Plastic Concrete Formwork for Column Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

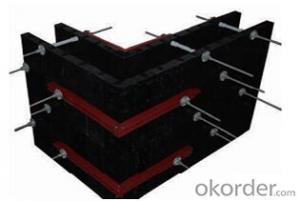

1. Structure of Plastic concrete formwork-Column panel

Plastic concrete formwork is more and more popular in the market. It consist of wall panel, corner panel, column panel, corner block and round panels. It is a very adjustable and flexible modular formwork and works quite efficiently.

The normal size of column formwork is 72*75(H)*7(cm) which weighes 8.8kg.

And it works with only 9 handles and easily set up with other panels.

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 1000px walls.

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment. Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

2. Main Features of Plastic concrete formwork-corner panel

-easy set up

-modularity work

-High strength

-enviroment friendly

-consequent

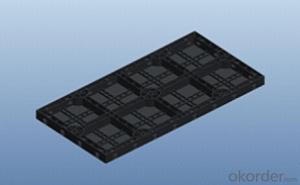

3. Plastic concrete formwork-Corner panel images

4. Plastic concrete formwork-Column panel Specifications

The normal size of column formwork is 72*75(H)*7(cm) which weighes 8.8kg.

And it works with only 9 handles and easily set up with other panels.

5. FAQ of Plastic concrete formwork-Column panel

1) What can we do for you?

.We can ensure the quality of Plastic concrete formwork-column panel and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- Is the template based on your product requirements, can you talk about the requirements of each part of your product?

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template construction is convenient, high efficiency: aluminum alloy building template system assembly is simple, convenient, average weight 30KG / m2, completely assembled by the artificial, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer Easy to install), skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold workers only need to install wood workers 70-80%, and do not need skilled workers, just install Before the construction of the staff can be a simple training can be).

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: Plastic mold dynamic template, the size of the template

- Bigger than the fixed model on the line, a good folder folder.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

Send your message to us

Plastic Concrete Formwork for Column Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords