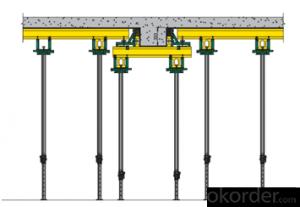

Scaffolding Formwork Beam Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Model Number: | ||||

| Usage: | Structure: |

Packaging & Delivery

| Packaging Detail: | small box or bulk packaging, according to your requests |

| Delivery Detail: | 45 Days after receiving TT deposit payment |

Specifications

1.Country of Origin 2.Experienced Staff 3. High-quality products4.Guarantee/Warranty 5.Packaging 6.Price 7.Product Features

Beam Clamp

Cast Malleable Steel/Carbon Steel/Ductile Iron

hardened steel screw, zinc-plated,

Rod Size: M8~M12

Beam Clamp

1. Material: Steel with hardened cup point set screw and jam nut;

2. Finish: Electro-galvanized finish for enhanced corrosion protection,

Available in hot dip galvanized fi nish (special order);

3. Features: May be used on top or bottom flange of the beam. Beveled lip allows hanging from top flange where clearance is limited. may be installed with the set screw in the up or down position. Offset design permits unlimited rod adjustment by allowing the rod to be threaded completely through the clamp. The rear window design permits inspection of thread engagement;

4. Function: For attachment to structural shapes requiring wider throat especially under roof with bar joist construction. This clamp may be used with the set screw in the up or down position;

5. Note: Do not over tighten set screw.

- Q: What are the components of a mobile scaffolding

- The utility model relates to a standard steel pipe scaffold which is connected with the main structure of the wall and is connected with the main structure of the building.

- Q: The role of the external scaffolding and the relevant provisions?

- Scaffolding outside the building in the construction of the building is an indispensable important tool for erection. Its role: first, can make the construction personnel in different parts of the operation of the high; two is to ensure the safety of construction personnel in the high altitude operation

- Q: hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- carefully clean the fresh blood off then leave it alone after that - dont keep removing the dry blood - then clean it with saline solution/salt water and antibacterial stuff

- Q: Where to use scaffolding in construction

- 5, the level should be closed: the first step, every step or two, covered with planks or hand foot fence, scaffolding to laying along the long, joints should be overlapped in the small bar, do not appear short board. And in between in the pole and the wall every four steps long laying safety bottom fence.6, vertical closure: from the second step to the fifth step, each step required in the outer row of pole side door set like baluster 1.00m high and block feet or to set up protective net, rod (net) and the vertical rod fastened; more than fifth steps in a protective railing, should all the safety fence or security legislation net; in the street or densely populated areas, should be from the second step, the safety fence or outside of all network security legislation.

- Q: Fastener type steel pipe scaffold accessories

- fastenerFastener type steel pipe scaffold fastener malleable iron casting should be adopted, its basic form has three kinds: vertical cross bar for a connection between the rectangular fastener, fastener for rotating connecting parallel or oblique bars and rods for butt joint butt joint fastener.

- Q: What is rolling scaffolding?

- well rolling scaffoled is just what it says,its rolling scaffold.Some scaffold is set up in a way it is not movable,its ushally attached to a structure ,for safty.a rolling scaffold although its not as stable as attached ,its movable,it can be rolled along the area needed to be worked,often with men staying on it while its rolled.

- Q: Bowl buckle type steel pipe scaffolding should set up a few people

- What are the form and structure of bowl buckle scaffold?Composition formA bowl type steel tube scaffold is a multifunctional scaffold in our country with reference to foreign experience developed, its member nodes connected with bowl, because the bowl is fixed on the steel pipe, all components of the axial connection, good mechanical properties, which is reliable, consisting of the scaffold with good integrity, there is no fastener lost problem.

- Q: Standard Specification for bowl buckle scaffold

- A new type of scaffold developed in China

- Q: Im a wimp for pain and im looking to get my scaffolding done. i want to know how painful it isI already have both lobs pierced and stretched to an 8mm, will the pain be similar to that?

- Depends on your pain tolerance, it's different for everyone. But generally cartilage piercings feel nothing like getting piercings stretched.

- Q: male scaffolders only if i was swinging on the scaffold would ya stomp on my fingers with ya workboots on?

- Had a hooker climb up the ladder to the 3ed floor one time....didn't stay long though!

Send your message to us

Scaffolding Formwork Beam Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords