Column Clamps Formwork

Column Clamps Formwork Related Searches

Fabric Formwork Conventional Formwork System Gliding Formwork Rubber Clamps Moving Formwork System Formwork Gass Formwork Formwork System Formwork Props Formwork Wall Materials For Formwork Rough Formwork Tunnel Formwork System Metal Formwork System Formwork For Concrete Stairs Concrete Formwork System Fabric Formwork For Concrete Steel Formwork System Concrete Boxing Formwork Permanent Formwork System Striking Formwork Strongback Formwork Form Construction Types Of Formwork In Construction Formwork Installation Rammed Earth Formwork Concrete Pit Formwork Fabric Concrete Forms Advanced Concrete Formwork Column SplicesColumn Clamps Formwork Supplier & Manufacturer from China

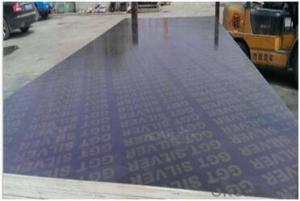

Column Clamps Formwork is a specialized construction product designed to provide support and stability to vertical structures during the pouring and curing of concrete. This innovative system is engineered to ensure precise alignment and secure positioning of formwork, facilitating the creation of sturdy and well-defined columns in various construction projects.The application of Column Clamps Formwork is extensive, encompassing a wide range of usage scenarios in the construction industry. It is commonly used in the erection of high-rise buildings, bridges, and other infrastructure projects where vertical columns are a critical component. This product is particularly advantageous due to its ability to withstand high loads and maintain structural integrity, ensuring the safety and durability of the finished construction.

As a leading wholesale supplier, Okorder.com boasts a vast inventory of Column Clamps Formwork, catering to the diverse needs of construction companies worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each order is delivered promptly and in excellent condition, providing contractors with the tools they need to execute their projects efficiently and effectively.

Hot Products