Easy Removable Plastic Formwork - Column Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

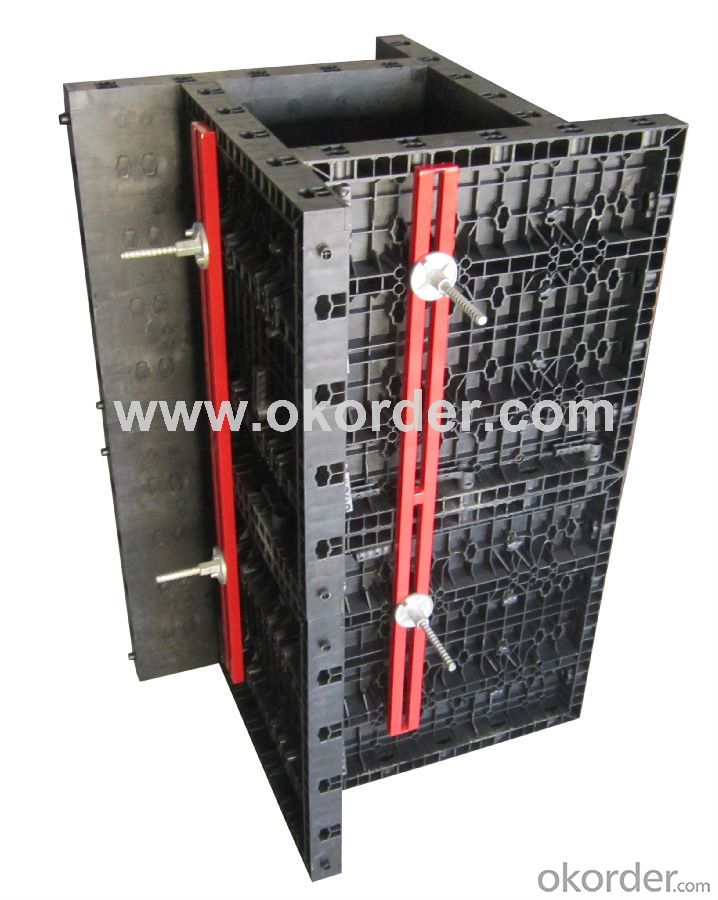

Easy Removable Plastic Formwork - Column Formwork

The column panels are interconnected using the standard nylon locking handles. Each panel will require 9 handles. The forming face has 6 parallel rows of fixing holes to allow the orthogonal connection of the panels in a “star” shape. The rows are placed at a distance of 100/50mm the one from the other, allowing the forming of square and/or rectangular columns with side of 150 to 600mm.

Set Up Easily

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system needn’t traditional wood blocks and nails.

The panels have holes to fit tie rod, guarantee the strength of the whole system.

Easy Treatment after Pouring

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

Corner & Specification

Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily.

product name | Modular formwork |

origin | China |

color | Black |

material | PP |

weight | 11kg |

tensile strength | 40KN |

reusable | 100 times |

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- Is the template based on your product requirements, can you talk about the requirements of each part of your product?

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

Easy Removable Plastic Formwork - Column Formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords