Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork-Light duty frame formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light duty steel frame formwork

-Simply assemble and disassemble.

-Film faced plywood used to repeat its use with almost 40 times

-Smooth concrete surface to reduce post processing fees.

-Accessories used effectively(such as nail, steel wire, tie rod..).

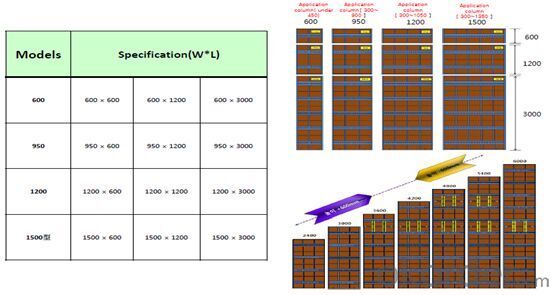

-Adjustable sizes (1200 steel frame formwork can be adjusted from minimum300mm to maximum 1050mm)

-Easy to move and remove

-Parts used in column steel frame formwork can be used in wall steel frame formwork

3. Light Duty Steel Frame Formwork Images

4. Light Duty Steel Frame Formwork Specifications

Column steel frame formwork sizes

5. FAQ of Light Duty Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Duty Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of formwork shoes used in steel frame formwork systems?

- The different types of formwork shoes used in steel frame formwork systems include adjustable shoes, base plates, jack bases, and leveling screws. Adjustable shoes are used to provide height adjustment and leveling capabilities, while base plates are used to distribute the load of the formwork system. Jack bases are used to support the vertical loads, and leveling screws are used to fine-tune the leveling of the formwork system.

- Q: Can steel frame formwork be used for both regular and irregular-shaped concrete structures?

- Yes, steel frame formwork can be used for both regular and irregular-shaped concrete structures. The versatility and flexibility of steel frame formwork allow it to adapt to different shapes and sizes, making it suitable for various construction projects.

- Q: Can steel frame formwork be used for precast concrete elements?

- Yes, steel frame formwork can be used for precast concrete elements. Steel frame formwork offers high strength, durability, and versatility, making it suitable for creating different shapes and sizes of precast concrete elements. Additionally, steel frame formwork provides excellent support and stability during the casting process, ensuring the accurate formation of precast concrete elements.

- Q: How does steel frame formwork handle the placement of concrete in congested areas or tight spaces?

- Steel frame formwork is specifically designed to handle the placement of concrete in congested areas or tight spaces effectively. Its flexible and modular nature allows for easy customization and adaptation to fit any challenging construction site. Additionally, the steel frame formwork provides a sturdy and stable structure that can withstand the pressure exerted by the concrete, ensuring the integrity of the formwork system during the pouring process. The compact design of steel frame formwork also allows for efficient utilization of space, making it an ideal choice for congested areas or tight spaces where traditional formwork systems may not be feasible.

- Q: How does steel frame formwork contribute to the overall cost of a construction project?

- Steel frame formwork can contribute to the overall cost of a construction project in several ways. Firstly, it may require a higher initial investment compared to other types of formwork, such as timber or aluminum. However, this cost is often justified by its durability and reusability, as steel formwork can withstand multiple uses without significant wear and tear. Additionally, steel formwork can help to expedite the construction process by allowing for faster assembly and disassembly, reducing labor costs. Moreover, its strength and stability can minimize the need for additional support structures, saving on material costs. Overall, while steel frame formwork may have a higher upfront cost, its efficiency and longevity can result in long-term cost savings for the construction project.

- Q: How does steel frame formwork help in achieving accurate concrete curing?

- Steel frame formwork is utilized in the construction industry to shape and support concrete structures during the process of curing. It comprises a steel frame, typically constructed from high-quality steel, with adjustable panels that can be tailored to fit the desired dimensions and shape of the concrete structure. One of the notable advantages of steel frame formwork lies in its capacity to achieve precise concrete curing. This is accomplished through several contributing factors: 1. Stability and precision: Steel frame formwork is engineered to be rigid and steadfast, ensuring that the concrete is poured and maintained in the desired shape and position. This helps prevent any distortion or displacement of the concrete during the curing process, leading to accurate and consistent curing. 2. Customizability: The adjustable panels of steel frame formwork permit meticulous customization of the formwork to align with the specific dimensions and contours of the concrete structure. This guarantees that the concrete is poured and cured in the exact shape and dimensions required, resulting in precise and uniform curing. 3. Longevity: Steel frame formwork is composed of high-quality steel, rendering it highly durable and long-lasting. This durability ensures that the formwork remains intact and stable during the curing process, preventing any shifting or movement that could compromise the accuracy of the concrete curing. 4. Easy removal: Steel frame formwork is designed for effortless removal once the concrete has fully cured. This ease of removal minimizes any disturbance to the cured concrete, enabling it to retain its precise shape and curing characteristics. All in all, steel frame formwork plays a critical role in achieving accurate concrete curing by providing stability, precision, customizability, longevity, and easy removal. These factors collaborate to ensure that the concrete is poured and cured in the desired shape, dimensions, and quality, resulting in a robust and enduring concrete structure.

- Q: What are the different types of formwork corner solutions available for steel frame formwork systems?

- There are several different types of formwork corner solutions available for steel frame formwork systems. These solutions are designed to provide efficient and effective support for the corners of concrete structures during the construction process. One common type of formwork corner solution is the adjustable corner bracket. This bracket is typically made of steel and is designed to be easily adjustable to accommodate different angles and dimensions of corners. It provides a stable and secure support for the formwork panels at the corners, ensuring that the concrete structure is properly formed and aligned. Another type of formwork corner solution is the corner lock. This is a device that is used to connect and secure the formwork panels at the corners. The corner lock is typically made of steel and is designed to provide a strong and reliable connection, ensuring that the formwork panels remain in place during the pouring and curing of the concrete. Additionally, there are corner connectors available for steel frame formwork systems. These connectors are designed to provide a quick and easy way to connect the formwork panels at the corners. They are typically made of steel or other durable materials and are designed to withstand the pressures and forces exerted during the concrete pouring process. Furthermore, some formwork corner solutions include corner braces or supports. These braces are typically made of steel or other strong materials and are designed to provide additional support and stability to the formwork panels at the corners. They help to ensure that the formwork system remains rigid and secure, even under the weight and pressure of the concrete. Overall, the different types of formwork corner solutions available for steel frame formwork systems provide a range of options to ensure that corners are properly supported and aligned during the concrete construction process. These solutions are designed to be durable, adjustable, and easy to use, providing contractors with the tools they need to create strong and reliable concrete structures.

- Q: Can steel frame formwork be used in areas with limited space for storage?

- Indeed, areas with limited storage space can utilize steel frame formwork. Its versatility and compactness are well-known, rendering it appropriate for projects with restricted storage capacity. Unlike conventional formwork systems, steel frame formwork can be effortlessly disassembled and reassembled, enabling efficient utilization of storage space. Furthermore, its lightweight nature and ease of transportation enhance its suitability for areas with limited storage capability. In summary, steel frame formwork proves to be a pragmatic and flexible solution for construction projects in confined spaces.

- Q: How does steel frame formwork contribute to better formwork stability during concrete pouring?

- The utilization of steel frames as the main structural support for pouring concrete is known as steel frame formwork. This construction technique offers numerous advantages in terms of formwork stability during the concrete pouring process. To begin with, steel frame formwork provides a superior level of strength and rigidity. The steel frames are specifically designed to withstand the pressure exerted by the liquid concrete, guaranteeing the stability of the formwork and preventing any deformation or collapse under the weight. This is particularly crucial when dealing with large volumes of concrete or when constructing structures that require high load-bearing capacity. Furthermore, steel frame formwork allows for precise alignment and positioning of the formwork. The frames can be easily adjusted and leveled, ensuring accurate and even pouring of the concrete. This is essential in achieving a smooth and uniform finish and maintaining the structural integrity of the concrete elements. Moreover, steel frame formwork boasts exceptional durability and resistance to wear and tear. Unlike traditional timber formwork, steel frames do not warp, shrink, or deteriorate over time. Consequently, the formwork can be reused multiple times, reducing costs and waste associated with formwork materials. The durability of steel frame formwork also contributes to enhanced stability during concrete pouring, minimizing the risk of unexpected failures or collapses. Additionally, steel frame formwork expedites construction processes and makes them more efficient. The pre-fabricated steel frames are easily transportable and can be swiftly assembled, reducing the time and effort required for formwork installation. Consequently, the concrete pouring process is accelerated, minimizing the likelihood of delays or disruptions. The efficiency of steel frame formwork enhances formwork stability by facilitating a smoother and more controlled pouring process. In summary, steel frame formwork enhances formwork stability during concrete pouring through its high strength and rigidity, precise alignment and positioning capabilities, durability, and efficiency. By utilizing steel frames as the primary support structure, this construction technique secures the stability of the formwork, resulting in a successful and safe concrete pouring process.

- Q: Can steel frame formwork be used in combination with post-tensioning techniques?

- Combining post-tensioning techniques with steel frame formwork is possible. Post-tensioning involves reinforcing concrete structures by inserting steel tendons into the concrete and then applying tension to the tendons once the concrete has cured. This method enhances the strength and durability of the structure. In contrast, steel frame formwork is a system utilized to create temporary molds for pouring concrete into desired shapes. It comprises steel frames, panels, and accessories assembled on-site. When implementing post-tensioning techniques, the steel tendons are typically positioned within the concrete prior to erecting the formwork. The steel frame formwork can be customized and adjusted to accommodate the tendons, ensuring their correct placement in the concrete. Moreover, steel frame formwork offers crucial support and stability during the post-tensioning process. The formwork system can withstand the forces resulting from tendon tension without distorting or collapsing, guaranteeing the concrete retains its desired shape and position. Hence, steel frame formwork is indeed compatible with post-tensioning techniques, offering an efficient and effective solution for constructing reinforced concrete structures.

Send your message to us

Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords