Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Column Steel Frame Formwork Description

With adjustable flexiable sizes of frame, the column steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean with column formwork. As the framework, it is adapted to the plywood with thickness of 18mm. High-precision production line guarantees the perfect products.

2. Main Features of Column Steel Frame Formwork

◆ Allowable pressure is 80KN/m2 .

◆ Faster and easy operation.

◆ The dimension for column is adjustable.

- We can special design according to any requirements.

3. Column Steel Frame Formwork Specifications

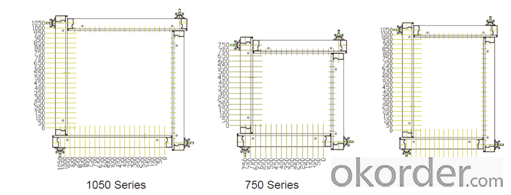

4. Column Steel Frame Formwork Images

5. FAQ of Column Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: What are the different types of formwork anchors used with steel frame formwork systems?

- Different types of formwork anchors used with steel frame formwork systems include threaded anchors, wedge anchors, and plate anchors. Threaded anchors are typically used for smaller formwork applications and are designed to be screwed into the steel frame. Wedge anchors are commonly used for larger formwork applications and rely on the expansion of a wedge inside the concrete to provide secure attachment. Plate anchors are used when a larger surface area is required for load distribution and are typically bolted or welded to the steel frame.

- Q: Does steel frame formwork require any specific tools for installation?

- Yes, steel frame formwork typically requires specific tools for installation. Some of the common tools needed include adjustable spanners, wrenches, mallets, hammers, screwdrivers, pliers, and measuring tapes. Additionally, specialized tools such as formwork clamps, tie rods, cones, and formwork release agents may also be required depending on the specific project requirements. These tools are essential for assembling, adjusting, and securing the steel frames together, ensuring proper alignment and stability during the concrete pouring process.

- Q: How does steel frame formwork impact the overall constructability of a project?

- Steel frame formwork can greatly enhance the overall constructability of a project. Its rigidity and strength allow for efficient and precise concrete placement, ensuring consistent and accurate shaping of the structure. Additionally, steel frame formwork offers quick assembly and disassembly, reducing construction time and enabling faster project completion. Its versatility enables complex shapes and designs, promoting architectural flexibility. Overall, steel frame formwork enhances construction efficiency, quality, and durability, positively impacting the overall success of the project.

- Q: What are the common quality control inspections for steel frame formwork installations?

- Some inspections commonly performed to ensure the quality of steel frame formwork installations are as follows: 1. Dimensional Accuracy: In order to confirm that the steel frames are fabricated according to the design drawings, an inspection is conducted to verify their dimensions and specifications. This involves checking the lengths, widths, and heights of the frames to ensure they meet the required tolerances. 2. Welding Inspection: Since steel frames are often assembled through welding, it is essential to conduct a thorough inspection to ensure the quality and strength of the joints. This inspection includes examining the welds for proper penetration, alignment, and absence of defects such as cracks or porosity. 3. Surface Quality: The surface of the steel frames must be free from any defects that could affect their performance or durability. An inspection is performed to check for rust, corrosion, burrs, sharp edges, or any other imperfections that could impact the functionality of the formwork. 4. Alignment and Levelness: Accurate installation of the steel frames requires inspecting their alignment and levelness. Laser levels, plumb bobs, or other measuring tools are used to examine the vertical and horizontal alignment of the frames. 5. Anchorage Inspection: Steel formwork frames are commonly anchored to the structure using various methods, such as bolts or concrete embeds. An inspection is conducted to ensure the adequacy and proper installation of these anchorages, ensuring the stability and safety of the formwork system. 6. Load Capacity Testing: To ensure that the steel frame formwork installations can support the intended loads without failure or deformation, load capacity testing is performed. This involves applying the expected loads to the formwork system and monitoring its response to ensure it meets the required strength and stability criteria. 7. Safety Inspection: Compliance with safety standards and regulations is crucial for formwork installations. A thorough inspection is conducted to verify the presence and proper installation of safety features such as handrails, toe boards, and access platforms. Additionally, it ensures that all workers involved in the installation are using appropriate personal protective equipment. These inspections are carried out during various stages, including fabrication, assembly, and installation of the steel frame formwork. They play a vital role in ensuring the quality, reliability, and safety of the formwork system, minimizing the risk of accidents, delays, or structural failures during the construction process.

- Q: When the steel frame tube structure adopts a rectangular plane, its aspect ratio should not be greater than the number of

- Light steel structure is mainly used in the construction of large load bearing

- Q: What is the maximum permissible load on steel frame formwork support systems?

- The maximum permissible load on steel frame formwork support systems can vary depending on several factors, including the specific design and construction of the support system, as well as the intended use and load requirements of the formwork. Generally, steel frame formwork support systems are designed to withstand significant loads, as they need to support the weight of the formwork, concrete, and any additional loads imposed during the construction process. However, it is important to consult the manufacturer's specifications and guidelines for the specific support system being used, as they will provide the most accurate information regarding the maximum permissible load. Additionally, it is crucial to consider the load distribution and ensure that the load is evenly distributed across the support system to prevent any localized stress points or overloading. Proper engineering and structural analysis should be carried out to determine the maximum permissible load on the steel frame formwork support systems for a particular construction project. Ultimately, it is recommended to consult with a qualified structural engineer or the manufacturer of the support system to determine the maximum permissible load for a specific steel frame formwork support system, taking into account the project's requirements and specifications.

- Q: Can steel frame formwork be used in projects with limited skilled labor availability?

- Yes, steel frame formwork can be used in projects with limited skilled labor availability. Steel frame formwork is designed to be easy to assemble and dismantle, making it suitable for projects where skilled labor is limited. Additionally, steel frame formwork is durable and can be reused multiple times, further reducing the need for skilled labor.

- Q: What are the different types of formwork connections used with steel frame formwork?

- There are several different types of formwork connections that can be used with steel frame formwork. These connections are designed to securely join the formwork panels together, ensuring stability and strength during the concrete pouring process. Some of the commonly used types of formwork connections include: 1. Wedge connections: These connections use steel wedges that are inserted into pre-drilled holes in the formwork panels. The wedges are then tightened to securely hold the panels together. 2. Bolted connections: Bolted connections involve using bolts, nuts, and washers to join the formwork panels. Holes are drilled in the panels and bolts are inserted through them. Nuts and washers are then tightened to hold the panels securely in place. 3. Pin and wedges connections: This type of connection involves using steel pins and wedges. The pins are inserted into holes in the formwork panels and wedges are driven into the slots on the pins to hold the panels together. 4. Clamping connections: Clamping connections use clamps or clamping devices to join the formwork panels. These clamps are tightened around the panels, applying pressure to hold them securely together. 5. Magnetic connections: Magnetic connections utilize magnets embedded within the formwork panels to hold them together. These magnets create a strong bond between the panels, eliminating the need for additional connectors. 6. Hook and loop connections: Hook and loop connections involve using straps with hook and loop fasteners to join the formwork panels. These straps are wrapped around the panels, providing a secure connection. Each type of formwork connection has its own advantages and disadvantages, and the choice of connection depends on factors such as the specific project requirements, the formwork system being used, and the desired level of ease and speed of assembly.

- Q: Can steel frame formwork be used for high-strength concrete?

- Yes, steel frame formwork can be used for high-strength concrete. Steel frame formwork is known for its strength and durability, making it suitable for handling high-strength concrete. The rigid structure of the steel frame provides stability and support, ensuring that the formwork can handle the pressure exerted by the high-strength concrete. Additionally, steel frame formwork allows for precise and accurate placement of the concrete, ensuring that the desired strength requirements are met. However, it is important to consider the design and specifications of the steel frame formwork to ensure that it is compatible with the specific requirements of high-strength concrete. Proper reinforcement and bracing may be necessary to ensure the formwork can withstand the increased loads associated with high-strength concrete.

- Q: What types of accessories are available for steel frame formwork?

- The functionality and efficiency of steel frame formwork can be enhanced through the use of various types of accessories. Some commonly used accessories are: 1. Wedges and clamps: These accessories secure the steel formwork panels together, ensuring stability and preventing any movement during the concrete pouring process. 2. Formwork ties: Used to connect the formwork panels to each other and to the vertical and horizontal supports, these accessories provide structural integrity and help maintain the desired shape and dimensions of the concrete structure. 3. Formwork stay systems: These accessories support the formwork panels, preventing deformation or displacement caused by the pressure exerted by the wet concrete. They contribute to the additional strength and stability of the formwork structure. 4. Formwork brackets: Supporting the formwork panels at the desired height, these accessories maintain the required level and alignment during the concrete pouring process. 5. Formwork corner pieces: These accessories allow for the creation of corners and angles in the formwork structure, enabling the construction of various shapes and designs. 6. Formwork release agents: Applied to the formwork surface, these agents prevent the concrete from adhering to the steel frame, ensuring easy removal of the formwork once the concrete has cured. 7. Formwork spacers: These accessories maintain the required spacing between the formwork panels, ensuring uniformity and consistency in the concrete structure. 8. Formwork accessories for specific applications: Depending on the project requirements, there are specialized accessories available for specific applications, such as adjustable formwork props, scaffolding systems, and safety equipment. In summary, these accessories are crucial in enhancing the efficiency, durability, and safety of steel frame formwork systems, enabling the construction of high-quality concrete structures.

Send your message to us

Steel Frame Formwork for Column Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords