column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

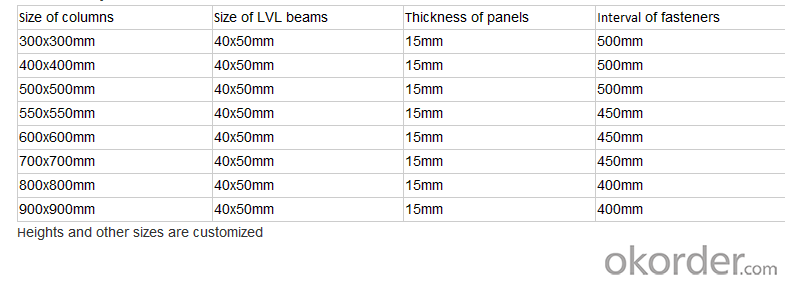

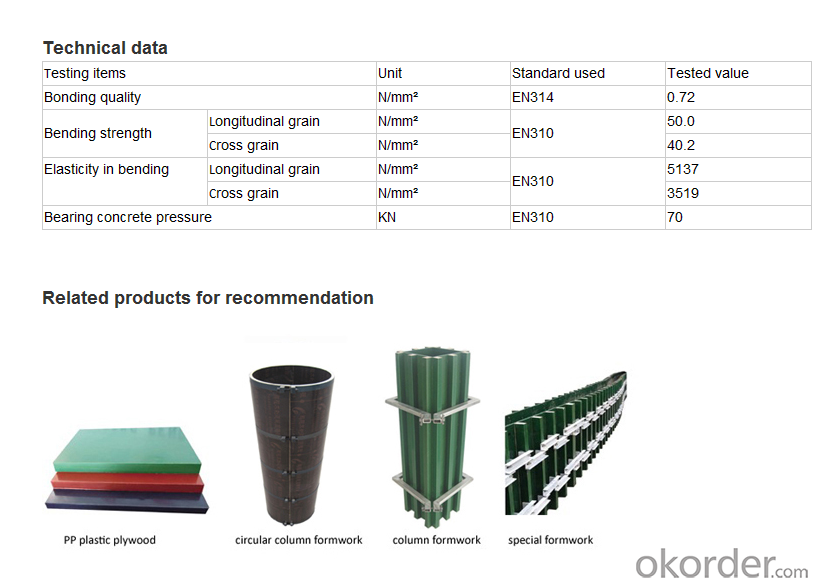

Specification

china quick form concrete column formwork

Application

column formwork for concrete forming of square columns

Installation

as easy as film faced plywood, but no need release agent

Dismantling

Handle carefully without violent damage and scratch to ensure more usage in good condition

Cleaning

Just clean by water

Maintenance & Storage

No oil treatment, place the panel flat, away from direct sunlight and water.

Product options

Advantages

1. reusable 50 times at least

2. quick installation & seamless joining to prevent the leakage of concrete

3. painted accessories, high resistance to rust

4. quick dismantling without concrete release agent

5. nice concrete finish without reworkP

Packing

- Q: Are there any specific guidelines for pouring concrete into steel frame formwork?

- Yes, there are specific guidelines for pouring concrete into steel frame formwork. These include ensuring that the formwork is properly aligned and securely braced, using the correct concrete mix design and slump, and ensuring that the concrete is evenly spread and compacted within the formwork. Additionally, it is important to monitor the pour for any potential issues such as segregation or excessive vibration, and to follow proper curing and finishing procedures.

- Q: What are the considerations for selecting the appropriate formwork for different concrete curing durations?

- When selecting the appropriate formwork for different concrete curing durations, there are several considerations that need to be taken into account. These considerations include: 1. Type of formwork: The type of formwork chosen will depend on the specific requirements of the project. Different types of formwork, such as traditional timber formwork, engineered formwork systems, or reusable plastic formwork, may have different capabilities and limitations in terms of supporting concrete during curing. 2. Durability and strength: The formwork needs to be strong enough to support the weight of the concrete during curing. The material used for formwork should have sufficient strength and durability to withstand the pressure exerted by the fresh concrete. This is particularly important for longer curing durations as the concrete will be more susceptible to shrinkage and cracking. 3. Reusability: If the project requires multiple concrete pours or if the formwork needs to be reused for other projects, selecting formwork that is reusable will be more cost-effective and efficient. Reusable formwork systems, such as engineered systems or plastic formwork, can be assembled and disassembled easily, allowing for multiple uses. 4. Time constraints: The time available for formwork installation and removal is an important consideration. If there are strict project deadlines or if the formwork needs to be removed quickly to allow for subsequent construction activities, selecting formwork that allows for easy and fast installation and removal will be essential. 5. Cost: The cost of formwork plays a significant role in the selection process. Different formwork systems have varying costs, and it is important to consider the overall project budget and the cost-effectiveness of the formwork solution chosen. Additionally, the potential for reusing formwork can help reduce costs in the long run. 6. Environmental factors: Environmental conditions, such as temperature and humidity, can affect the curing duration of concrete. It is essential to select formwork that can withstand these conditions without compromising the integrity of the concrete. For example, in hot and dry climates, formwork that provides adequate moisture retention can help prevent excessive evaporation and ensure proper curing. 7. Safety: Formwork needs to be designed and installed in a way that ensures the safety of workers and the structural stability of the formwork system. Considerations such as load capacity, stability, and proper bracing should be taken into account to minimize the risk of accidents during the concrete curing process. Overall, selecting the appropriate formwork for different concrete curing durations requires careful evaluation of factors such as type, strength, reusability, time constraints, cost, environmental conditions, and safety. By considering these factors, the right formwork can be chosen to support the concrete curing process effectively and efficiently.

- Q: How does steel frame formwork compare to other formwork systems in terms of durability?

- Compared to other formwork systems, steel frame formwork is renowned for its exceptional durability. This can be attributed to the inherent strength and resilience of steel as a construction material. Steel possesses a high tensile strength, enabling it to withstand heavy loads and resist deformation or structural failure. Unlike timber or aluminum formwork systems, steel frame formwork is less prone to warping, rotting, or corrosion. As a result, it exhibits high resistance to the elements, allowing it to endure extreme weather conditions and maintain its structural integrity for an extended period. Moreover, the design of steel frame formwork emphasizes reusability, which further enhances its overall durability. The system's modular nature facilitates easy assembly and disassembly, minimizing damage during the construction process. Once a project is completed, the formwork can be dismantled and utilized in future projects, reducing waste and generating cost savings. When it comes to durability, steel frame formwork offers a significant advantage over alternative systems. Its robustness, resistance to deterioration, and ability to be reused make it a reliable choice for construction projects, especially those that require long-lasting structures.

- Q: How to get PKPM steel frame

- Is there a video tutorial? The 2010 edition of PKPM

- Q: How does steel frame formwork accommodate for different concrete pumping methods?

- Steel frame formwork can accommodate different concrete pumping methods by providing a sturdy and flexible structure that can be easily adjusted and adapted to suit the specific requirements of each pumping method. The steel frames can be designed to withstand the pressure and force exerted by the concrete during pumping, ensuring safety and stability. Additionally, the formwork can be easily modified or reinforced as needed to accommodate different pumping techniques, such as boom or line pumps, allowing for efficient and precise concrete placement.

- Q: What are the different finishes available for steel frame formwork?

- Depending on the construction project's specific requirements, there are various finishes available for steel frame formwork. One possibility is a galvanized coating, which involves applying a layer of zinc to the steel surface. This coating is highly resistant to corrosion, making it suitable for projects in harsh environments or those exposed to moisture and chemicals. Additionally, galvanized finishes provide a smooth and uniform appearance, enhancing the formwork's aesthetic appeal. Another option is a powder-coated finish, where a dry powder is electrostatically applied to the steel surface and then cured under heat. This coating offers durability, abrasion resistance, and a wide range of color options. Powder-coated finishes are ideal for projects that require a specific aesthetic or branding. In situations where the steel formwork needs to withstand extreme temperatures or high levels of wear and tear, a fire-resistant or heat-resistant finish may be applied. These finishes are designed to protect against fire, heat, and thermal shock, ensuring the formwork's longevity and safety. Additionally, painted finishes can be used to provide a decorative or protective coating on the steel frame formwork. These finishes can be customized to match the project's color scheme or offer additional corrosion protection. Ultimately, the choice of finish for steel frame formwork will depend on the project's specific needs, including environmental conditions, desired aesthetics, and required performance characteristics. Consulting with a professional is crucial to determine the most suitable finish for a particular construction application.

- Q: Can steel frame formwork be used in projects with restricted material availability?

- Projects with limited material availability may find steel frame formwork to be a viable option. When steel frame formwork is utilized, numerous advantages are presented in such scenarios. To begin, steel is a strong and enduring material that can withstand harsh conditions and heavy loads, making it suitable for a wide range of construction projects. Furthermore, steel formwork can be reused multiple times, reducing the need to frequently replace materials. This attribute is particularly advantageous in projects that have limited access to construction materials. Additionally, steel frame formwork can be easily transported and assembled, enabling efficient construction even in areas where materials are scarce. In conclusion, the utilization of steel frame formwork can be a practical resolution for projects that have limited material resources, guaranteeing cost-effectiveness and timely completion.

- Q: What are the different types of connections used in steel frame formwork?

- There are several different types of connections used in steel frame formwork, each serving a specific purpose and providing different advantages. 1. Wedge connections: This type of connection involves the use of steel wedges to secure the formwork panels together. Wedges are inserted into pre-drilled holes in the panels, and as they are hammered in, they create a tight and secure connection. Wedge connections are quick and easy to assemble and disassemble, making them ideal for projects with repetitive formwork requirements. 2. Clamp connections: Clamp connections involve the use of steel clamps to hold the formwork panels together. These clamps are designed to grip the edges of the panels and provide a strong and stable connection. Clamp connections offer excellent strength and stability, making them suitable for complex and heavy-duty formwork applications. 3. Pin connections: Pin connections utilize steel pins to connect the formwork panels together. These pins are inserted into pre-drilled holes and secured with nuts or other fasteners. Pin connections provide good strength and stability and are commonly used in formwork systems that require frequent adjustments or reconfigurations. 4. Bolted connections: Bolted connections involve the use of steel bolts and nuts to join the formwork panels together. The panels are drilled with holes, and the bolts are inserted through these holes and tightened with nuts. Bolted connections provide high strength and rigidity, making them suitable for large-scale formwork systems and projects with heavy loads. 5. Magnetic connections: Magnetic connections are a relatively new type of connection used in steel frame formwork. They utilize powerful magnets embedded in the formwork panels to attract and hold the panels together. Magnetic connections offer quick and easy assembly and disassembly, as well as high flexibility and adaptability in formwork design. Each type of connection has its own advantages and suitability for specific formwork applications. The choice of connection depends on factors such as project requirements, formwork design, load capacity, ease of assembly, and time constraints.

- Q: How does steel frame formwork address issues of concrete shrinkage and expansion?

- Steel frame formwork is a construction technique that effectively addresses the issues of concrete shrinkage and expansion. Firstly, steel is known for its high tensile strength, which means it can withstand the forces exerted by concrete during the shrinkage and expansion process. This prevents any cracking or damage to the concrete structure. Additionally, steel frame formwork provides a rigid and stable framework for pouring concrete. This ensures that the concrete is evenly distributed and properly supported, minimizing the risk of uneven shrinkage or expansion. The steel frame also acts as a barrier, preventing the concrete from expanding beyond its intended dimensions. Moreover, steel frame formwork allows for the use of expansion joints. These joints are strategically placed in the formwork to accommodate the natural movements of the concrete caused by temperature changes and moisture variations. By incorporating these expansion joints, the steel frame formwork allows the concrete to shrink and expand without causing any structural issues or damage. Furthermore, steel frame formwork can be easily adjusted and modified to accommodate changes in concrete dimensions due to shrinkage or expansion. This flexibility allows for the necessary adjustments to be made during the construction process, ensuring a precise and accurate final product. In conclusion, steel frame formwork addresses the issues of concrete shrinkage and expansion by providing a strong and stable framework, incorporating expansion joints, and allowing for easy adjustments. This construction technique ensures that the concrete structure remains intact and free from any damage caused by these natural processes.

- Q: Can steel frame formwork be used in projects with high architectural finish requirements?

- Projects with high architectural finish requirements can indeed make use of steel frame formwork. The utilization of steel frame formwork guarantees a remarkable level of accuracy and stability, thereby ensuring a uniform and precise architectural finish. This is of utmost importance in achieving a smooth and flawless end result. The steel frames can be easily adjusted and tailored to fit various shapes, curves, and angles, thereby accommodating intricate and complex architectural designs. Furthermore, steel frame formwork exhibits exceptional durability and is able to withstand the immense pressure exerted by the concrete during the pouring process. This ensures that the formwork remains intact and maintains its shape throughout the construction process. In conclusion, steel frame formwork is a dependable and adaptable choice that can fulfill the high architectural finish requirements of diverse construction projects.

Send your message to us

column formwork accessories adjustable clamp

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords