Steel Frame Formwork with Adustable Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

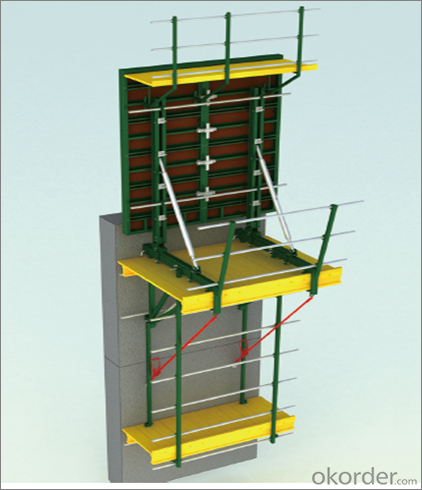

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

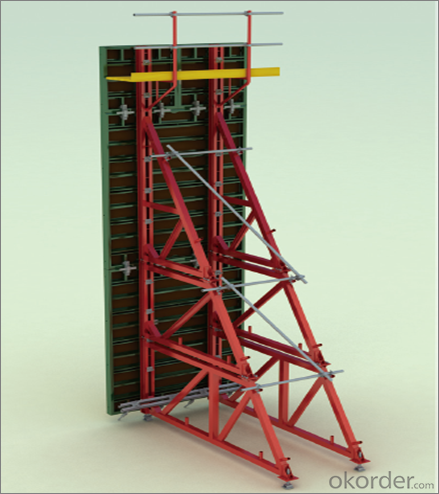

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Does steel frame formwork require any specific training for installation?

- Installation of steel frame formwork requires specific training. This complex system involves precise assembling and installation processes, making it crucial for installers to possess the necessary knowledge and skills to ensure safety and effectiveness. Training for steel frame formwork installation typically includes learning how to interpret technical drawings and specifications, as well as familiarizing oneself with the various components and materials used in the formwork system. Installers are taught proper handling, lifting, and positioning techniques for steel frames, as well as the correct methods for connecting and securing formwork panels and accessories. Moreover, training encompasses important safety procedures and measures that must be followed during installation, such as wearing personal protective equipment and ensuring the stability and structural integrity of the formwork. Understanding the load capacities and limitations of the steel frame formwork system is also crucial to avoid potential accidents or structural failures. In conclusion, specific training for steel frame formwork installation is indispensable. It guarantees correct installation, compliance with standards and specifications, and provides a safe and stable support for concrete construction projects.

- Q: What are the different types of accessories available for steel frame formwork?

- There are several types of accessories available for steel frame formwork, including form ties, walers, push-pull props, scaffolding, corner brackets, scaffolding brackets, formwork clamps, spreader bars, and adjustable beam clamps. These accessories help to enhance the stability and functionality of the formwork system, ensuring precise and efficient concrete construction.

- Q: Does steel frame formwork require any specific safety measures during installation?

- Yes, steel frame formwork does require specific safety measures during installation. Some of the key safety measures that should be followed include: 1. Proper training: All personnel involved in the installation of steel frame formwork should receive appropriate training on how to handle and install the formwork safely. This includes understanding the equipment, its components, and the correct installation procedures. 2. Personal protective equipment (PPE): Workers should wear the necessary PPE such as helmets, safety goggles, gloves, and steel-toed boots to protect themselves from potential hazards such as falling objects, sharp edges, and impact injuries. 3. Secure installation: The formwork should be securely installed to prevent any instability or collapse during construction activities. This may involve using adequate bracing, tie rods, clamps, and other fastening systems to ensure the stability of the formwork structure. 4. Inspection and maintenance: Regular inspection and maintenance of the formwork are crucial to identify any defects, damages, or weaknesses that can compromise its safety. Any issues should be promptly addressed and repaired before further use. 5. Safe access and egress: Proper access and egress routes should be provided to ensure safe movement of workers during installation. This may include the use of ladders, scaffolding, or other appropriate means of access. 6. Load capacity: The formwork should be designed and installed to withstand the expected loads during construction activities. Overloading should be avoided, and the maximum load capacity of the formwork should be clearly communicated and adhered to. 7. Coordination and communication: Effective communication and coordination among all workers involved in the installation process are essential to ensure safe working conditions. This includes clear instructions, proper signage, and regular safety briefings. By following these specific safety measures, the risk of accidents, injuries, and structural failures can be significantly reduced during the installation of steel frame formwork.

- Q: Can steel frame formwork be used for both internal and external concrete walls?

- Yes, steel frame formwork can be used for both internal and external concrete walls. Steel frame formwork is a versatile and durable system that is commonly used in construction for various types of structures, including walls. It provides a strong framework for pouring and shaping concrete, ensuring proper alignment and stability during the construction process. The steel frames can be easily assembled and disassembled, making it suitable for both internal and external walls where different formwork configurations may be required. Additionally, steel frame formwork can be easily adjusted to accommodate varying wall thicknesses and heights, allowing for flexibility in design and construction. Overall, steel frame formwork is a reliable and cost-effective solution for creating both internal and external concrete walls.

- Q: How does steel frame formwork handle the placement of embedded items, such as electrical conduits or plumbing pipes, within the concrete structure?

- Steel frame formwork allows for the easy placement of embedded items within the concrete structure. It provides precise and accurate positioning of electrical conduits or plumbing pipes, ensuring they are securely placed in the desired location. The steel frames act as a guide, providing support and stability during the concrete pouring process, ensuring that the embedded items are not displaced or damaged.

- Q: How does steel frame formwork handle the placement of concrete in overhead structures or ceilings?

- Steel frame formwork is a versatile and efficient system for handling the placement of concrete in overhead structures or ceilings. This method of formwork offers multiple advantages, making it suitable for various construction projects. Firstly, the steel frame formwork provides excellent strength and durability, ensuring the safe and reliable support of the concrete during the pouring process. Its robust structure can withstand the weight of the wet concrete, preventing any collapse or deformation that could compromise the integrity of the overhead structure or ceiling. Furthermore, steel frame formwork is designed with adjustable components, allowing for flexibility in adapting to different shapes and sizes of overhead structures or ceilings. The modular nature of the system enables easy customization and quick assembly, saving time and resources during the construction process. In addition, steel frame formwork is highly reusable, making it a cost-effective solution for multiple projects. The steel frames can be disassembled and reassembled easily, reducing the need for additional formwork materials and reducing waste. This not only saves money but also contributes to sustainable construction practices. Moreover, the steel frame formwork provides a smooth and even surface finish to the concrete, ensuring a high-quality end result. The precise alignment and tight joints of the steel frames help eliminate any potential defects or imperfections, resulting in a visually appealing and structurally sound overhead structure or ceiling. Overall, steel frame formwork is a reliable and efficient method for handling the placement of concrete in overhead structures or ceilings. Its strength, flexibility, reusability, and ability to provide a smooth finish make it an ideal choice for construction projects where safety, efficiency, and quality are paramount.

- Q: Can steel frame formwork be used in projects with restricted material availability?

- Steel frame formwork can be a suitable option for projects with restricted material availability. The use of steel frame formwork offers several advantages in such situations. Firstly, steel is a durable and robust material that can withstand harsh conditions and heavy loads, making it suitable for various construction projects. Additionally, steel formwork can be reused multiple times, reducing the need for frequent material replacements. This feature is particularly beneficial in projects with limited access to construction materials. Moreover, steel frame formwork can be easily transported and assembled, allowing for efficient construction even in areas with restricted material availability. Overall, the use of steel frame formwork can be a practical solution for projects with limited material resources, ensuring cost-effectiveness and timely completion.

- Q: Are there any limitations or disadvantages to using steel frame formwork?

- Yes, there are some limitations and disadvantages to using steel frame formwork. One limitation is the high initial cost of steel frame formwork compared to other types of formwork, such as timber formwork. Steel is more expensive to purchase and requires specialized tools and equipment for installation and removal. This can make it less cost-effective for small-scale construction projects or projects with tight budgets. Another disadvantage is the weight of steel frame formwork. Steel is a heavy material, which can make it difficult to handle and transport. This can slow down the construction process and require additional labor and equipment to move and position the formwork. Steel frame formwork also requires skilled labor for installation and removal. The assembly and disassembly of steel formwork can be complex and time-consuming, requiring workers with specialized training and experience. This can increase labor costs and potentially lead to delays in the construction schedule. In addition, steel formwork is not as flexible as other types of formwork. Once the steel frame is fabricated, it cannot be easily modified or adjusted to accommodate design changes or variations in the construction process. This lack of flexibility can be a disadvantage if there are unforeseen changes or adjustments needed during the construction project. Lastly, steel frame formwork may not be suitable for all types of construction projects. It is more commonly used for large-scale projects where the benefits of steel, such as its strength and durability, outweigh the limitations and disadvantages. For smaller or simpler construction projects, alternative formwork systems may be more cost-effective and efficient. Overall, while steel frame formwork offers advantages in terms of strength and durability, it does have limitations and disadvantages that need to be considered when choosing the appropriate formwork system for a construction project.

- Q: What are the different types of support beams used with steel frame formwork?

- There are several types of support beams commonly used with steel frame formwork. These include H-beams, I-beams, channel beams, and box beams. H-beams are often used for heavy-duty applications due to their high load-bearing capacity. I-beams are suitable for long-span structures and offer excellent strength-to-weight ratio. Channel beams are often used for lighter loads and offer versatility in terms of connection options. Box beams are hollow and provide high stiffness and resistance to bending. Ultimately, the type of support beam chosen depends on the specific requirements of the construction project.

- Q: How does steel frame formwork handle the placement of reinforcement bars?

- Steel frame formwork is a versatile system that allows for easy handling and placement of reinforcement bars. The formwork is designed with pre-determined openings and slots, which provide convenient spaces for the positioning of reinforcement bars. These openings ensure accurate placement, alignment, and spacing of the bars, resulting in a sturdy and durable structure. Additionally, the steel frame formwork provides a stable and secure platform for workers to efficiently install the reinforcement bars, ensuring their proper integration with the formwork system.

Send your message to us

Steel Frame Formwork with Adustable Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords