminum Diamond Plate - Continuous Casting Aluminium Coils for Kitchen Cup

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords