120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 120 Steel frame formwork-column formwork

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of 120 Steel frame formwork-Column formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

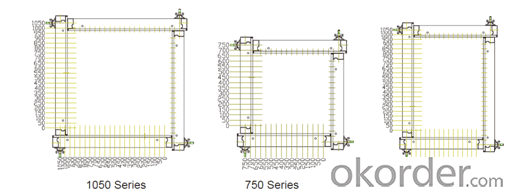

3. 120 Steel frame formwork-column formwork Images

4. 120 Steel frame formwork-Column Formwork Specifications

1050 Series /750 Series Adjustable Column Formwork

5. FAQ of 120 Steel frame formwork-column formwork

1) What can we do for you?

.We can ensure the quality of the120 Steel frame formwork-column formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of early prop head formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel frame formwork be used for post-tensioned concrete structures?

- Yes, steel frame formwork can be used for post-tensioned concrete structures. Post-tensioning is a technique used to reinforce concrete structures by applying tension to steel cables or bars after the concrete has hardened. Steel frame formwork provides a strong and durable framework for pouring and shaping the concrete during construction. It can easily accommodate the additional forces and requirements of post-tensioning. The steel frame formwork, along with the post-tensioning elements, work together to create a structurally sound and reinforced concrete structure.

- Q: How does steel frame formwork support the construction of slabs and beams?

- Steel frame formwork is a system that provides support and structure during the construction of slabs and beams. It consists of steel frames that are assembled and secured together to create a sturdy framework. This framework acts as a mold into which concrete is poured and left to harden, forming the slab or beam. The steel frame formwork ensures the correct dimensions, shape, and alignment of the slabs and beams, while also providing the necessary support to withstand the weight and pressure exerted by the concrete and any subsequent loads.

- Q: What are the different types of edge protection systems used with steel frame formwork?

- There are several types of edge protection systems that can be used with steel frame formwork to ensure the safety of workers and prevent falls or accidents. These systems are designed to create a barrier or guardrail around the edges of the formwork, providing a secure working environment. One type of edge protection system commonly used with steel frame formwork is the handrail system. This system consists of metal or plastic handrails that are attached to the frame of the formwork. The handrails act as a barrier, preventing workers from accidentally falling off the edges of the formwork. Handrail systems are typically easy to install and can be adjusted to fit different formwork configurations. Another type of edge protection system is the toe board system. Toe boards are horizontal barriers that are installed along the bottom edge of the formwork. They are designed to prevent tools, materials, or debris from falling off the formwork and potentially injuring workers below. Toe boards are usually made of metal or wood and can be easily attached to the frame of the formwork. Additionally, some edge protection systems include mesh panels or safety nets. These systems provide a physical barrier around the edges of the formwork, preventing workers from accidentally falling off. Mesh panels or safety nets are usually made of strong, durable materials and are securely attached to the frame of the formwork. They can be easily installed and removed as needed. Lastly, some edge protection systems include a combination of handrails, toe boards, and mesh panels or safety nets. These comprehensive systems offer multiple layers of protection and are often used in larger construction projects or areas with higher risks of falls or accidents. Overall, the different types of edge protection systems used with steel frame formwork serve the common purpose of ensuring worker safety and preventing falls or accidents. The specific type of system used will depend on the requirements of the project and the level of protection needed.

- Q: What are the different types of bracing systems used in steel frame formwork?

- Steel frame formwork commonly utilizes several types of bracing systems to ensure stability and support during construction. One such system is diagonal bracing, where diagonal members are strategically placed between vertical and horizontal members of the steel frame. This arrangement helps distribute the load evenly and provides lateral stability to the formwork. Another system is cross bracing, which involves diagonal members placed in a crisscross pattern between vertical and horizontal members. This type of bracing enhances the formwork's rigidity and strength, especially in areas with higher loads. For larger formwork structures like multi-story buildings, a portal bracing system is often employed. It consists of interconnected vertical and horizontal members forming a portal shape, offering additional stability and support. In some cases, adjustable components like turnbuckles or threaded rods may be incorporated into bracing systems. These allow for easy adjustment and tightening of bracing members, ensuring the formwork remains stable and secure throughout the construction process. In summary, the various types of bracing systems employed in steel frame formwork serve the purpose of providing stability, support, and strength. Each system offers unique advantages and is selected based on the specific requirements of the construction project.

- Q: How does steel frame formwork ensure proper concrete consolidation and compaction?

- Steel frame formwork ensures proper concrete consolidation and compaction by providing a rigid structure that holds the concrete in place during the pouring and curing process. The steel frame acts as a support system, preventing the concrete from sagging or deforming under its own weight. This ensures that the concrete remains in the desired shape and form, allowing for effective consolidation and compaction. Additionally, the steel frame formwork allows for the use of vibration equipment, which helps to further consolidate the concrete, removing any air voids and ensuring uniform compaction throughout the structure. Overall, steel frame formwork plays a crucial role in maintaining the integrity and quality of the concrete during the construction process.

- Q: How does steel frame formwork handle different types of formwork edge protection?

- Construction projects can benefit from the versatility and durability of steel frame formwork, which includes various options for formwork edge protection. This framework provides a robust and reliable structure that easily integrates with different types of formwork edge protection systems. One commonly used method with steel frame formwork is the attachment of timber or plywood boards. These boards are firmly fixed to the steel frame using screws or nails, creating a solid barrier along the edges of the formwork. This approach is cost-effective and straightforward, as timber or plywood boards are easily accessible and can be easily cut to the desired lengths. Another option for formwork edge protection with steel frame formwork is the installation of steel or aluminum guardrails. These guardrails are specifically designed for edge protection and securely fasten to the steel frame using clamps or brackets. Compared to timber or plywood boards, steel or aluminum guardrails offer superior safety and durability, making them suitable for projects that require enhanced protection. Steel frame formwork can also accommodate other types of edge protection systems, such as plastic or rubber safety barriers. These barriers are lightweight, easy to install, and provide flexibility for formwork edge protection. Depending on the project's specific requirements, these barriers can be attached to the steel frame using various methods, including clamps, brackets, or adhesive. In summary, steel frame formwork effectively accommodates different formwork edge protection systems. Whether using timber boards, steel or aluminum guardrails, or plastic safety barriers, the sturdy construction of the steel frame ensures secure placement of the formwork edge protection, creating a safe working environment for construction workers.

- Q: Can steel frame formwork be used for educational and institutional buildings construction?

- Educational and institutional buildings can benefit greatly from the use of steel frame formwork. This construction method is versatile and durable, making it a popular choice for various types of structures. One advantage of steel frame formwork is its strength and reliability. It can withstand heavy loads and provide structural stability, which is particularly important in buildings where the safety of occupants is a priority. Another advantage is the flexibility it offers in design and construction. Steel frame formwork can be easily adjusted and modified to meet different architectural requirements and functional needs. This is especially beneficial in educational buildings, where spaces like classrooms and laboratories may need to be reconfigured or expanded in the future. In addition, steel frame formwork is a time-efficient construction method. The prefabricated steel frames can be quickly assembled on-site, reducing overall construction time. This is crucial in educational and institutional buildings, where strict deadlines must be met, such as the start of a new academic year or the opening of a new facility. In conclusion, steel frame formwork is an efficient and suitable construction method for educational and institutional buildings. Its strength, flexibility, and time-saving qualities make it an ideal choice for these types of structures.

- Q: Are there any restrictions on the formwork height that can be achieved with steel frame formwork?

- There are no specific restrictions on the formwork height that can be achieved with steel frame formwork. Steel frame formwork is known for its strength and durability, allowing it to support higher heights compared to other types of formwork systems. However, the maximum achievable formwork height may depend on various factors such as the design of the steel frame system, the type of support structure used, and the load-bearing capacity of the surrounding structure. It is important to consult with structural engineers and formwork manufacturers to determine the appropriate formwork height based on the specific project requirements and safety standards.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for complex structures?

- When selecting the appropriate steel frame formwork system for complex structures, there are several key considerations to keep in mind. First and foremost, it is important to assess the specific requirements and complexity of the structure. This includes factors such as the size, shape, and height of the structure, as well as any unique design features or challenges that may be present. Understanding the complexity of the structure will help determine the level of flexibility, adaptability, and customization required from the formwork system. Next, the load-bearing capabilities of the formwork system must be carefully evaluated. Complex structures often involve heavier loads and increased stresses, so it is crucial to select a steel frame formwork system that can handle the expected loads effectively and safely. This includes considering factors such as the strength, rigidity, and stability of the system. Another important consideration is the ease of assembly and disassembly of the formwork system. Complex structures often require intricate formwork configurations, so selecting a system that is easy to assemble and adjust will significantly improve productivity and efficiency on site. Additionally, the formwork system should have the capability to accommodate any necessary modifications or alterations during the construction process. The durability and lifespan of the formwork system should also be taken into account. Complex structures typically involve extended construction periods, so selecting a steel frame formwork system that is durable and can withstand prolonged use without compromising its structural integrity is essential. This includes considering factors such as the quality of materials, corrosion resistance, and maintenance requirements. Finally, cost-effectiveness is an important consideration. While complex structures may require specialized formwork systems, it is crucial to evaluate the cost-benefit ratio and select a system that offers the best value for money in terms of performance, durability, and productivity. In summary, when selecting the appropriate steel frame formwork system for complex structures, key considerations include assessing the complexity of the structure, evaluating load-bearing capabilities, considering ease of assembly and disassembly, ensuring durability and lifespan, and maintaining cost-effectiveness.

- Q: What are the different types of form stripping methods used with steel frame formwork?

- There are several types of form stripping methods used with steel frame formwork, including crane stripping, hydraulic stripping, and manual stripping. Crane stripping involves using a crane to lift and remove the formwork panels, while hydraulic stripping utilizes hydraulic systems to detach the formwork from the concrete structure. Manual stripping, on the other hand, involves manually dismantling the formwork components. These different methods offer flexibility and efficiency in the formwork removal process, depending on the project requirements and available resources.

Send your message to us

120 Type Steel Frame Formwork for Column Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords