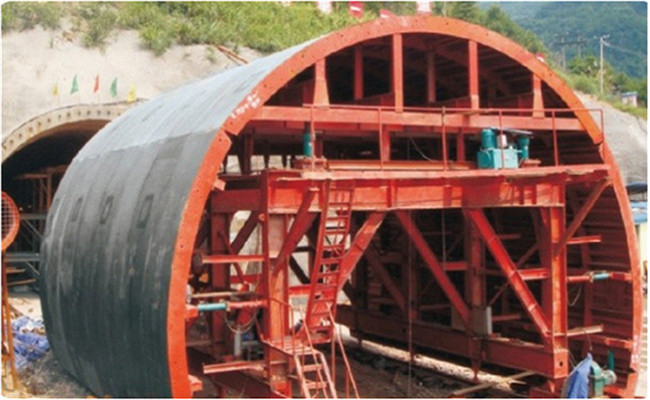

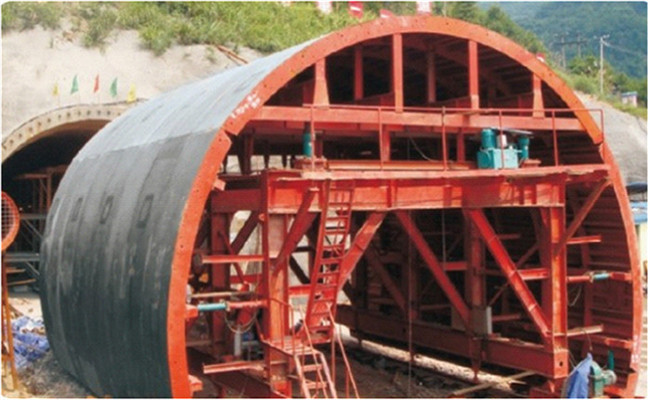

Tunnel Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction & Application:

● Keep suitable formwork strength, make the vault and side wall be smooth in the secondary lining operation.

● Limitedly analysis and calculate the stress to optimize the structure, which can guarantee the strength and stiffness, and also reduce the steel consumption and construction cost.

● Implement standardization renovation, use standard component, promote its versatility and improve repeated utilization factor.

Features:

①Good concrete quality

With full steel materials, high load bearing capacity and stiffness is achieved, that makes perfect concrete surface.

②High-speed of installation and removal of the form

The formwork is fully hydraulic, with hydraulic cylinder to prop & strip, and lock mechanically.

③Easy operation and safety

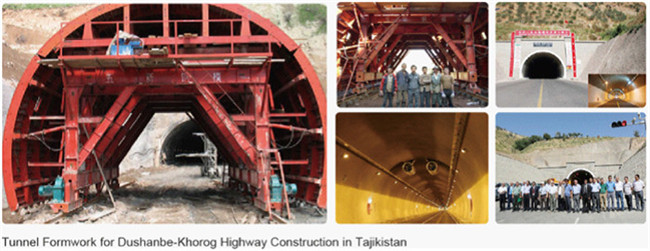

Projects:

- Q: How the tunnel template is calculated

- According to the experience and the reuse rate of the template, the thickness of the single lane tunnel template is 10mm, the thickness of the single three lane template is 12mm, and the thickness of the one-way tunnel is 15mm. Consider the length of the template and the construction of the impact of general 10m, not more than 12 meters.

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- According to the actual situation of your project

- Q: How the arch of the tunnel concrete pouring up, how to support before pouring, using I-beam is directly support the earth?

- Small pipe or large, medium pipe shed is the advanced support for the broken rock area or into, out of the hole, of course, grouting, grouting without losing the significance of the implementation.

- Q: I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- According to the design requirements, draw the spare parts drawings, and then workers in accordance with the production drawings!

- Q: What are the reasons for the two lining concrete lining of the tunnel?

- (1) the steel frame is put aside, there is no reinforcement pad or pad number is not enough, the position is not correct, resulting in the reinforcement close to the template and exposed.(2) the coarse aggregate size is greater than the reinforcement spacing, or the debris is placed in the steel frame, while the concrete leakage, forming a serious honeycomb and holes and exposing the reinforcement.

- Q: What is the width of a ring in a tunnel

- Generally used in the tunnel as a two car lining template

- Q: Main diseases and prevention of tunnel

- Main diseases and prevention of tunnel1 over excavation in tunnel excavationPhenomenon: in tunnel excavation, the upper, lower, left and right contours are exceeded.The reason analysis: the measurement is not allowed, the deviation is big; the hole position deviation is bigger; the hole in the hole drilling process does not have the straight hole to have the slanting hole to exceed the limit; the blasting parameter choice is wrong, the charge quantity is too much or unreasonable.Preventive measures: to ensure the measurement work turnover review system; accurate calculation of blasting parameters, the formal process test before entering the tunnel, timely adjust the parameters change of geological condition; hole position and direction control in drilling process.

- Q: A detailed method is introduced

- 1 overall construction planUsing the new Austrian tunneling method, the construction principle is "less disturbance, early spray anchor, ground measurement, tight closure". The rock excavation method of construction; rock class micro bench excavation, pre splitting blasting; IV surrounding rock by construction method (Section IV surrounding rock under the partial, the construction step method), smooth blasting technique; fault fracture zone by middle wall construction method.The ballast is unloaded by the side unloading loader.Two lining the rail trolley, concrete mixing truck to transport concrete, pumping concrete, lining after decoration engineering construction.It is necessary to strengthen the geological prediction in the fault fracture zone and water rich zone, and provide the basis for the construction.

- Q: What is the concrete construction of the tunnel invert

- The construction of concrete is related to the non - construction concrete

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- There is two times of lining concrete pouring, the normal price is within 100 yuan, this is the pure artificial price, does not contain steel trolley and various materials two tunnel lining.

Send your message to us

Tunnel Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords