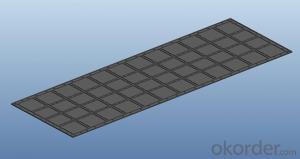

Plane Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Haiyuan New Material possesses china’s first fully automatic long fiber reinforced thermoplastic composite mould pressing production line with independent intellectual property, referred to as LFT-D line.

Why we developed EANTE formwork?

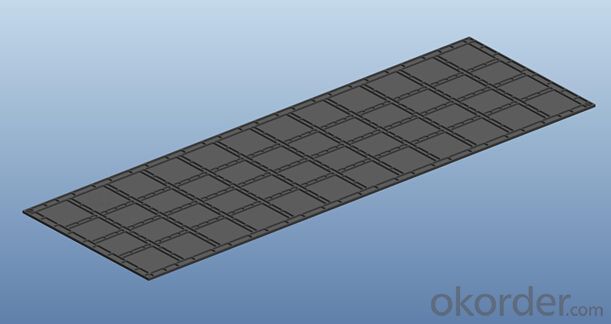

Superiority:

General worker can assemble and remove easily, save more labor cost.

The reinforcing ribs of EANTE formwork can be used to instead of the steel tube and wood.

Preassemble the EANTE formwork in the factory and fix it in the construction location.

The size accuracy of the composite formwork is better than that of the steel formwork and the wooden formwork. The concrete surface cast by EANTE Formwork is quite smooth, without any flaw, and no release agent is applied to assist the formwork removing.

We developed our own software with the characteristics as follow:

a. Computation time: it depends on the complexity of the architecture drawing;

b. Construction drawing: it is shifted from assembling drawing easily;

c. Material list: the assembling designing software would generate a list of formwork elements and auxiliary products.

Enviromental: EANTE Formwork is made from composite material, which is low carbon, recyclable and environment-friendly.

Saftness: The labor, large equipment, electric saws and iron nails are used much less on the building site, which leads to simplified on-site management and the safer construction.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- This is mainly to see how the use of workers in the process of operation by standard, 50 times is entirely possible. The use of plastic templates a little bit, the most important thing is to focus on cost savings, integrated plastic template cost is the lowest. But the price is more expensive than the wood template, long-term, large-scale use is cost-effective.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- With PVC board and steel ceiling of the board on it, to the hardware store to buy

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

Send your message to us

Plane Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords