Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

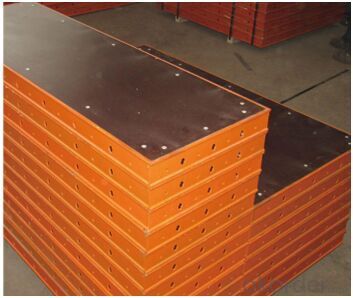

1. Structure of Light Steel Frame Formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light steel frame formwork

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

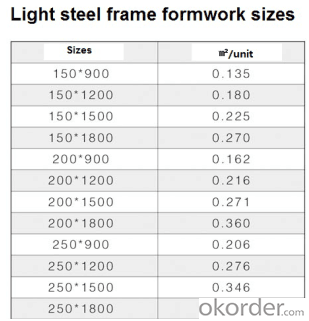

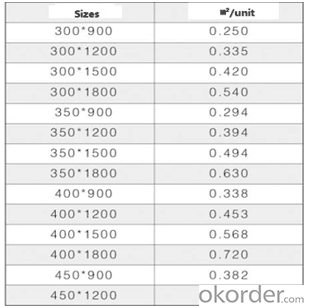

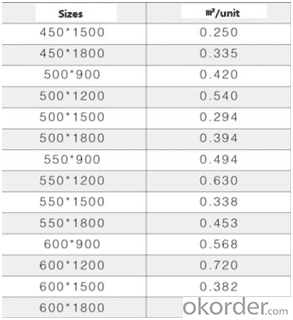

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: How does steel frame formwork handle concrete pouring and vibration?

- Steel frame formwork is specially designed to handle the concrete pouring and vibration process effectively. The steel frame acts as a rigid structure that supports the weight of the fresh concrete and helps to shape it into desired formwork configurations. During concrete pouring, the steel frame formwork is securely fixed in place to ensure stability and prevent any movement or displacement. This is crucial to maintain the integrity and accuracy of the final structure. The steel frame provides a strong and sturdy framework, allowing for the smooth and efficient pouring of concrete. In terms of vibration, steel frame formwork is designed to withstand the forces generated during the concrete vibration process. Vibration is necessary to eliminate any air pockets or voids within the concrete, ensuring a strong and durable final product. The steel frame formwork absorbs and distributes the vibration energy, preventing any deformation or damage to the structure. Moreover, the steel frame formwork is often equipped with additional features to enhance the concrete pouring and vibration process. These may include adjustable leveling devices, tie rods, and clamps that provide additional support and stability. This allows for precise control over the pouring and vibration, resulting in a high-quality finished concrete structure. Overall, steel frame formwork is specifically engineered to handle the demanding conditions of concrete pouring and vibration. Its robust construction and advanced features provide the necessary strength, stability, and control to ensure a successful and efficient concrete construction process.

- Q: How does steel frame formwork contribute to the overall acoustics of a structure?

- Steel frame formwork does not directly contribute to the overall acoustics of a structure. The primary function of steel frame formwork is to provide temporary support and shape for the concrete during the construction process. It is a framework that holds the concrete in place until it hardens and gains its structural strength. However, the overall acoustics of a structure can be influenced by the materials and design choices made during the construction process. Factors such as the selection of building materials, insulation, and the design of walls, floors, and ceilings can have a significant impact on the sound transmission and absorption within a building. To improve the acoustics of a structure, specific acoustic measures need to be implemented, such as the use of sound-absorbing materials, acoustic insulation, and the design of spaces to reduce sound reflections. Steel frame formwork itself is not designed to contribute to these acoustic properties, but it can indirectly affect the acoustics by providing a strong and stable structure that allows for the installation of acoustic materials and soundproofing systems. In summary, while steel frame formwork does not directly contribute to the overall acoustics of a structure, it can play a role in providing a solid foundation for implementing acoustic measures that can enhance sound transmission and absorption within a building.

- Q: What are the common maintenance and repair procedures for steel frame formwork systems?

- Common maintenance and repair procedures for steel frame formwork systems typically involve regular inspections and maintenance tasks to ensure the durability and functionality of the system. Here are some common procedures: 1. Regular Cleaning: It is important to clean the steel frame formwork system after each use to remove any concrete residues, dirt, or debris. This can be done by using water, brushes, or pressure washers. Regular cleaning helps prevent the build-up of corrosive substances and ensures that the formwork remains in good condition. 2. Rust Removal: Steel frames are susceptible to rust, especially if exposed to moisture or corrosive materials. Regularly inspect the formwork for any signs of rust or corrosion. If rust is detected, it should be removed using appropriate rust removal techniques, such as sanding, wire brushing, or chemical rust removers. Once the rust is removed, the affected areas should be treated with anti-rust coatings to prevent future corrosion. 3. Alignment and Straightening: Over time, steel frame formwork systems may become misaligned or bent due to heavy loads or improper handling. Regularly check the alignment of the frames and ensure that they are straight and level. If any misalignment or bending is observed, the frames should be realigned or straightened using appropriate tools and techniques. This is essential to maintain the accuracy and stability of the formwork system. 4. Welding Repairs: If any cracks or damages are found in the steel frames, welding repairs may be necessary. Welding should be done by trained professionals using the appropriate welding techniques and equipment. This helps ensure the structural integrity of the formwork system and prevents further damage. 5. Lubrication: Some steel frame formwork systems have moving parts, such as hinges or adjustable components. Regularly lubricating these parts with suitable lubricants helps prevent friction and ensures smooth operation. Lubrication also helps protect the system from rust and corrosion. 6. Inspection of Accessories: In addition to the steel frames, it is important to inspect and maintain the accessories and components of the formwork system, such as nuts, bolts, pins, and clamps. These should be regularly checked for any signs of wear, damage, or corrosion. If any issues are detected, the damaged or worn-out accessories should be replaced promptly. 7. Storage and Handling: Proper storage and handling of the steel frame formwork system is crucial for its longevity. The formwork should be stored in a dry and well-ventilated area to prevent moisture accumulation. Avoid stacking the frames excessively, as this can lead to deformation or damage. When handling the formwork, use appropriate lifting equipment and techniques to prevent accidents and minimize stress on the frames. By following these common maintenance and repair procedures, steel frame formwork systems can be kept in optimal condition, ensuring their longevity and reliability in construction projects.

- Q: How does steel frame formwork help in reducing construction time?

- Steel frame formwork helps in reducing construction time by providing a faster and more efficient method of constructing concrete structures. Firstly, steel frame formwork is lightweight and easy to handle, making it quicker to assemble and disassemble compared to traditional formwork systems. This saves time during the construction process as the formwork can be easily moved and reused across different areas of the site. Additionally, steel frame formwork is designed to be highly versatile and adaptable. It allows for the construction of various shapes, sizes, and configurations, enabling faster construction of complex structures. The formwork can be easily adjusted and modified to accommodate changes in design or construction requirements, reducing the time spent on alterations and adjustments. Moreover, steel frame formwork provides a high level of accuracy and precision. The rigid steel frames ensure consistent dimensions and alignment, resulting in accurate and uniform concrete structures. This eliminates the need for extensive rework and corrections, saving valuable time during the construction process. Furthermore, steel frame formwork offers faster curing times for concrete. The steel frames act as a heat sink, dissipating heat from the concrete, which accelerates the curing process. This enables faster removal of formwork, allowing for faster progression of construction activities. Lastly, steel frame formwork has a longer lifespan and can be reused multiple times, reducing the need for frequent replacements. This not only saves construction time but also reduces costs associated with purchasing and disposing of formwork materials. Overall, steel frame formwork offers several advantages that contribute to reducing construction time, including ease of handling, versatility, accuracy, faster curing times, and reusability. These factors make it a preferred choice for contractors looking to improve the efficiency and speed of their construction projects.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for projects with restricted construction timelines?

- When selecting the appropriate steel frame formwork system for projects with restricted construction timelines, there are several key considerations to keep in mind. Firstly, the system should be quick and easy to assemble and dismantle. Time is of the essence in such projects, so a formwork system that can be set up and taken down efficiently can help save valuable construction time. Secondly, the system should have a high load-bearing capacity to ensure structural stability and safety. It should be able to withstand the weight and pressure of the concrete being poured, even under tight timelines. Additionally, the formwork system should be versatile and adaptable to different project requirements. This includes having adjustable components that can accommodate various shapes, sizes, and heights, allowing for flexibility in design and construction. Furthermore, consider the availability and accessibility of the formwork system. It should be easily procurable and accessible within the project's location, avoiding delays caused by transportation or logistical challenges. Lastly, it is important to consider the durability and reusability of the formwork system. Projects with restricted timelines often require a fast-paced construction process, and using a durable and reusable system can help reduce costs and time spent on replacing or repairing formwork. Overall, selecting the appropriate steel frame formwork system for projects with restricted construction timelines involves considering factors such as ease of assembly and dismantling, load-bearing capacity, versatility, availability, durability, and reusability.

- Q: What are the different types of concrete testing and quality control methods used with steel frame formwork?

- Steel frame formwork utilizes various concrete testing and quality control methods to guarantee the strength, durability, and overall quality of the concrete used in construction projects. One widely used testing method is the slump test, which assesses the consistency and workability of the fresh concrete. This involves filling a cone-shaped mold with the concrete, compacting it, and then removing the mold to observe the slump or settlement of the concrete. This test determines if the concrete has the appropriate water-cement ratio and if it can be easily placed and compacted in the formwork. Another crucial method is the compressive strength test, which measures the concrete's ability to withstand compression or pressure. This test consists of casting concrete cylinders or cubes and subjecting them to a gradual increase in pressure until they fail. The test results determine if the concrete has reached the required strength for the specific application. Additionally, concrete mix design is an essential aspect of quality control. It involves determining the proportions of various materials like cement, aggregates, water, and admixtures to achieve the desired concrete properties. This process considers factors such as strength requirements, durability, workability, and environmental conditions. Furthermore, visual inspection of the formwork is conducted to ensure proper alignment and security, as well as to check for any leakage or defects that may affect the concrete pour. Non-destructive testing methods, like ultrasonic testing, can also be employed to assess the integrity and quality of the concrete without causing any damage to the structure. In conclusion, the combination of these concrete testing and quality control methods ensures that the concrete used with steel frame formwork meets the required standards and specifications. This guarantees the structural integrity and longevity of the construction project, resulting in a safe and reliable final outcome.

- Q: What are the safety precautions for using steel frame formwork in hazardous conditions?

- When using steel frame formwork in hazardous conditions, it is crucial to take certain safety precautions to ensure the well-being of workers. Here are some safety measures that should be followed: 1. Training and awareness: Workers should receive thorough training on the proper use of steel frame formwork in hazardous conditions. They should be educated about potential risks, such as falls, cuts, and strains, and how to mitigate these risks. 2. Personal protective equipment (PPE): All workers should wear appropriate PPE, including helmets, safety boots, gloves, and protective clothing. Safety glasses or goggles should be worn to protect the eyes from dust, debris, and other hazardous materials. 3. Inspection and maintenance: Regular inspection of the steel frame formwork should be conducted to identify any damage or defects that could compromise its integrity. Any issues should be addressed immediately, and damaged or worn-out components should be replaced. 4. Secure and stable setup: The steel frame formwork should be properly secured and stabilized to prevent accidental collapses. Adequate bracing and support systems should be in place, and the formwork should be securely anchored to the ground or supporting structure. 5. Fall protection: Workers should use fall protection equipment, such as harnesses, lanyards, and anchor points, when working at heights. Guardrails or safety nets should be installed to prevent falls from elevated platforms. 6. Proper lifting techniques: Workers should be trained in proper lifting techniques and should avoid overexertion. Mechanical lifting aids, such as cranes or hoists, should be used whenever possible to reduce the risk of strains or injuries. 7. Hazardous material handling: If hazardous materials are being used in conjunction with the steel frame formwork, proper handling procedures should be followed. Workers should be trained on the safe handling and storage of these materials, and any necessary precautions, such as ventilation or personal protective equipment, should be implemented. 8. Emergency preparedness: Adequate emergency plans should be in place, including evacuation procedures, first aid training, and access to emergency contact information. All workers should be familiar with these procedures and know how to respond in case of an emergency. By following these safety precautions, the use of steel frame formwork in hazardous conditions can be carried out with minimized risks and enhanced worker safety.

- Q: How does steel frame formwork affect the overall aesthetics of a concrete finish?

- The overall aesthetics of a concrete finish can be significantly impacted by steel frame formwork. By utilizing steel frame formwork, construction processes are guaranteed superior quality and precision resulting in a seamless and flawless finish. During the pouring and curing stages of concrete, the rigid steel frame acts as a support system, preventing any deformation or shifting. Not only does steel frame formwork provide a consistent and accurate formwork system, but it also allows for precise shaping and molding of concrete structures. This enables architects and designers to achieve their desired aesthetic vision without compromising. The use of steel frame formwork contributes to visually appealing and modern appearances with straight lines, sharp edges, and smooth surfaces. Moreover, steel frame formwork offers versatility and adaptability in design. It can be easily adjusted and customized to meet specific architectural requirements and desired finishes. Whether it involves creating unique patterns, textures, or intricate designs, steel frame formwork provides the necessary flexibility to achieve the desired aesthetic outcome. In addition to aesthetics, steel frame formwork enhances the durability and longevity of the concrete finish. The use of steel ensures structural integrity and strength, preventing any potential damage or deterioration over time. This means that the concrete finish will maintain its aesthetic appeal for a longer period, reducing the need for frequent maintenance or repairs. Overall, steel frame formwork plays a critical role in shaping and enhancing the aesthetics of a concrete finish. It provides a solid foundation, precision, and versatility, allowing for the creation of visually pleasing and durable architectural designs.

- Q: Can steel frame formwork be used in tight construction spaces?

- Yes, steel frame formwork can be used in tight construction spaces. Steel frame formwork is known for its strength and durability, which allows it to withstand high pressure and provide stability during the concrete pouring process. Additionally, steel frame formwork is highly versatile and can be easily adjusted and customized to fit different construction spaces, including tight or limited areas. The modular design of steel frame formwork allows for easy assembly and disassembly, making it a suitable choice for tight construction spaces where traditional formwork systems may not be feasible. Overall, steel frame formwork can be an effective solution for constructing in tight spaces, providing the necessary support and stability while maximizing the available area.

- Q: Can steel frame formwork be used for both large and small-scale construction projects?

- Steel frame formwork is applicable to construction projects of both large and small scales. It is renowned for its durability and strength, which renders it suitable for various construction projects, irrespective of their size. Stability and support are guaranteed by the steel frame, ensuring that the formwork can endure the pressure and load of the concrete during the casting process. Moreover, the design of steel frame formwork allows for flexibility and easy assembly and disassembly, enabling efficient utilization in projects of different sizes. Its reusability makes it a cost-effective solution for both large and small-scale projects since it can be used multiple times. In conclusion, steel frame formwork is a versatile and dependable option for construction projects of any magnitude.

Send your message to us

Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches